Heavy Copper PCB, Heavy Copper PCB Manufacturer

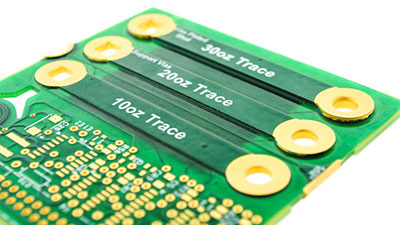

Heavy Copper PCB, Heavy Copper PCB ManufacturerHeavy Copper PCBs are printed circuit boards with 3 or more ounces of finished copper in the inner and/or outer layers.Heavy Copper PCB General InfoHeavy Copper Board does not have a

set of definition per IPC. According to PCB industry, however, peopel

generally use this name to identify a printed circuit board with copper

conductors 3 oz/ft2 - 10 oz/ft2 in inner and/or outer layers. And

Extreme heavy copper PCB refers to 20 oz/ft2 to 200 oz/ft2 printed

circuit board.Heavy copper normally used for a

various products but not limited to: high power distribution, heat

dissipation, planar transformers, power convertors, and so on.Design Guide for Heavy Copper PCB The minimum width and

thickness of a heavy copper PCB conductor is determined primarily on the

basis of the current carrying capacity required and the maximum

permissible conductor temperature rise. A circuit board trace, depending on

its size and manufacturing process, may not be rectangular in shape.

Heavy copper conductors can significantly add to the overall board

thickness.Additive (plating) processed are preferred to subtractive (etching) processes but are more expensive). Typical conductor width/spacing/thickness tolerance is +/-20%, although tighter tolerance is achievableCapability of Heavy Copper PCB

Base material: FR4/AluminumCopper thickness: 4 OZ~10 OZExtreme Heavy Copper: 20~200 OZOutline: Routing, punching, V-CutSoldermask: Wite/Black/Blue/Green/Red OilSurface finishing: Immersion Gold, HASL, OSPMax Panel size: 580*480mm(22.8"*18.9")Benefits of Heavy Copper PCBsElimination of complex wired buss configurationsIncreased current carrying capacityIncreased endurance to thermal strainsOptimized use of exotic high temperature materials with lower probability of circuit failureAbility to incorporate multiple copper weights on the same layer of circuitry (layer count reduction)Added copper plating in the heat vias (thermal resistance reduction)Selective areas plated with heavy copper can function as a heat sink or interface to cold plate (built-in heat sinks)Integration of high-current circuits and control circuits on a single PCBPlease contact us for more information about heavy copper PCB and extreme heavy copper printed circuit board (heavy copper PCB).

Other supplier products

|

|

|

Medical Printed Circuit Board Solutions for Life Science Applications MOKO offers small, mid, and full-level manufacturing solutions

for medical ... |

|

|

|

Best Flexible LED PCB, Flexible LED PCB Boards from MOKOOur business has effectively expanded its business in the market owing to the presented ele... |

|

|

|

Moko Technology Ltd is one of the leading China multilayer pcb manufacture high quality professional oem pcb manufacturers and suppliers with profe... |

|

|

|

MOKO specializes in the assembly and production of printed circuit boards (PCBs) for Industrial companies of all sizes.For several years MOKO has w... |

|

|

|

Moko Technology Ltd is one of the leading China enig finishing pcb,printed circuit board design and clone service available manufacturers and suppl... |

供应产品

Same products