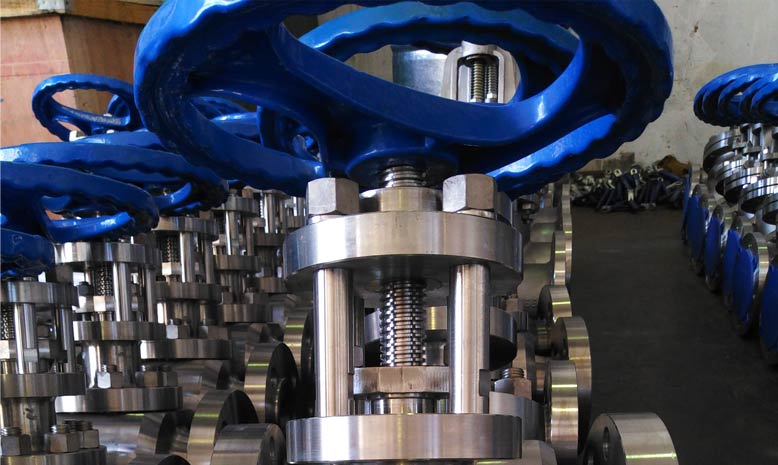

Duplex Plug Valves

Duplex stainless steels are called “duplex” because they have a two-phase microstructure consisting of grains of ferritic and austenitic stainless steel.

Strength: Duplex stainless steels are about twice as strong as regular austenitic or ferritic stainless steels.

Super duplex valvesare used in many industries such as petrochemical, chemical equipment, food processing, oil, and gas.

Corrosion Resistance Of Duplex Plug Valves

As with all stainless steel, corrosion resistance depends mostly on the composition of the stainless steel. For chloride pitting and crevice corrosion resistance, their chromium, molybdenum, and nitrogen content are most important. Duplex stainless steel grades have a range of corrosion resistance, similar to the range for austenitic stainless steels, i.e from Type 304 or 316 (e.g. LDX 2101©) to 6% molybdenum (e.g. SAF 2507©) stainless steels.

The Cost Of Duplex Plug Valves

Duplex stainless steels have lower nickel and molybdenum contents than their austenitic counterparts of similar corrosion resistance. Due to the lower alloying content, duplex stainless steels can be lower in cost, especially in times of high alloy surcharges. Additionally, it may often be possible to reduce the section thickness of duplex stainless steel, due to its increased yield strength compared to austenitic stainless steel. The combination can lead to significant cost and weight savings compared to a solution in austenitic stainless steel.

Duplex Plug Valves applications

Duplex valves are versatile and can be used in various applications where reliable and efficient flow control is required, for example: chemical processing, oil and gas pipelines, water treatment, power generation and so on.

For more informationabout china valve, please feel free to contact us!

在线联系供应商

Other supplier products

| Hastelloy Ball Valves | Hastelloy Ball Valves Hastelloy ball valvescontain ultra-low carbon and high Ni, Mo and Cr elements, which belong to corrosion-resistant and high ... | |

| Titanium Ball Valves | Due to their excellent characteristics, custom titanium valvesare widely sought after. Especially in the automotive, aviation, shipping and PTA ind... | |

| Duplex Globe Valves | The microstructure of the duplex stainless steel globe valveconsists of a mixture of an austenitic phase and a ferrite phase. Therefore, the duplex... | |

| Globe Valves | A china manual gate valveis a linear motion valve and is primarily designed to stop, start and regulate flow. The disk of a Globe valve can be tota... | |

| Stainless Steel Globe Valves | Cast steel globe valvefeature molybdenum-alloyed construction and offer high resistance to pitting corrosion. Globe valves are named for their sphe... |

Same products

| "High-reliability Support ring Y10-4 for power station | 卖方: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "High-reliability Support ring Y10-4 for power station Deyang YOYIK have power plant professional... | |

| "Wear Resistance dn50 globe valve WJ25-F1.6P for thermal power plant | 卖方: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Wear Resistance dn50 globe valve WJ25-F1.6P for thermal power plant YOYIK professional productio... | |

| High-efficiency Superheater outlet plug valve SD61H-P61305V SA-182 F92 for power generation | 卖方: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "High-efficiency Superheater outlet plug valve SD61H-P61305V SA-182 F92 for power generation Deya... | |

| Automated Sealing gasket for corrugated pipe shut-off valve KHWJ25F3.2P for power station | 卖方: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Automated Sealing gasket for corrugated pipe shut-off valve KHWJ25F3.2P for power station Is a m... | |

| Class 1500 LB gate valve | 卖方: Magpie Valve Packing Gasket Co., Ltd | Product Name: Low-EmissionPacking Setfor Class 1500 LB API 6D Gate ValveModel: M600Size: ID 68 mm... |