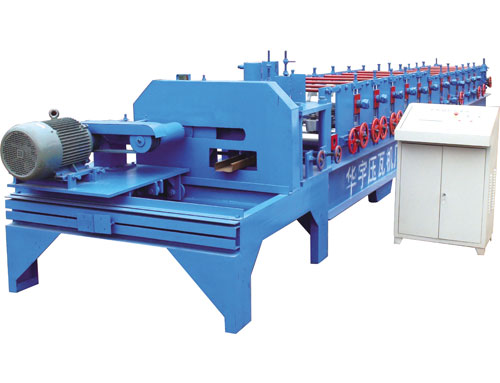

double deck roll forming machine

Themetaldeckformingtechnologyisoneofthemostadvancedmanufacturing

technologiesappearedinthelate80s.Theharshcompetitionfromthisindustryrequireda

shorterdesigningandmanufacturingperiodandalowerinvestmentriskatthesametime.This

machineemergesasthetimerequiresandthankstotheincreasinglyhigherstandards,thiskindof

technologyenjoysarapiddevelopspeed.

Themetaldoubledeckrollformingmachineis

drivenbythehydraulicpressureandinitiallytakeadvantageofthefrequencymodulation.

Thistechnologycanmakethemachinesuitableforproductsofdifferenttextureandshapethus

canimprovethecompactionoftheproductandshortentheformingcycle.Thiskindofmachine

canbeappliedintothemanufacturingprocessinthefollowingaspects:

1)Itcanalsobeusedintherapidmoldmanufacturingprocess.ThecombinationofRP

technologyandthetraditionalmoldmanufacturingtechnologywilldosomecontribution

toshortenthemolddevelopmentcycleaswellastoraisetheproductivity.Itisan

effectivewaytosolvetheweaklinkduringthemolddesigningandmanufacturingprocess.

Themetaldeckpedalshearingmachinespreadsabrand-newconceptofdesignandmanufacture.

Itenjoysarelativelylowcost,ahighermodifiabilityandauniqueprocess,thuscanprovideaperfect

waytopromotetheproducttothetargetmarketassoonaspossible.Allthesefactors

canmakethemetaldeckformingmachineoccupiesanimportantpositioninthe21stmanufacturing

industry.Besides,italsocanbeusedinthepackagedesignandmanufacturingprocessto

makethestandardization,generalizationandintellectualizationpossible.

2)Withinthisformingtechnology,aprototypecanbeproducedwithinonlyseveralhoursduring

theproductresearchanddevelopmentperiod.Sothecustomerscanusetheprototypetoevaluate

thedesignscheduleanddosomesimulationtestsaswellassomeassemblytests.Afterallthese

tests,feedbackswillbegiventothedesignerandsomeadjustmentswillbemadetoperfectthe

sampleproduction.Suchfeedbackactivitieswillnotbestoppeduntilasatisfiedresultcanbeachieved.

在线联系供应商

Other supplier products

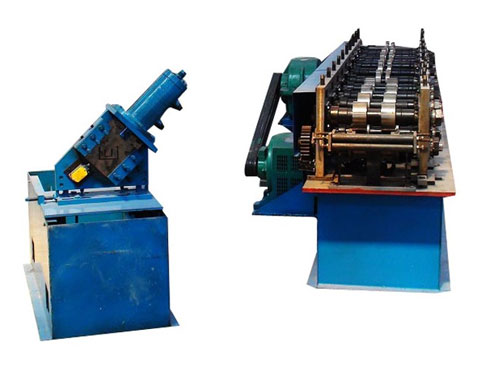

| roof plate forming machine | Colorsteeltilesmachinesusethecolorcoatedsteelsheettoroll intoavarietyofwave-typepressureplatesthroughthecold-formed method.Itissuitableforindustria... | |

| c purlin machine | Rollformingproductionlinecansetupmultipleprofilestocontinuousoperationofthepunch andcutparts.Forsomecuttinglength,thelinecanbesettousetheblankinthe... | |

| Roof plate forming machine | Roofplateformingmachinecomprisesamainmachineframe,Themainmachineframeisprovidedwithapowerdevice,abroachingplate,asheetmaterialblankingdeviceandavib... | |

| Light keel roll forming machine 2 | Light keel roll forming machineis used to produce different kinds of light keel products. Light keel products are a newly construction material, wi... | |

| Fast changeable C purlin machine | ThisCpurlinmachineisfastchangeabletype.Itneednotchangethecuttingmouldandneednotadjustthespacerbush.Changingthesize,isfullautomatic.Thisisthenewtyp... |

