How to Optimize the Plates of Jaw Crushing Machine?

As we all know, the operation of jaw crushing machine is mainly driven by the mutual work of movable jaw plates and static jaw plates. As one of the most important part for China jaw crusher, the movable jaw plate is also one of the relatively heavy part. The design of movable jaw plate is directly related with the crushing effect of jaw crushing plant. As a professional, FTM Crusher Company has done a lot of efforts to improve the performance and technological level of jaw crusher machine.

While, the key factor for these efforts is to optimize the design of jaw plates. Then, how to optimize the design of jaw plates? The following content will give you answers. At present, most jaw crushers on the market are relatively heavy in volume. While, the movable jaw plates are relatively heavy in the whole China jaw crusher. Therefore, if the strength is enough, efforts on reducing the weight of movable jaw plate are the technological breakthroughs of design optimization.

In order to satisfy the stress condition and reduce the weight on movable jaw plate,has changed the rectangular reinforcing rib into the trapezoid reinforcing rib. Since technological processes like welding and forging can influence the performance and quality of jaw plates and whole jaw crushing plant, FTM thinks that it is necessary to improve the welding and forging technologies. If you want to know more about the jaw crushing plant, please feel free to visit our website and leave messages our it or directly us. We will give you a professional configuration and quotation.

Fote Heavy Machinery:

Fote Official Email:

在线联系供应商

Other supplier products

供应产品

Working Principle of FTM Impact Crushing Machine

Among all crushers, impact crusher and cone crusher are mainly used for the secondary and tertiary crushing. While, in aspects of crushing principl...

Filter Devices Equipped for Fote Coal Slime Dryer

During the working process of coal slime dryer, dust is easy to be produced if materials to be dried are in briquettes, pellets or balls. What&rsqu...

Ways for the Power Saving of Coal Briquette Machine

Along with the rapid economic development, demands for thecoal briquette press machineare becoming more and more great. Coal briquette press machin...

Maintenance Work for Saw Dust Pellet Machine

Maintenance work for saw dust pellet machine is very important, since it can increase the output of pellets and prolong service life of key parts. ...

Ways to Make Coal Briquette Plant More Efficient

Coal briquette plant, also named as coal briquetting plant, is mainly used to process the coal wastes into briquettes of great value.To improve the...

Same products

AEMK 588 Loader

卖方: 烟台欣祥国际贸易有限公司

驾驶室高度:2670毫米 整车尺寸(长*宽*高):5700*2000*2670毫米 前轮配重:4250毫米 轴距:2500毫米 离地间隙:480毫米 最大卸料高度:3500毫米 最大...

Quick Change Worktable

卖方: Nextas Co.,Ltd

Quick Change Worktable

Zero Point Pneumatic Chuck

Zero Point Positioning Datum System

NE...

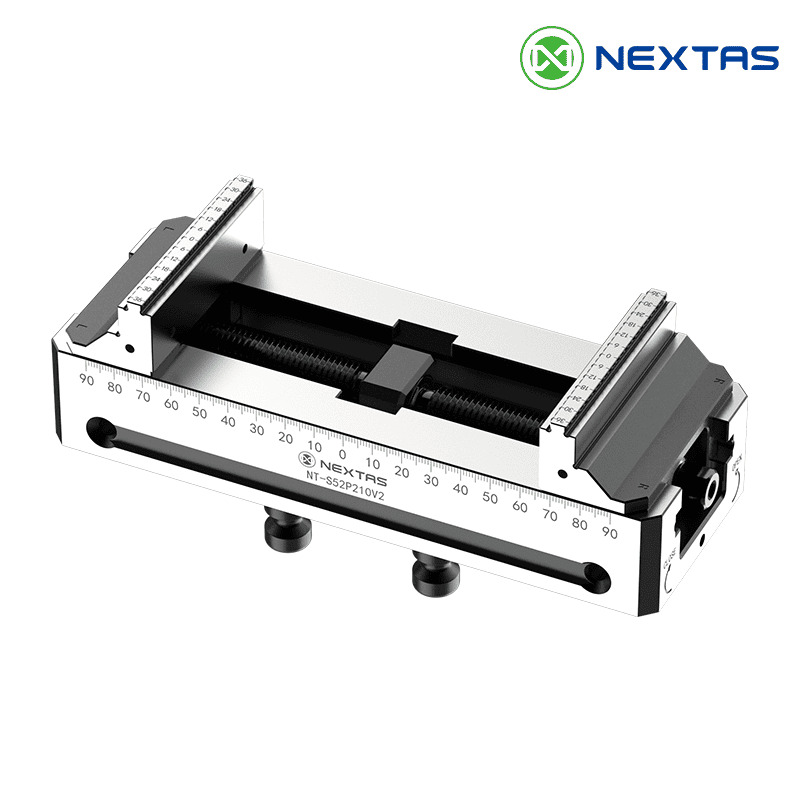

Self Centering Vise

卖方: Nextas Co.,Ltd

Self Centering Vise

Key Advantages

High precision: repeatability as tight as ≤ 0.005 mm ...

BDS Positioning Chuck

卖方: Nextas Co.,Ltd

BDS Positioning Chuck Self Centering Vise Self-centering vise is a type of workholding tool that...

Quick Change Pallet System

卖方: Nextas Co.,Ltd

Quick Change Pallet System

Quick Change Pallet System

Quick Change Pallet System delivers m...