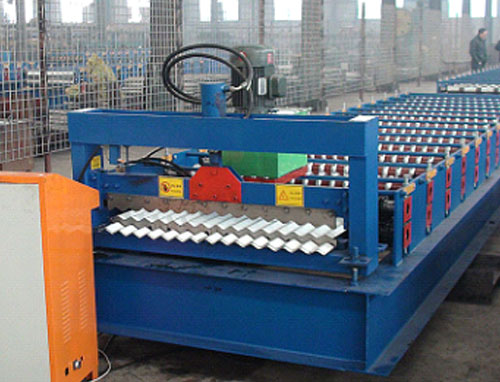

Roll Forming Machine

RollFormingMachineDesignTechnologyIntroduction

GENERALCONCEPTSofcoldrollformerlineprocessing:Roll-formingisaprocessinwhichthe

shapeofametalpanelisdevelopedbygraduallybendingthemetalthroughaseriesofroll

formingmachine,orpasses.Eachstandmustgeneratetheappropriateamountofdeformationforwhichitwasdesigned.In

general,thelevelodeformationateachstandisnotconstantduetoadjustmentsforspring

backandthepreservationofdimension.Sincethetoolingisdesignedto

controltheoutsidedimensionsoapanel,rollformersareusuallydesignedtooverworkthe

metalinspecificstands.Problemsintheformingsystemortoolingdesignmayexistifmaterials

havetobeoverworkedinthestands/toolingotherthanthosedesignedforoverwork.Therefore,

whenroll-formingproblemsoccur,itisimportanttoexamine

eachstageoftheprocessandnotmerelythestandatwhichtheprobleminitiallyappears.

Twobasictypesofroll-formingsystemsareutilized:aprecutlineand

apostcutline.Aprecutlineshearstheincomingmaterialtoaspecificlengthpriortoroll-

forming.Duringpostcutlineoperation,therollformedpanelrunscontinuouslyandis

shearedtotherequiredlengthafterroll-forming.

material:Oneoftheprincipalparametersthatdefinethesuccessofa

roll-formingoperationisthenatureofthematerial.Inorderto

designtheoptimalprocess,thetoolingdesignershouldbe

providedmaterialinformationtobeusedpriortothetooling

designing.Thisincludesmaterialmechanicalpropertyranges,gaugetolerancesandshape

tolerances.Inaddition,differentmetalliccoatings(hot-dipgalvanizedorGALVALUME1Coated

SheetSteel),organiccoatingsorpaintwillresultindifferencesinperformanceevenwith

thesamesetoftoolingduetotheirdifferentfrictionalcharacteristics.

在线联系供应商

Other supplier products

| XN24-210-840 roll forming machine roof plate | HebeiXinnuo24-210-840roofpanelformingmachine,thefeedingwidthis1000mm, adoptingrollformingmethod,canproducebeautifulappearance, strongpanelswhicha... | |

| roll forming machine 2 | Before the development of China's machine is not long,however,Thirty years of reform and development,the rapid development of Chinese enterprises,t... | |

| C35-C44 double deck roll forming machine | C35-C44doubledeckrollformingmachine HebeiXinnuodoublelayerrollformingmachineusesthenewestdoubledesign,onemachineproducttwoprofiles.ThisisC35-C44two... | |

| roof plate forming machine | Colorsteeltilesmachinesusethecolorcoatedsteelsheettoroll intoavarietyofwave-typepressureplatesthroughthecold-formed method.Itissuitableforindustria... | |

| C10-C21 double deck roll forming machine | HebeiXinnuodoublerollformingmachineusesthenewestdoubledesign,onemachineproducttwoprofiles.ThisisC10-C21twoprofiles,allpopularinRussia,Ukraine.Itco... |

Same products

| AEMK 588 Loader | 卖方: 烟台欣祥国际贸易有限公司 | 驾驶室高度:2670毫米 整车尺寸(长*宽*高):5700*2000*2670毫米 前轮配重:4250毫米 轴距:2500毫米 离地间隙:480毫米 最大卸料高度:3500毫米 最大... | |

| Quick Change Worktable | 卖方: Nextas Co.,Ltd | Quick Change Worktable Zero Point Pneumatic Chuck Zero Point Positioning Datum System NE... | |

