High Frequency Dryer For Insulation Cardboard 2019

It is an advanced process method to dry and mold the insulated board with the high-frequency electric field.

This production method has many obvious advantages compared with the traditional steam, electric drying, and hot air processing methods.

The high-frequency drying equipment developed by our company for high voltage transformer's cardboard insulationis advanced in technology and perfect in function. For many years, it has been applied to a large number of large enterprises at home and abroad. All well received by users both at home and abroad.

Unlike traditional heating, high-frequency heating uses the strong penetration ability of high-frequency electric field (high-frequency electric field penetrability is far stronger than microwave), which makes the material molecules repeatedly polarized, resulting in severe friction and self-heating from inside to outside. It does not require any preheating and heat conduction, so its heating efficiency is very high.

In addition, high-frequency heating is superior to traditional drying and microwave drying, that is, the electric field can realize selective heating through the mould, concentrate energy on the location where heat is needed, and further avoid unnecessary consumption.

Therefore, it can not only greatly save energy, but also greatly shorten the heating time and improve the production efficiency.

Angle ring heating time usually chord length 550mm and thickness 2.5-3mm of not more than 6 minutes, chord 700mm angle ring heating time is 8 minutes. If the multi-layer material is dried together at the same time, the cost will be reduced more.

Because in the heating process, the material of the water evaporated quickly, and the heat dissipation condition is better than the inner surface, the inner temperature will be slightly higher than the outer layer, according to the material drying theory: with heating process, maintain steam pressure and heat transfer in the same direction is most conducive to the drying of materials.

This heating method not only makes the internal fast and thorough but also completely avoids the phenomenon of the external coke.

Because of the high-frequency electric field heating both inside and outside, it is more suitable for the insulation material or multi-layer material to be heated at the same time.

When the material is heated in the high-frequency electric field, the equipment will put pressure on the mold, so that the material in the water was a lot of extrusion and molding in the electric heating at the same time.

In this process, if the material itself contains impurities like metal powder with low insulating, impurity will produce high temperature overheating and even breakdown insulating board in the high-frequency electrical field. At this time the equipment will warn alert,and start the protection system so that the disqualified material is eliminated during the heating process.

Ensure the quality of the product so that it is suitable for higher insulation requirements.

This high-frequency drying equipment does not require any auxiliary equipment. After electrifying and material loading, the whole drying process can be completed by pressing a button. The operation is very simple.

There is no pollution to the environment. Without any dust, smoke or high temperature.

The national high-frequency electric field leakage standard: 25V/m, our company's equipment is tightly shielded by various protection technologies. The measured leakage value is only 0.2-1V/m, which is 20 times better than the national standard. Effectively protect the human body and protect other equipment from the high-frequency electric field.

As one of the most professional high frequency welding machine manufacturers in China, Liaoning Yufei High-Frequency Equipment Co., Ltd. is a renowned Chinese company specializing in hf plastic welding machine. Please feel free to contact us if you have any further inquiry.

在线联系供应商

Other supplier products

| Industrial Belt Welder | Mainly application of Industrial Belt Welder Used for industrial belt skirt and belt baffles welding, welding industrial conveyor belt conveyor b... | |

| HF Blister Packaging Welders | Blister packaging is an inexpensive option for creating packages that are durable, transparent, and tamper proof. We make a variety of shapes an... | |

| High Frequency Dryer For Insulation Cardboard | Explore More Insulation Cardboard Drying Machines Products High-Frequency Dryer For Corner Ring Insulation Cardboard mainly applied in drying and f... | |

| HF Industrial Belt Welders | The scope ans application of conveyor belt welding machinein Liaoning Yufei company for treadmill and conveyor belt, treadmill belt, side wall, pro... | |

| HF Welders | The theory of high frequency welding equipment: Under the effect of the high frequency electric field, the positive and negative charges of the su... |

Same products

| YIHUA 8858 BGA Soldering Rework Station | 卖方: 深圳市唯客修科技有限公司 | YIHUA 8858 BGA 焊接返修台 110V 220V 便携式热风枪数字热风吹干机热风枪焊台 规格:输入电压:110V、220V~240V 输出功率:700W 温度范围:100~480摄... | |

| QUICK TR1300A BGA soldering motherboard repair | 卖方: 深圳市唯客修科技有限公司 | 规格:功率:1300W带温度报警功能。电压:110V / 220V 供选择温度范围:100°C~500°C / 212°F-932°F温度稳定性 ±... | |

| QUICK 858D+ 750W 拆焊返修台 | 卖方: 深圳市唯客修科技有限公司 | 升级版 QUICK 858D+ 750W 热风返修台,用于 SMD 主板 BGA IC 焊接维修。 QUICK 858D 700W 热风枪,用于 SMD PCB BGA IC 焊接修复。 原装Q... | |

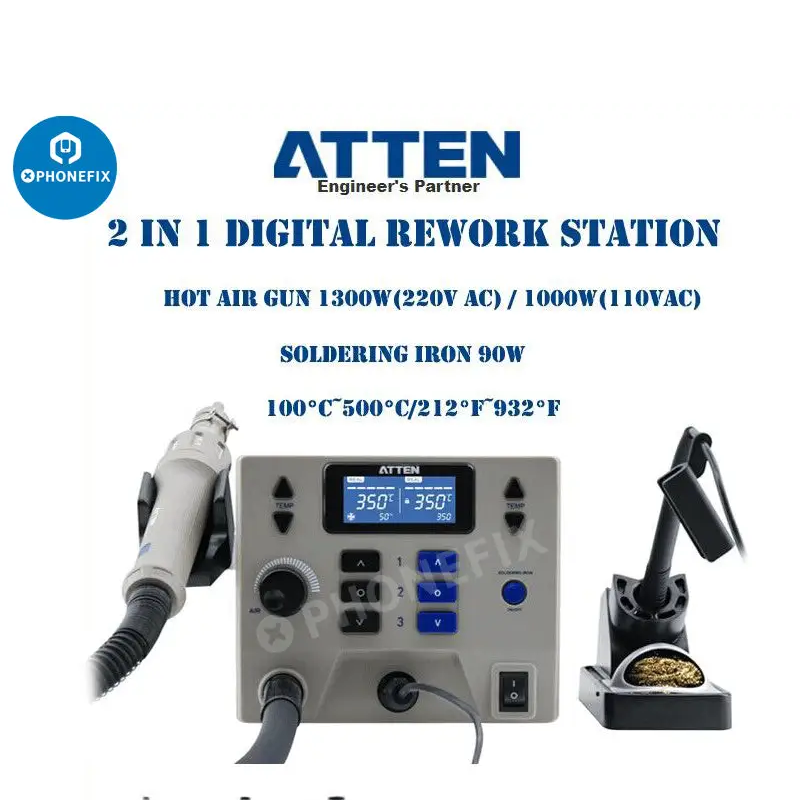

| ATTEN ST-8602D 1300W 烙铁头 | 卖方: 深圳市唯客修科技有限公司 | ATTEN ST-8602D 1300W 带热风枪和烙铁的二合一拆焊台,是ST-862D返修台的升级版。 ATTEN ST-8602D 数字热风焊接返修台,用于 PCB 主板焊接拆焊修复。 用于... | |

| Three Phase Portable DC 380V 220A TIG DC-HF IGBT Inverter TIG/MMA Welding machine | 卖方: Kende Mechanical & Electrical Co., Ltd | ●Advanced features with simple interface● Easy-to-use operation allows you to just set the weldin... |