Stainless Steel Screw Conveyor

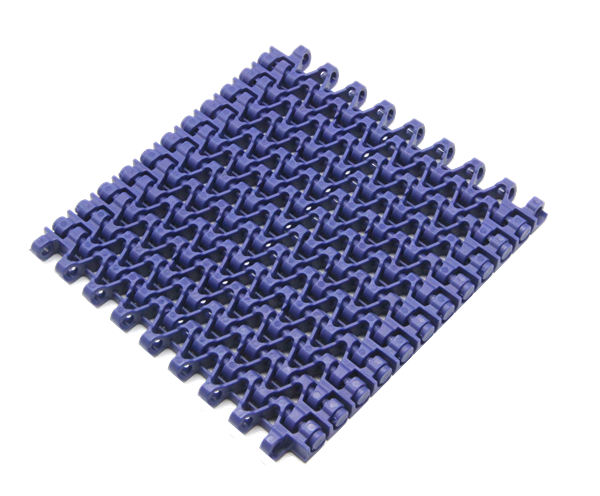

Stainless steel screw conveyor is divided into two types: horizontal screw conveyor and vertical screw conveyor. It is mainly used for the horizontal conveying and vertical lifting of various powdery, granular and small bulk materials. It is not suitable for this machine. Conveyor is easy to degenerate, sticky, easy to agglomerate or special materials with high temperature, pressure, and corrosivity. In principle, different types of screw conveyors can be made of stainless steel, collectively referred to as stainless steel screw conveyoror stainless steel auger. Types of stainless steel screw conveyors can be divided into LSY screw conveyors (tube type), LS screw conveyors (U type), GX screw conveyors (U type), LC vertical screw conveyors and WLS non-shaft screw conveyors, Structure type and design parameters can refer to the introduction page of other screw conveyors.

Stainless steel screw conveyor has a compact structure, small cross-sectional area, light weight, good sealing performance, high transmission efficiency, flexible process layout, installation, disassembly, easy movement, safe operation. It is not easy to produce corrosion, pitting, corrosion or wear. There are two forms of horizontal or inclined delivery. There is a discharge valve at the lower end of the feed inlet, and the screw can be reversed, so the discharge and cleaning are very convenient. Stainless steel screw conveyor mainly has the advantages of acid resistance, alkali resistance, high temperature resistance or low temperature resistance, wear resistance, not easy to rust, and not easy to contaminate materials. Its material can be 304, 316L, 321, or some special occasions use titanium steel and other materials. According to different fields of use choose the right stainless steel material.

Can meet a variety of material transport requirements, such as dry powder, wet powder, high temperature materials (temperature up to 200 °C) corrosion requirements, sealing requirements and so on. Spiral conveyor features: Based on the domestic and foreign advanced spiral conveyor manufacturing technology, its overall rigidity is good, smooth operation, easy centering, reliable sealing, screw shaft of stainless steel shaft screw machine generally adopts both ends of the roller bearing support (The rolling bearing adopts domestic and foreign high-quality products, long running cycle, convenient loading and unloading), and the intermediate suspension can be set for special requirements. The material of the shaft and the bearing in the suspension part is high wear-resistant and corrosion-resistant alloy material. A year or more; for high temperature materials, the device has a thermal compensation function. There are two types of direct drive and chain drive in the drive.

When the stainless steel screw conveyor is working, the rotating spiral vane conveys the material to be conveyed, so that the force that the material does not rotate together with the spiral elevator vane is the material's own weight and the friction resistance of the spiral elevator casing to the material. The screw shaft of the spiral elevator is welded with the spiral blade. The surface of the blade has different solid surface type, belt surface type and blade surface type according to the different materials. The screw shaft of the spiral elevator has a thrust bearing at the end of the material movement direction. When the spiral tube is long, the middle suspension bearing should be added.

Stainless steel screw conveyor is widely used in various industries, such as food, spices, pesticides, veterinary drugs, building materials, chemicals, electricity, metallurgy, coal, carbon, food and other industries, suitable for horizontal or inclined conveying powder, granular and small pieces of material Such as food, seasoning foods, pesticides, feed, coal, ash, slag, cement, grain, chemical, pharmaceutical, food, or environmental protection projects in some areas such as sewage sludge treatment equipment. Screw machines are not suitable for conveying highly viscous, highly viscous, easily agglomerated materials.

Hebei Ou Tai Environmental Protection Equipment Co., Ltd. is aprofessional stainless steel screw conveyors manufacturers. We provide Dust Collector, Dust Conveying System, industrial dust collection systemsand so on. Want to know more? Please contact us.

在线联系供应商

Other supplier products

| Electrostatic Dust Collector | Electrostatic Dust Collector The working principle of the electrostatic dust filteris to use the high voltage electric field to ionize the flue gas... | |

| Anti-Static Polyester Needle Felt Bag | Anti static filter bagis currently ideal dust filter material, with good ventilation energy, high dust removal efficiency, and a certain degree of ... | |

| PPC Air Box Pulse Bag Filter | PPC type airbag pulse bag filter is a new product introduced by the American Fule Company. This type of dust remover can be widely used in glass in... | |

| DMF-Z Right Angle Electromagnetic Pulse Valve | DMF-Z Right Angle Electromagnetic Pulse ValveProduct introduction: The electromagnetic pulse valve is imported from abroad (also known as the diaph... | |

| Dust Collector Accessories | Dust collector accessories kitinclude cloth bag for bag filter, skeleton (bag cage), electromagnetic pulse valve, pulse controller, star-type unloa... |