Same products

| AEMK 588 Loader | 卖方: 烟台欣祥国际贸易有限公司 | 驾驶室高度:2670毫米 整车尺寸(长*宽*高):5700*2000*2670毫米 前轮配重:4250毫米 轴距:2500毫米 离地间隙:480毫米 最大卸料高度:3500毫米 最大... | |

| Quick Change Worktable | 卖方: Nextas Co.,Ltd | Quick Change Worktable Zero Point Pneumatic Chuck Zero Point Positioning Datum System NE... | |

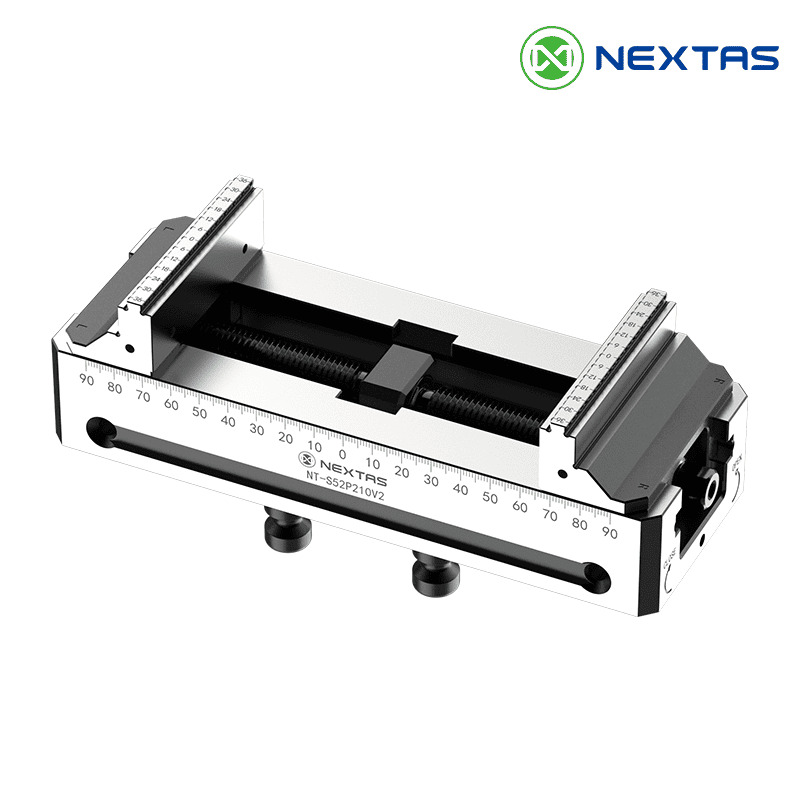

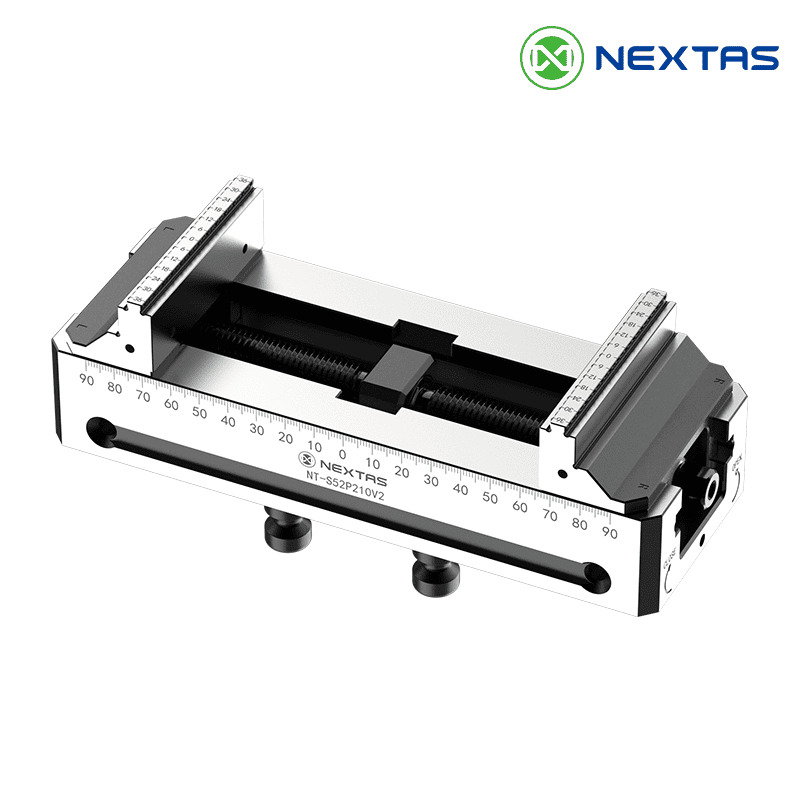

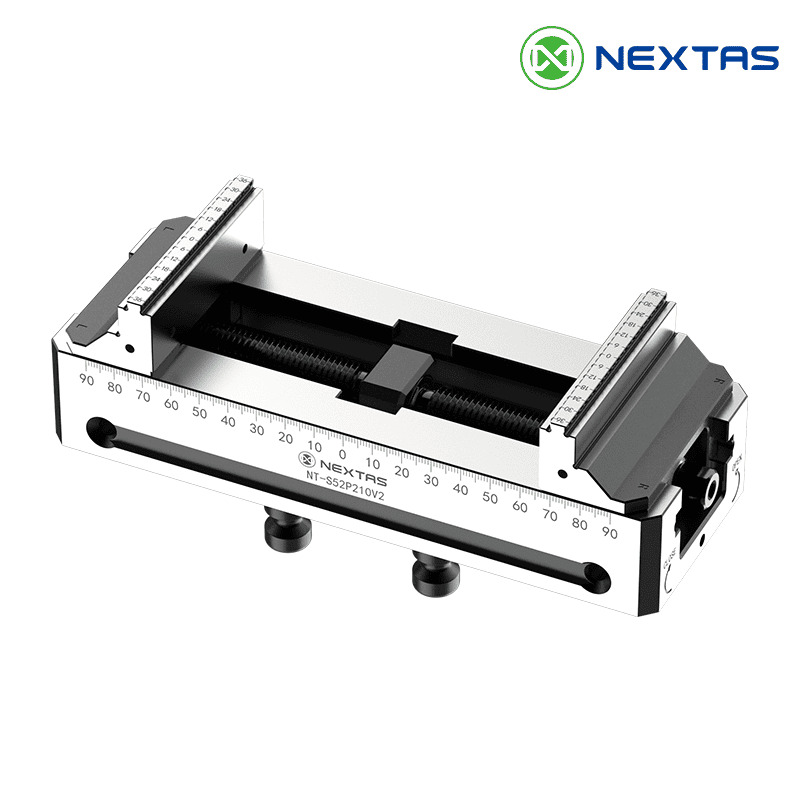

| Self Centering Vise | 卖方: Nextas Co.,Ltd | Self Centering Vise Key Advantages High precision: repeatability as tight as ≤ 0.005 mm ... | |

| BDS Positioning Chuck | 卖方: Nextas Co.,Ltd | BDS Positioning Chuck Self Centering Vise Self-centering vise is a type of workholding tool that... | |

| Quick Change Pallet System | 卖方: Nextas Co.,Ltd | Quick Change Pallet System Quick Change Pallet System Quick Change Pallet System delivers m... |