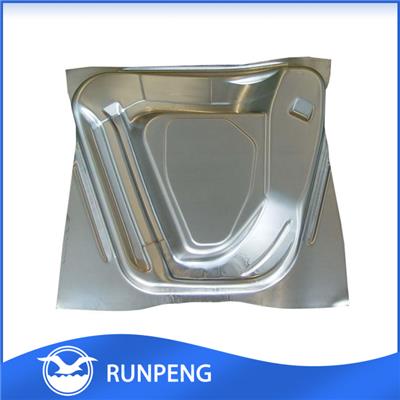

Stainless Steel Stamping Motor Part

Product Description Product nameStainless steel stamping motor partProcess MethodStampingMaterial:Stainless steelFinishNaturalColorBrightDimension500x450x60mmShapeOblongProduction ProcessStamping,Website:, deburring , Drill&tapping, full inspection and packing.ApplicationMotorCustomizeOEMTooling lead time15 working daysMass production lead time25 working daysMOQ/batch500pcsPackingSeparate Packing, 10 pcs/carton, 30 cartons/palletTooling payment term50% in advance, balance after send the successful samplesMass order payment term30% deposit, 70% T/T before shipmentPrice termEXW, FOB, CIFFOB portShenzhen or HongkongPlace of originGuangdong, China.CertificationISO9001:2008Production Process Product PictureMore InformationAvailable Stamping MaterialAluminum, Steel, Stainless steel, CRS, Galvanized sheetAvailable Surface TreatmentPainting, anodize, zinc platedSoftwarePro/E,UG, Solidwork, Auto CAD, PDFAdvantages1.Own factory2.We can provide competitive price.3.High precision, tolerance can be within ±0.05mm.4.We can also provide one-stop service,including mould making, stamping, CNC machining, surface treatment and assembly.5. With individual working instruction6.100% inspection before shipment.Confidential service1.Your information is confidential.2.Your drawings are confidential.3.Your moulds are only for you.Guarantee2 yearsQuality Control Management ItemQuestionAnswer1.1Is there quality control on all production lines?Yes, all production lines have adequate quality control.1.2Do the QA/QC inspectors work independently from the production line?Yes1.3Who does the QC/QA Manager / Supervisor report to?Yes1.4How many QA/QC inspectors in total?Yes1.5Does the company prepare all of the necessary working instruction and inspection instruction before the mass production start?Yes1.6Does the Working instruction contain all of the requirements from customer?Yes1.7Does the worker been trained by the working instruction?YesAfter Sales Service ItemQuestionAnswer1.1Is customer feedback including complaints, clearly recorded and maintained?Yes, with a standard feedback form and records.1.2Are there any clear procedures for handling customer complaints?Yes, with clear procedures and written records1.3Is there a closed-loop corrective action system in place?Yes1.4Can finished/packaged products be traced by lot identification to the appropriate raw material test reports?Yes, with procedures to trace raw materials.

Other supplier products

|

|

|

Product Description Product nameAluminum Die casting CCTV Security Camera Dome CaseProcess MethodDie castingMaterial:Aluminum Alloy A380FinishPowde... |

|

|

|

Product Description Product namealuminum stamping electronic enclosureProcess MethodStampingMaterial:AluminumFinishAnodizeColorNaturalDimension350x... |

|

|

|

Product Description Product nameAluminum Die Casting LED Street Light HousingProcess MethodDie castingMaterial:Aluminum Alloy ADC12FinishPowder Coa... |

|

|

|

Product Description Product nameAluminum Die Casting LED Lamp HousingProcess MethodDie castingMaterial:Aluminum AlloyFinishPowder CoatingColorBlack... |

|

|

|

Product Description Product nameCustomized injection PC plastics moulding productsProcess MethodinjectionMaterialPCFinishNaturalColorWhiteDimension... |

供应产品

Same products