Flatbed Ironing Tester

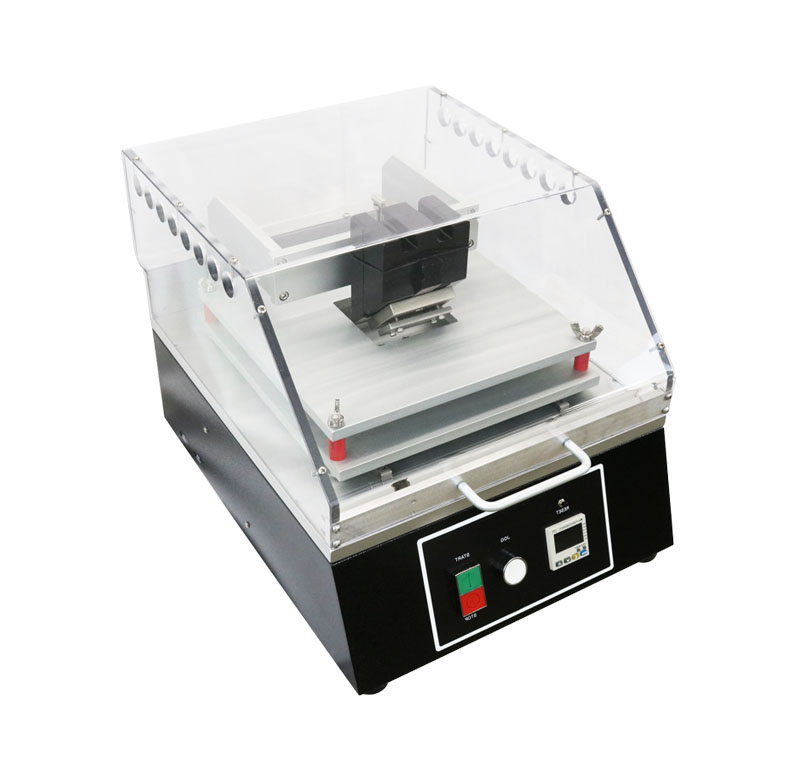

The Flatbed Ironing Tester is a laboratory-grade instrument designed to simulate real-world ironing conditions for evaluating fabric thermal performance. It provides precise assessment of crease recovery, heat resistance, dimensional stability, shrinkage behavior, and surface appearance changes. Ideal for quality control, production inspection, and textile R&D, it delivers consistent, repeatable, and standard-compliant test results.

Application

Suitable for a wide range of textile and material evaluations, including:

Apparel fabrics (cotton, polyester, wool, nylon, spandex, blends)

Home textiles (bedding, upholstery, curtains, table linens)

Industrial fabrics (automotive interiors, filtration materials, protective garments)

Functional textiles (FR fabrics, coated fabrics, waterproof/breathable laminates)

Laminated materials (PU/PVC synthetic leather, soft-touch coatings, printed laminates)

Finished fabrics requiring wrinkle-resistant, shrink-resistant, or heat-set performance

Smart and sensitive textiles requiring controlled thermal tests

QC laboratories, inspection institutes, textile mills, and educational institutions

Forensic analysis of heat-damaged textiles and garment care research

Features

(1) Realistic ironing simulation – Accurately reproduces domestic and industrial ironing conditions.

(2) Multi-function testing – Supports crease recovery, shrinkage, and heat-setting evaluations.

(3) Touchscreen control – 7-inch display with programmable test sequences.

(4) Stable & repeatable performance – Uniform heating and reliable pressure control.

(5) Built-in data logging – Test parameters can be exported for documentation.

(6) Enhanced safety system – Overheat protection and interlock safety switch.

(7) Low-maintenance design – Easy-clean platform and durable heating system.

Parameters

| Parameter | Specification |

|---|---|

| Temperature Range | Ambient +20 °C to 300 °C |

| Heating Rate | 10 °C/min (programmable) |

| Temperature Uniformity | ±2 °C across test area |

| Pressure Control | 0.5–5 kPa adjustable |

| Test Area | 300 × 300 mm heated flatbed |

| Cooling System | Forced-air cooling (30 °C recovery in 5 min) |

| Power Supply | 220 V / 50 Hz, 1.5 kW |

| Dimensions | 600 × 500 × 1200 mm (W×D×H) |

| Weight | 45 kg |

| Control System | 7-inch touchscreen with programmable sequences |

在线联系供应商

Other supplier products

| Motorized Notching Machine | Plastic electric notch prototype is a cantilever beam, simply supported beam impact testing machine to do the impact toughness test of non-metallic... | |

| Gravel Resistant Impact Tester | The Gravel Resistant Impact Tester/Stone Chip Tester is specifically designed for gravel impact testing of automotive materials and surface coating... | |

| Electronic single fiber strength meter - Test Equipment | Compliance Standards - GB/T14337 - GB/T9997 - GB/T13835.5 - GB/T21120 - ISO5079 - ISO11566 - ASTM D3822 - BS4029 Application Scope - Used... | |

| Universal Wear Tester(UWT)/Stoll Quartermaster | Application Universal Wear Tester (UWT) is used to determines the wear and abrasion resistance of fabric used in clothing, footwear and industrial... | |

| Wire Torsion and Winding Tester | The Wire Torsion and Winding Tester is a versatile instrument designed to perform both torsion and winding tests on metal wires. It evaluates the m... |

