EN 13889 Shackle

EN 13889 shacklespecifies the design, materials, testing, and marking requirements for shackles used in lifting applications. It requires that the shackles be manufactured from high-quality materials and meet certain strength and durability criteria. The standard also specifies testing procedures to ensure that the shackles can withstand the loads and forces they are designed to carry.

When selecting an BS EN 13889shackle, it is important to choose the right size and working load limit for the specific task at hand to ensure safe and effective use. It is also important to ensure that the shackle is marked with the appropriate information, including the working load limit, the manufacturer's name or trademark, and the EN 13889 standard designation.

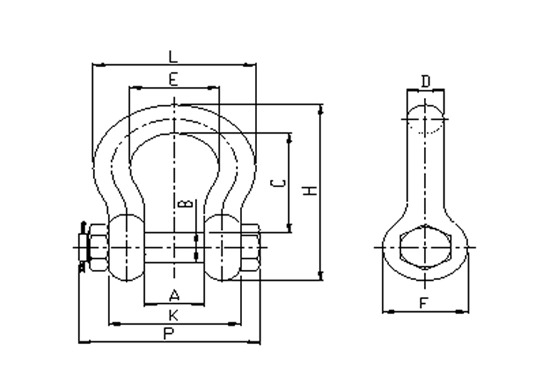

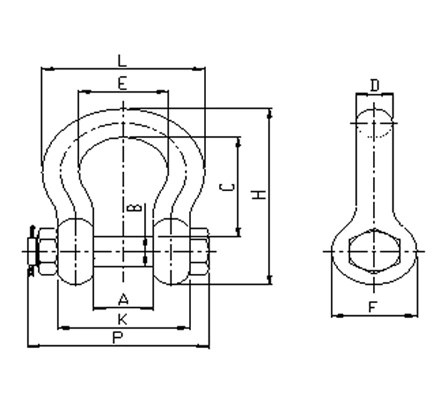

Specifications of EN 13889 Shackle

|

Size |

WLL |

Weight |

Dimensions |

Tolerance |

||||||||||

|

(T) |

(Kg) |

A |

B |

C |

D |

E |

F |

H |

K |

L |

P |

|||

|

3/16" |

36 |

±5% |

||||||||||||

|

1/4" |

8 |

42 |

±5% |

|||||||||||

|

5/16" |

31 |

19 |

53 |

49 |

±5% |

|||||||||

|

3/8" |

1 |

63 |

36 |

±5% |

||||||||||

|

7/16" |

19 |

43 |

27 |

65 |

±5% |

|||||||||

|

1/2" |

2 |

16 |

47 |

33 |

30 |

46 |

±5% |

|||||||

|

5/8" |

27 |

19 |

60 |

16 |

42 |

39 |

106 |

59 |

74 |

97 |

±5% |

|||

|

3/4" |

71 |

19 |

51 |

47 |

125 |

89 |

109 |

±5% |

||||||

|

7/8" |

84 |

22 |

58 |

54 |

147 |

102 |

123 |

±5% |

||||||

|

1" |

43 |

96 |

25 |

68 |

60 |

166 |

93 |

118 |

139 |

±5% |

||||

|

1 1/8" |

46 |

107 |

74 |

103 |

130 |

149 |

±5% |

|||||||

|

1 1/4" |

12 |

119 |

32 |

82 |

76 |

208 |

146 |

171 |

±5% |

|||||

|

1 3/8" |

57 |

38 |

131 |

35 |

89 |

84 |

228 |

127 |

159 |

186 |

±5% |

|||

|

1 1/2" |

17 |

148 |

38 |

98 |

92 |

254 |

174 |

194 |

±5% |

|||||

|

1 3/4" |

25 |

73 |

177 |

45 |

127 |

109 |

303 |

163 |

217 |

328 |

±5% |

|||

|

2" |

35 |

197 |

51 |

146 |

127 |

341 |

248 |

260 |

±5% |

|||||

|

2 1/4" |

95 |

63 |

221 |

57 |

160 |

143 |

283 |

209 |

274 |

302 |

±5% |

|||

|

2 1/2" |

55 |

105 |

264 |

184 |

150 |

455 |

235 |

321 |

328 |

±5% |

||||

|

3" |

85 |

67 |

127 |

85 |

328 |

76 |

200 |

165 |

546 |

279 |

371 |

378 |

±5% |

|

|

3 1/2" |

120 |

113 |

133 |

95 |

371 |

92 |

229 |

203 |

632 |

323 |

432 |

425 |

±5% |

|

|

4" |

150 |

141 |

140 |

107 |

368 |

104 |

254 |

228 |

340 |

457 |

452 |

±5% |

||

|

Production Standard |

Meet EN13889 and US Federal Specification RR-C-271F, Type IVA, Grade B |

|||||||||||||

|

Production Process |

Drop Forging |

|||||||||||||

|

Material Grade |

Carbon Steel for Shackle Body and Alloy Steel For Shackle Pin |

|||||||||||||

|

Heat Treatment |

Quenching and Tempering |

|||||||||||||

|

Safety Factor |

6:01 |

|||||||||||||

|

Finish |

Hot Dip Galv. |

|||||||||||||

|

Temperature Range |

-20℃up to +200℃/td> |

|||||||||||||

|

Fatigue properties |

Under 1.5 Times of working load limit,the Fatigue test could reach over 20000 Cycles. |

|||||||||||||

|

Low temperature Impact Test |

Charpy V-notch testing -20℃?with Min. 27J |

|||||||||||||

|

Supply Certificate |

Mill Test Certificate According to EN 10204 3.1; Under request, CCS/ABS/DNV third party |

|||||||||||||

|

Inspection certificate can be supplied, but the cost would be extra to buyer account. |

||||||||||||||

If you are looking for a reliable rigging supply company, please contact us, and we will be your best to meet all the needs of customers.

在线联系供应商

Other supplier products

| G2150 Shackle | It's worth noting that G2140 and G2150 shackles are designed and manufactured in accordance with different standards. The G2140 shackle is manufact... | |

| G80 Eye Self Locking Hook | A popular lifting hook for attaching loads to chains or cables in commercial and industrial applications is the G80 Eye Self Locking Hook. Heavy... | |

| G2130 Shackle | G2130 Shackleare high tensile safety bolt anchor shackles with a working load limit of 10,000 lbs and a breaking load limit of 30,000 lbs. They are... | |

| Loader Tines | Tractor loader tines for salecome in a variety of shapes and sizes to suit different applications. Some are designed with curved or angled tines to... | |

| G80 Eye Grab Hook | The hook is made of high-strength alloy steel and is designed to withstand heavy loads. It features an eyelet at the top that allows it to be easil... |