CANNULA MAKING MACHINE

The Welinktech cannula making machine, cannula manufacturing machineis a specialized equipment used to produce medical-grade cannulas used in procedures such as venipuncture and surgery. It employs advanced technology to produce precise, sterile, and high-quality cannulas.

TYPES OF CANNULA MAKING MACHINE

01

Cannula Welding Machine

Cannula welding machines are used in the medical industry for welding the stainless steel cannulas used in syringes and other medical devices.

02

Cannula Diameter Reducing Machine

Cannula diameter reducing machines are used to reduce the diameter of cannulas used in medical devices without compromising the structural integrity.

03

Double-heads Straightening Machine

Double-heads straightening machines are used in the medical industry to straighten and align cannulas with precision, ensuring accuracy and consistency in the manufacturing process.

04

Needle Tube Polycondensation Film Machine

Needle tube polycondensation film machines are used to produce polycondensation films used in the manufacturing of needle tubes and other medical devices.

05

Automatic Needle Tube Cutting Machine

Automatic needle tube cutting machines are used in the medical industry to quickly and accurately cut needle tubes into desired lengths for various medical devices.

06

Automatic Needle Tube Collocating Machine

Automatic needle tube collocating machines are used to assemble needle tubes with precision, making the manufacturing process efficient and error-free.

07

Automatic Cannula Grinding Machine

Automatic cannula grinding machines are used in the medical industry to grind and sharpen stainless steel cannulas used in syringes and other medical devices.

08

Automatic Cannula Electrolyzing Machine

Automatic cannula electrolyzing machines are used in the medical industry for electrolyzing cannulas to improve their surface characteristics and surface finish.

09

Automatic Cannula Ultrasonic Cleaning Machine

Automatic cannula ultrasonic cleaning machines are used to clean cannulas thoroughly, removing all traces of dirt, debris, and contaminants for safe medical use.

PRECISION AND ACCURACY IN CANNULA MANUFACTURING

MAINTENANCE TIPS FOR CANNULA MAKING MACHINES

1

It is important to clean and maintain the iv cannula manufacturing machine, iv cannula making machineregularly to avoid any blockages or damages. The debris or dust that accumulates on the machine parts can cause issues in the production process.

2

Lubrication of the machine parts is important as it helps in reducing friction and wear and tear, thus increasing the lifespan of the machine.

3

Regular checking of the machine parts for any wear and tear is crucial as it helps in replacing the worn-out parts and improving the overall functioning of the machine.

4

The electrical components of the machine should be checked regularly to ensure that they are in good condition and functioning properly.

5

The machine should be calibrated regularly to ensure accurate measurements and consistent production.

6

Hiring a professional technician for regular maintenance checkups can help in identifying any potential problems and addressing the same before they cause any major issues.

7

Proper storage of the machine is crucial to avoid any damages caused by environmental factors such as heat, moisture, or dust.

As a medical molding manufacturer, we can offer sorts of related products for sale, anything you need, please contact us.

在线联系供应商

Other supplier products

| CLAMP BODY MOLD | A clamp mouldis a type of injection mold that is designed to produce the clamp body component used in clamping systems. The clamp body is a type of... | |

| CANNULA MAKING MACHINE | The Welinktech cannula making machine, cannula manufacturing machineis a specialized equipment used to produce medical-grade cannulas used in proce... | |

| CONNECTOR ASSEMBLY MACHINE | The Welinktech Connector Assemble Machine is a cutting-edge device designed to create a range of connectors for various industrial applications, in... | |