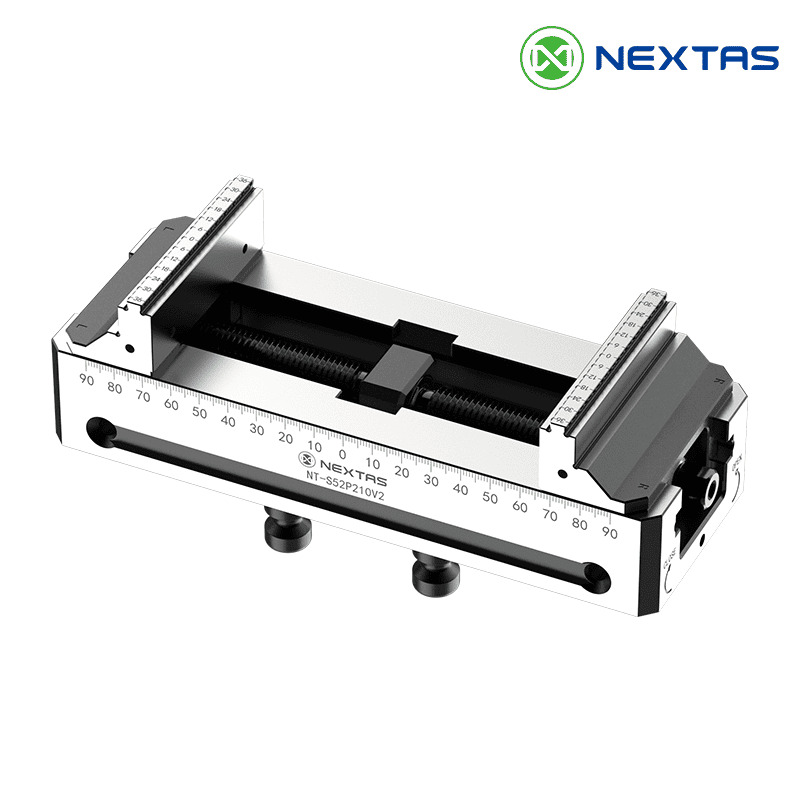

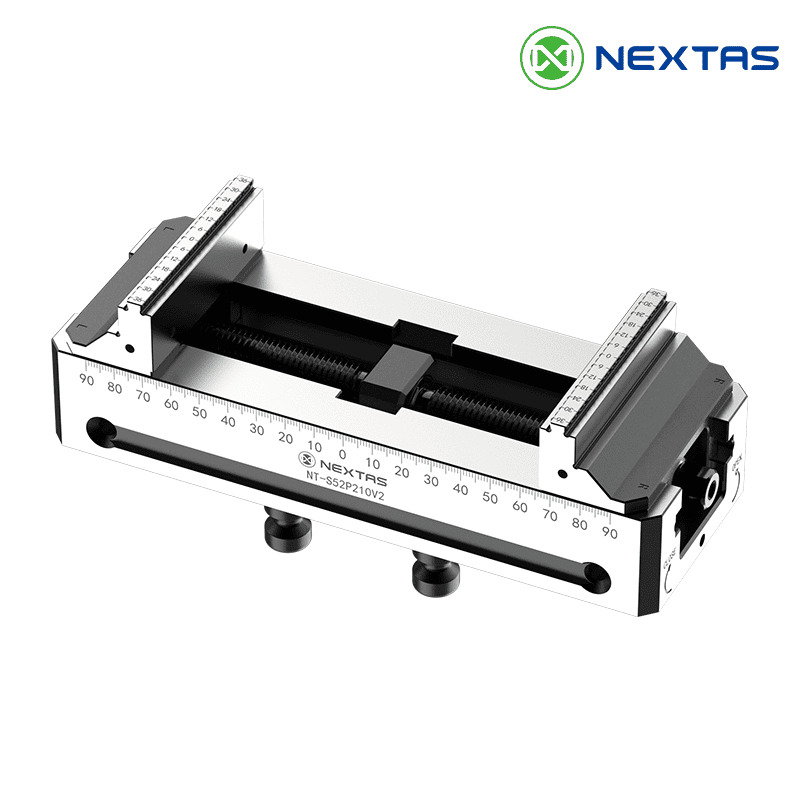

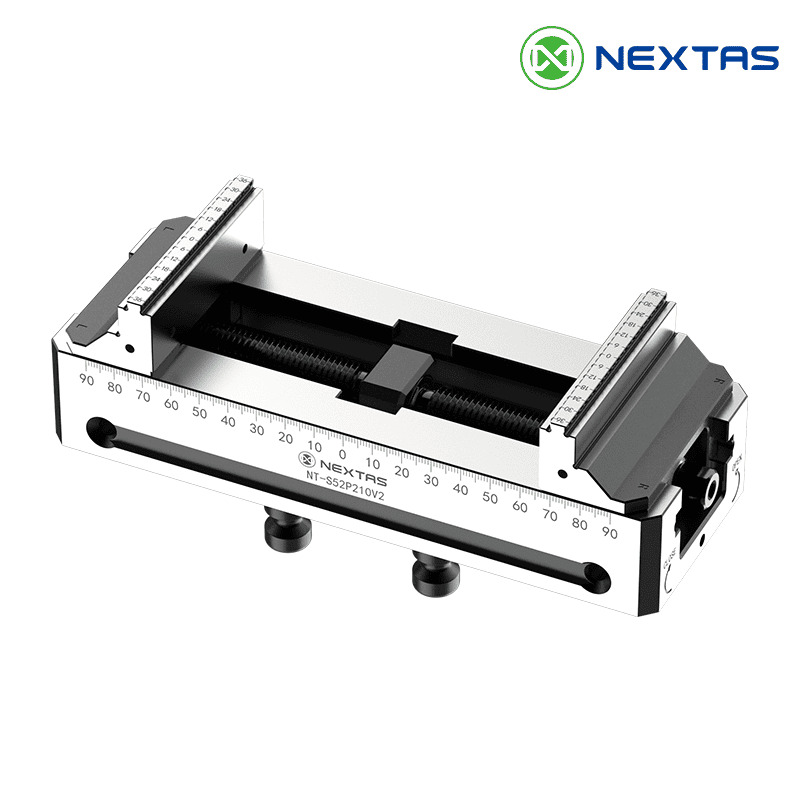

| Self Centering Vise | 卖方: Nextas Co.,Ltd | Self Centering Vise Key Advantages High precision: repeatability as tight as ≤ 0.005 mm ... | |

| BDS Positioning Chuck | 卖方: Nextas Co.,Ltd | BDS Positioning Chuck Self Centering Vise Self-centering vise is a type of workholding tool that... | |

| Quick Change Pallet System | 卖方: Nextas Co.,Ltd | Quick Change Pallet System Quick Change Pallet System Quick Change Pallet System delivers m... |