Same products

| Air Intake Filter Test System | 卖方: Standard Groups | The Air Intake Filter Test System is designed for testing industrial air filters and engine air f... | |

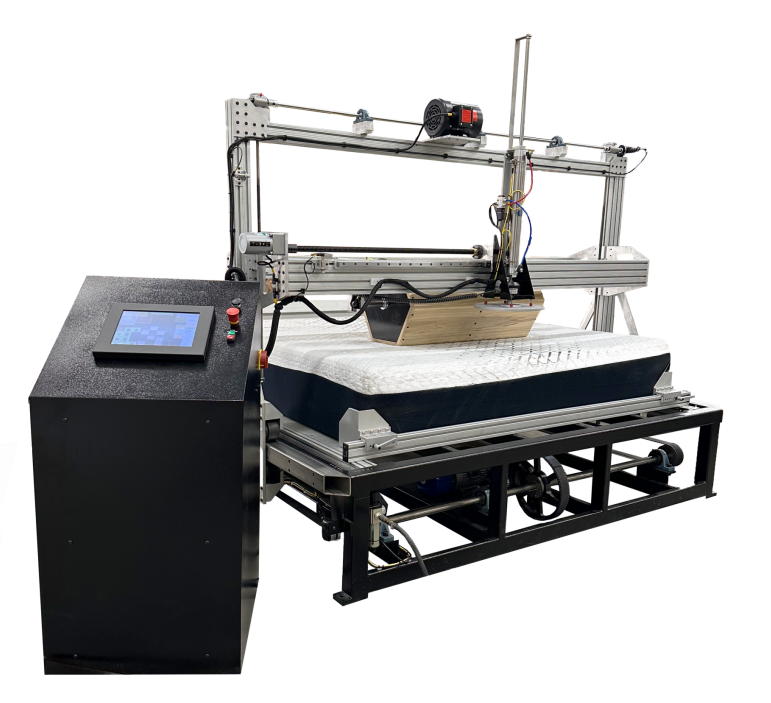

| Mattress Spring Fatigue Tester,ASTM D3574 ,how to test mattress for sagging | 卖方: Standard International Group (HK) Limited | The King Size Foam Fatigue Tester is a single-station pneumatic fatigue testing system designed f... | |

| Mattress Rollator,ASTM F1566 ,Mattress Durability Tester,Mattress Fatigue Tester | 卖方: Standard International Group (HK) Limited | The Mattress Rollator is a laboratory durability testing system designed to evaluate the long-ter... | |

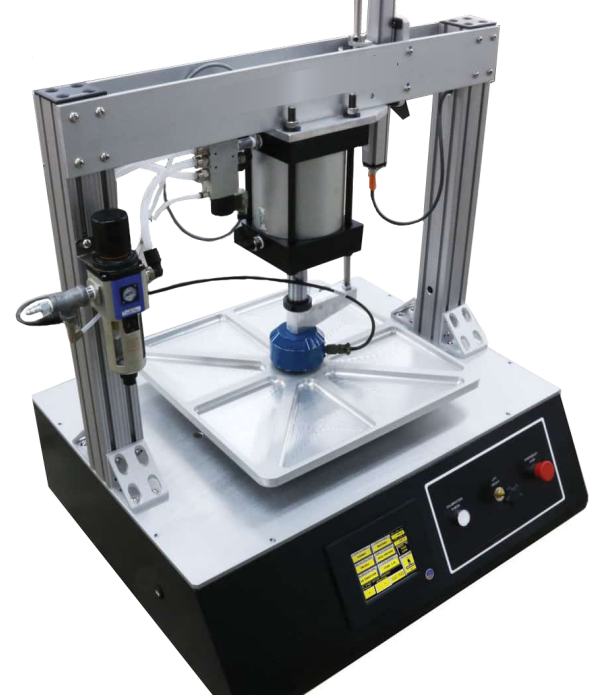

| HD2 Pneumatic Foam Fatigue Tester,ISO 3385,Foam Fatigue Testing Machine | 卖方: Standard International Group (HK) Limited | The HD2 Pneumatic Foam Fatigue Tester is a heavy-duty, single-station laboratory testing machine ... | |

| VW Heel Abrasion Tester,ISO 4649 ,Heel Performance Testing Machine | 卖方: Standard International Group (HK) Limited | The VW Heel Abrasion Tester is designed to evaluate the wear resistance of floor covering materia... |