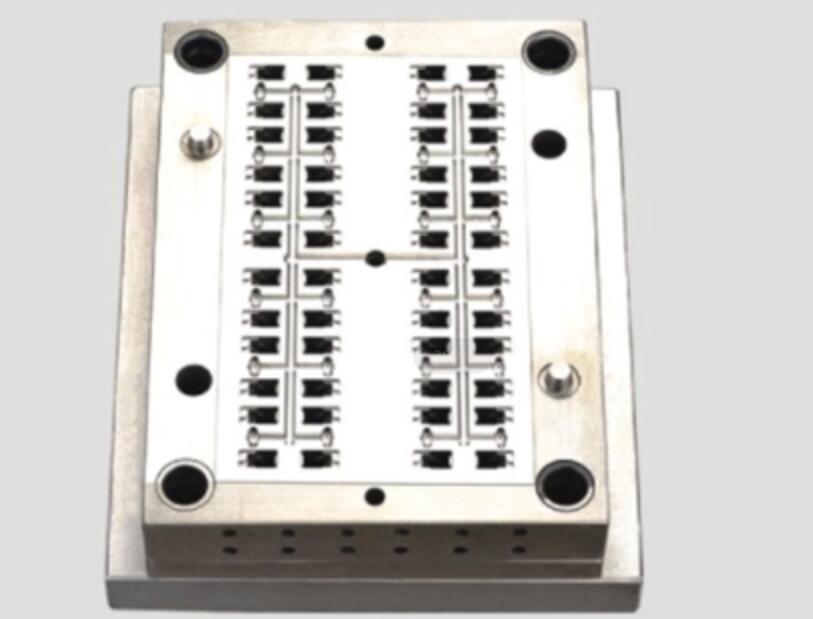

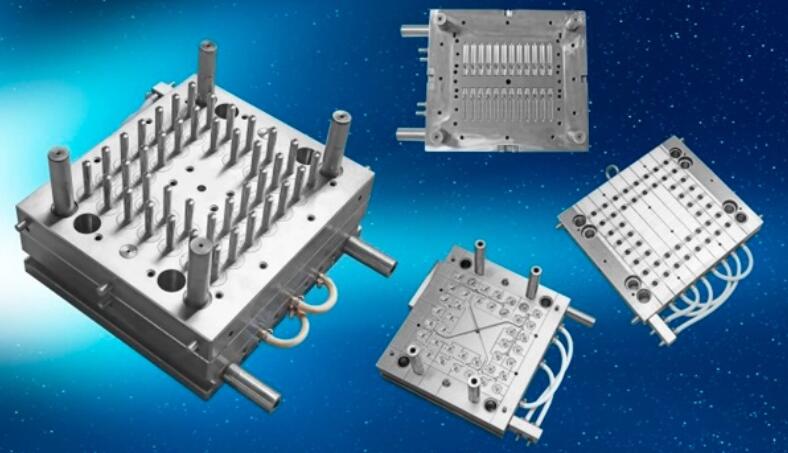

| NEEDLE MOLD/MOULD | The LINKPLUS Needle Moldis a specialized tool used in the production of medical needles. It is designed with advanced technology to ensure high pre... | |

| SAFETY SYRINGE MOLD | LINKPLUS Safety syringe injection moldingare designed to manufacture syringes with built-in safety mechanisms. These molds come in different shapes... |

