Adapter Charger Housing Mold 496-1

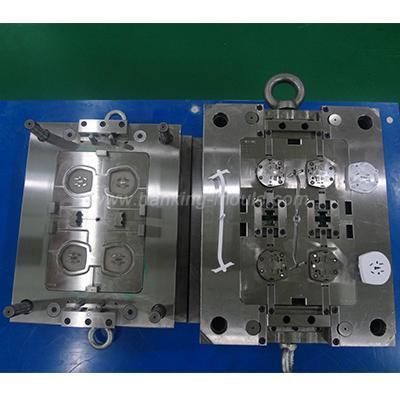

Mould Name: Adapter Charger Housing Mould

Part Material: PC

Product Size: 58.3*57.9*8.6mm

Product Description: Adapter Charger Housing UK

Mould Cavity: 4 Cavities

Mould Size: 400*450*343MM

Suitable Injection Machine: 160 ton

Mould Cavity Steel: ASSAB8407

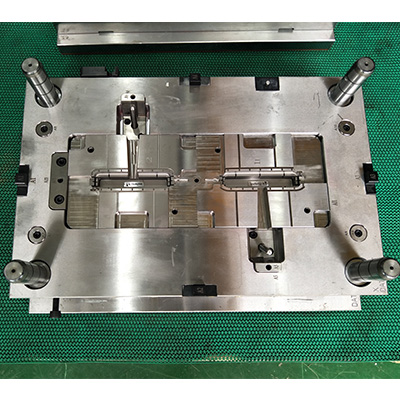

Mould Injection System: Cold runner w/ tunnel gate

Mould Ejection System: Ejector Pin

Mould Cycle Time: 26's

Mould Life Cycle: 500,000

Lead Time: 60 days

Mould Features: 8 Sliders

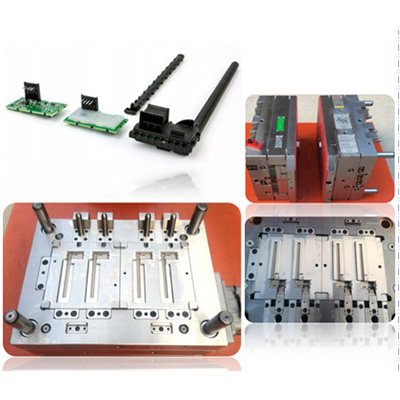

Adapter mold is also AC charger mold, HanKing has made a lot of such moulds. For the adapter mold or AC charger mould, the appearance is important as well as the part dimension.

What issues should be noted in the tooling design?

First, we should choose the parting line of the part, parting line in cavity side, and parting line in the core side and it's very important to get customers' approval for the parting line.

The mold designer must choose the appropriate gate position and diameter of the gate according to the structure of the product and the requirements of the clients. For this charger mould, we normally suggest using point gate.

How to release the plastic adapter from the mould also requires careful consideration by the designer. Designers must carefully study the structure of the product, using sliders, lifters and ejection mechanisms to help the product smoothly get out of the mold cavity.

Manufacturing tips: shut-off angle along the slider moving direction as well as polishing the steel along the direction of product removal.

When some areas make the mould ejection out difficulty, find out the solution and send a proposal to the customer.

Try to make insert in the complicate area and to confirm the split line of insert pin with customers.

Reasonable use of ejector pin, ejector sleeve, ejector blade, etc. mechanisms, the distribution of the ejector pin should be even and balance.

The texture and polish are different in the cavity and core of the mould.

Most of the time, the plastic part drawing from the customer is not designed with a draft angle, we should propose to increase the draft angle within the allowable range.

It should be recessed on the bottom surface to avoid sink mark because of the wall thickness of the pillars.

The designer should check if any ribs or holes are not able to put ejector pin.

Sharp steel is must be avoided.

As the ac mould engineering limited, HanKing Mould has excellent experience in Adapter Charger Mould, we made Adapter Mould for different country standard, good water cooling to get the beautiful part surface, and automatic ejection.

Following the concept of customer first, hanking molddedicates to be a trustworthy tooling company by designing and manufacturing plastic injection molds, providing custom plastic molding manufacturing and services according to every individual's requirements. Hanking's successes are ensured by our management capability, technical knowledge, advanced plastic tooling equipment and professional injection molding services. We are pursuing better quality and technical capability to meet the demands of increasing mold making markets.

