Eddy Current Testing Equipment

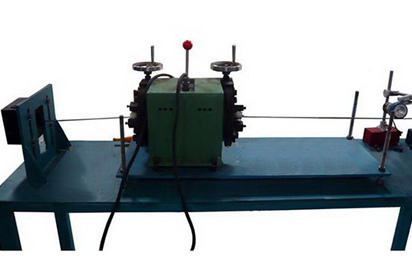

GSET-551 Steel Wire Eddy Current Flaw Detector Brief

Using the eddy current signal processing method and high-performance DSP algorithm, the NDT wire rope testerdetection ability of micro-crack is as high as 0.05mm deep crack.

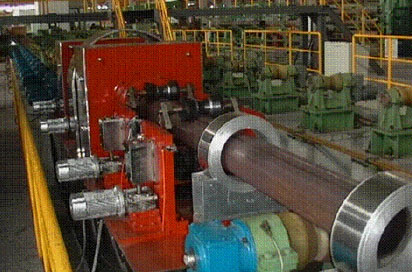

Using computer digital technology and "digital eddy current detection technology" to achieve high-speed data processing capabilities, detection speed can be reached to 1~500m/min. Technology can effectively suppress all kinds of interference signals. It has waveform, amplitude, phase, X-axis and Y-axis signals.

The professional "digital filtering" is adopted to effectively suppress the interference signal in the field and ensure the accuracy and stability of the detection.

Features of GSET-551 Steel Wire Eddy Current Flaw Detector

The detector detects the minimum metal cross-sectional area change and the minimum length of the damage length corresponding to the local damage.

The detector detects the minimum metal cross-sectional area change and the damage length minimum size corresponding to the metal cross-sectional area loss.

The maximum value of the random error obtained by performing multiple consecutive measurements of the same metal cross-sectional area change in the same test sample under the same test environment and conditions within the instrument range.

Within the range of the instrument, the metal cross-sectional area of the test sample is linearly proportional to the absolute value of the maximum deviation between the measured curve of the instrument and the calibration curve fitted by the measured value of the cross-sectional area of the metal.

The value of the metal cross-sectional area loss measured by the instrument minus the actual value of the metal cross-sectional area loss within the instrument's range.

In the range of the instrument range, under the condition of the length loss of the cross-sectional area of the metal, the cross-sectional area loss of the metal on the wire rope measured by the detector is matched with the value of the loss of the cross-sectional area of a group of wire ropes measured by the instrument. The absolute value of the maximum deviation between the calibration curves.

The detector is capable of detecting the resolved minimum distance.

The detector can detect and display changes in metal cross-sectional area loss (LMA) on one channel, and detect and display local damage (LF) on the other channel. The detector recording device can be a computer, graphic recorder or other matches. device.

The detector cannot simultaneously detect and display metal cross-sectional area loss changes and local damage, and can only detect and display one of them. The detector recording signal device can be a computer, a graphic recorder or other matching devices.

The detector principle and composition meet the requirements of the GB/T 21837-2008 standard, and it has a detector for detecting distance display, data storage or recording function.

GSET-551 Steel Wire Eddy Current Flaw Detector performance

|

Detection channel |

Single-channel |

|

Detection speed |

1~500m/min(on-line) |

|

Frequency range |

100Hz-10MHz |

|

gain |

0~99dB,step size 0.1dB |

|

Advanced filtering |

have |

|

High pass |

|

|

Low pass |

1Hz~10000Hz |

|

Phase rotation |

0-360 ° step 1 ° |

|

Synchronized alarm output controlled by an internal and external clock |

|

High precision end and end-to-tail signal removal |

|

High precision real-time, delayed alarm output |

|

Fast digital/analog electronic balance |

|

Memory track delay blanking function |

|

Real-time impedance plane display |

|

The instrument a match any probe |

|

Remote automatic help system |

|

Computer full digital parameter adjustment |

|

Non-equal amplitude phase/amplitude alarm domain |

Nanjing BOKENA Automation System Co., Ltd., originated from the eddy current testing laboratory of the Nanjing University of Technology. It isone of the most professional ndt testing equipment suppliersin China. We sincerely invite and welcome people from all around the world to invest and create more values together.

在线联系供应商

Other supplier products

| Portable Magnetic Flux Leakage Testing Equipment | Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to defects... | |

| Drill Pipe Magnetic Flux Leakage Detector MFL-308 | Specifications: diameter Φ73 / Φ89 mm, length 9.6m or so Detection speed: 6-20 m / min Acceptance criteria: American Petroleum Institute ... | |

| BKNET-999H Copper Tube Eddy Current Flaw Detector | BKNET-999H Copper Tube Eddy Current Flaw Detector brief Eddy current testing is a non-destructive testing technique in which an alternating curre... | |

| Benchtop Magnetic Flux Leakage Testing Equipment | Benchtop magnetic testing equipment MFI Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test pi... | |

| BKNET-101 Automatic Eddy Current Testing | The eddy current testing (BKNET-101) is a fully automated eddy current inspection system that uses large-scale imported integrated circuits combine... |

Same products

| Tandem roller bearing M4CT3278 with shaft 78x32x110.5mm | 卖方: JinHang Precision Bearing Co.,LTD | The tandem roller extruder bearing m4ct3278 that use for PVC screw extruder gearbox, the shaft di... | |

| Tandem roller bearing F-86722 for Rubber extrusion machine | 卖方: JinHang Precision Bearing Co.,LTD | The bearing f-51909 t3ar mainly used in the twin screw plastic extrusion machine gearbox.The bear... | |

| Tandem roller bearing t6ar3278 for the extruder shaft gearbox | 卖方: JinHang Precision Bearing Co.,LTD | The bearing T6 AR 3278 with size 32X78X163.5mm mainly used for the high speed extruder machine ge... | |

| Tandem roller bearing MTCT2468 for Screw extrude gearbox | 卖方: JinHang Precision Bearing Co.,LTD | The bearing M5CT2468 for food/feed/plastic/rubber extrusion machine gearbox use. With high perfor... | |

| twin screw extruder gearbox used t5ar3278 bearing | 卖方: JinHang Precision Bearing Co.,LTD | Bearing T5AR3278 fullsize 32x78x137mm bearing actual picture, Please reference them. Bearing fact... |