Same products

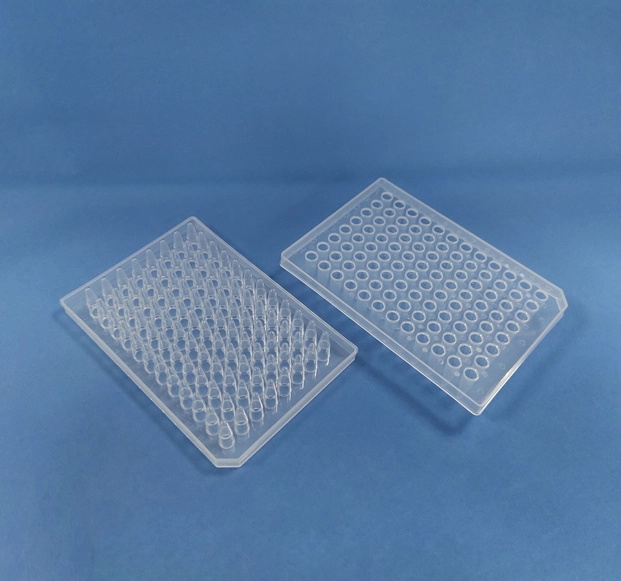

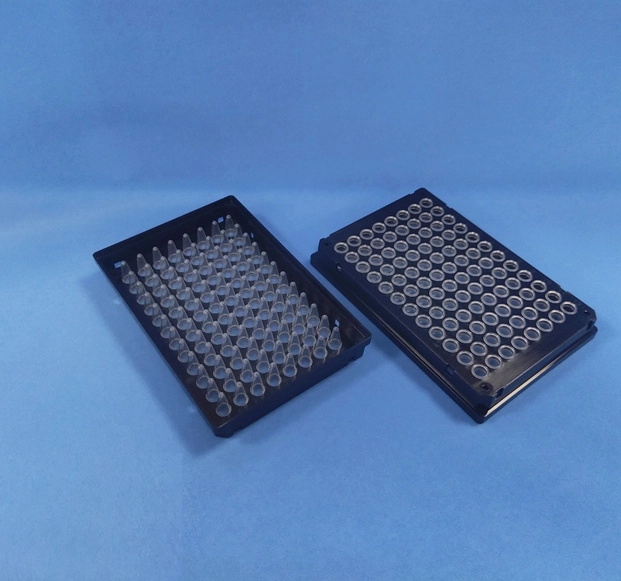

| 96-Well PCR Plate, Half-Skirted | 卖方: Zhejiang Yikang Medical Technology Co., Ltd. | The 96 well half skirted pcr plateis designed to provide superior performance and convenience for... | |

| 96-Well PCR Plate, Full-Skirted | 卖方: Zhejiang Yikang Medical Technology Co., Ltd. | The hard shell pcr plates 96 well thin wallis an essential lab tool for researchers and scientist... | |

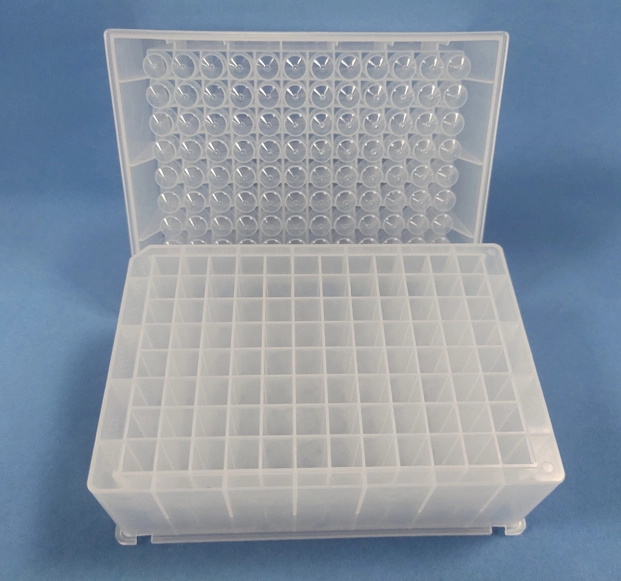

| 96 Square Well Plate | 卖方: Zhejiang Yikang Medical Technology Co., Ltd. | The 96 square well plateis a crucial tool in the field of medical and biological research. This p... | |

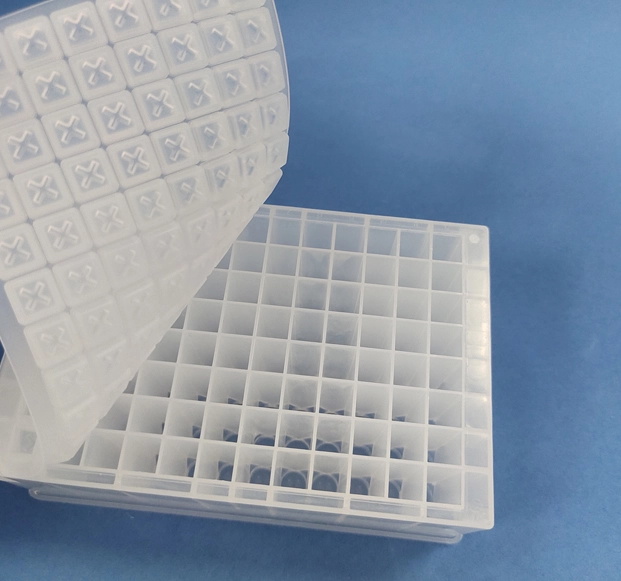

| 96 Silicone Mat, Square Plug | 卖方: Zhejiang Yikang Medical Technology Co., Ltd. | The 96 well plate sealing matwith Square Plug is a game-changer for laboratories using 96 square ... | |

| 96 Round Well Plate | 卖方: Zhejiang Yikang Medical Technology Co., Ltd. | A 96 round well plateis a common scientific tool used in laboratory research. It consists of 96 r... |