We are a responsible china plastic injection mold makerand chinese injection molding companiesand have experience in supplying custom plastic injection molding service for many years. Our production sites have been accredited the certification of TS16949, ISO 14001 and ISO 9001, etc. You can fully trust our production sites, products and place your orders.

在线联系供应商

Other supplier products

| Prototype Mould | Soft Prototype Mold Prototype moldis a kind of test mould before mass production mould, customer make test mould for design verification, Product ... | |

| Automotive Mold | Automotive Molds Professional Automotive Injection Mold for Cartridge Fuses TolerancesPlates and Mold Base Components:± 0.013 mm (± ... | |

| Insert Molding | Plug Mold Mould Name: Plastic Injection Wall Plug Mold Part Material:PBT GF15 Product Size: Product Description: Plug CH versionMould Cavity: 4 Cav... | |

| Mold Trial | Plastic Mould Trialof Hankingtec In hanking mould’s trial shop, HanKing Mould Enginering Ltd.has7 injection molding machines with a clamping... | |

| Electronic Molding Parts | HanKing Mould Enginering Ltd. started the business in the year of 1996 as one of the chinese plastic injection molding companiesin the line of mold... |

Same products

| AIT500-SG High-Precision Current Sensor Transducer | 卖方: Shenzhen Hangzhi Precision Electronics Co., Ltd | AIT500-SG 凭借其在现有直流传感器技术基础上应用的多点零磁通技术系统和高频纹波传感通道,在全带宽范围内实现了高增益和高测量精度。 多点零磁通技术系统通过结合激励磁通闭环控制、自激励磁通... | |

| JWA2-M Oil Micro Moisture Sensor | 卖方: Shenzhen Joinwe Smart Co.,Ltd | JWA2-M micro moisture sensorcan quickly and accurately detect oil water activity (moisture satura... | |

| Made in China Displacement sensor 4000TDG for thermal power plant | 卖方: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Made in China Displacement sensor 4000TDG for thermal power plant YOYIK professional production ... | |

| China made Control System LVDT 5000TDGN for power plant | 卖方: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "China made Control System LVDT 5000TDGN for power plant Dongfang Yoyik has advanced technology a... | |

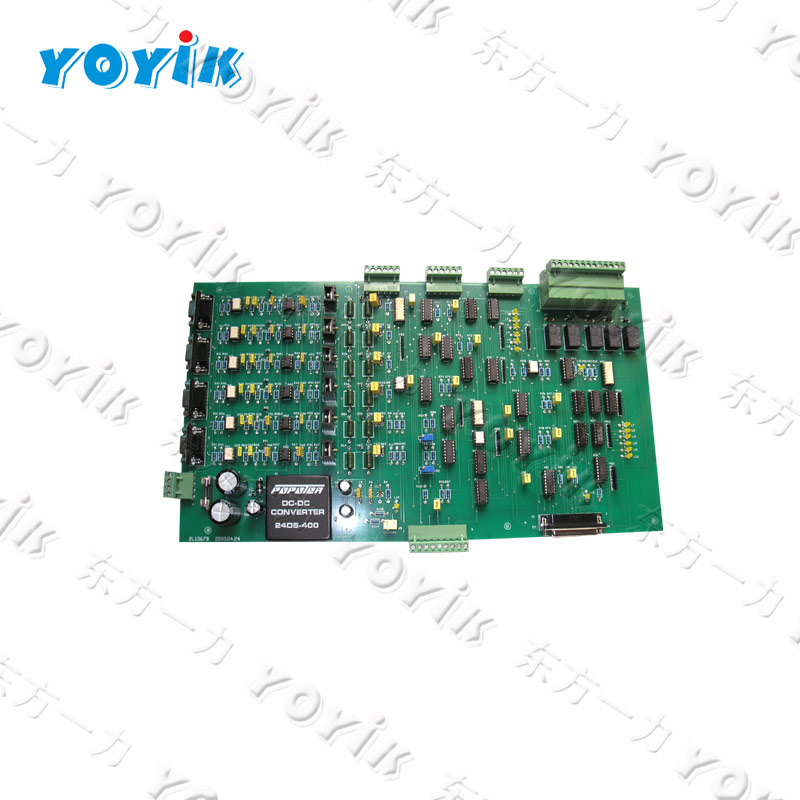

| China supplier main control board APF7.820.117A-A power plant spare parts | 卖方: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "China supplier main control board APF7.820.117A-A power plant spare parts Dongfang Yoyik is spec... |