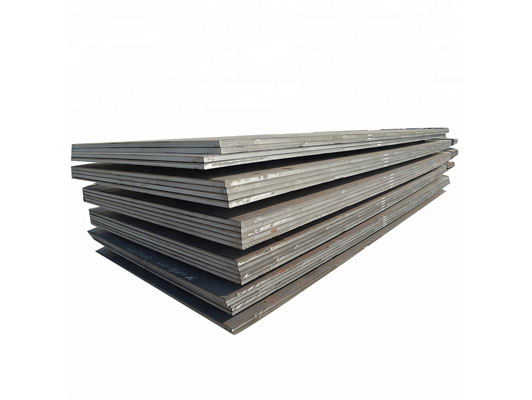

Hot Rolled Strip

Description of Hot Rolled Steel Strip

Hot rolled stripgenerally refers to a coiled steel strip having a thickness of 1 to 20 mm, and the width is generally 600 to 2000 mm. The hot rolled steel strip can be used directly as a hot rolled steel sheet, or a cold rolled strip can be supplied as a billet. Widely used in automotive, electrical, chemical, shipbuilding, and other industrial sectors, but also as a billet for cold rolled, welded pipe, cold-formed steel production. Strip hot strip mill is the main equipment for producing hot rolled steel strip, which has the advantages of high production efficiency, high output, and good quality.

Production Procedure of HuaroHot Rolled Steel Strip

The slab is the first production material of the rolling of hot rolled steel strip and the surface cleaning can be manually or by a scarfing machine with running the oxyacetylene torch. The treatment of the slab is pushed or walked over the wide side through a heating furnace with a dimension of 13 meters by 30 meters in diameter. These furnaces have the advantage of not creating cold streaks and slippage on the slab. As with flat and thick plates, the preheating temperature is approximately 1,250°C. After roughing, when needed for metallurgical reasons, it goes into the long (about 140 m) roll in front of the finishing mill for cooling. When the slab (at a speed of about 20 meters per minute) enters the finishing mill line, crop shear cuts off the head and tail, and high-pressure steam jets remove the secondary oxide coating formed during the rolling process. The strip is then rolled to a final thickness of 1.5 to 10 mm by six to seven high finishing mill stands.

Application of Hot Rolled Steel Strip

There are four ways for hot rolled steel strip according to product width and production process: hot strip rolling of wide strip steel, reversible hot rolling of wide strip steel, hot strip rolling of narrow strip steel and hot strip rolling with a planetary rolling mill. The strip steel is made of plain carbon steel, low alloy steel, stainless steel, and silicon steel. Hot rolled steel strip is mainly used for raw materials of cold rolled strip, welded pipe, cold-formed and welded steel or for making various components.

If you want to know more kinds of steel products, please visit our website.

在线联系供应商

Other supplier products

| Pickled Coils | Description of Pickled Coils Pickling is a production procedure to remove the oxide scale on the cold rolled steel coil surface during steelmaking.... | |

| Hot Briquetted Iron (HBI Iron) | Definition of HBI Plant Hot Briquetted Iron, known as HBI or HBI iron , is a premium form of Direct Reduced Iron (DRI).As a supplement for pig iron... | |

| Steel for Marine Use | General description of the best stainless steel for marine use Marine also is known as the shipbuilding industry, it's one of the biggest steel pr... | |

| Hot Rolled Steel Sheet | Hot Rolled Steel SheetProduction Process The production procedure of HRS is generally as follows: Iron making → steel making → continuous... | |

| Cold Rolled Coil | Description ofCold Rolled Coil Cold rolled coil, as known as CR coil, CRS or CRC. Cold rolled steel coils are a farther product that uses hot roll... |

Same products

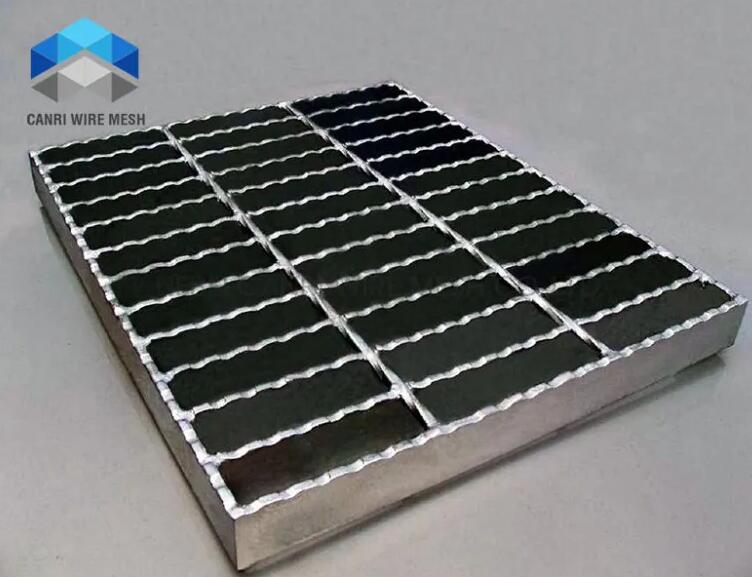

| Galvanized Steel Grating for Drainage | 卖方: Hebei Canri wire Mesh co.,Ltd | Galvanized Steel Grating for Drainage Steel gratingfor drainage, also known as galvanised draina... | |

| Floor Grating | 卖方: Hebei Canri wire Mesh co.,Ltd | Floor Grating Floor grating, also known as open grid flooringor bar grating, is a type of structu... | |

| Serrated Bar Steel Grating | 卖方: Hebei Canri wire Mesh co.,Ltd | Serrated Bar Steel Grating Steel bar gratinghas two surface type: serrated surface and smooth su... | |

| Stainless Steel Grating | 卖方: Hebei Canri wire Mesh co.,Ltd | Stainless Steel Grating Stainless steel gratinghas been the standard industrial foot walk produc... | |

| Galvanized Steel Grating | 卖方: Hebei Canri wire Mesh co.,Ltd | Galvanized Steel Grating Galvanized steel gratingis an ideal product for wet, slippery situation... |