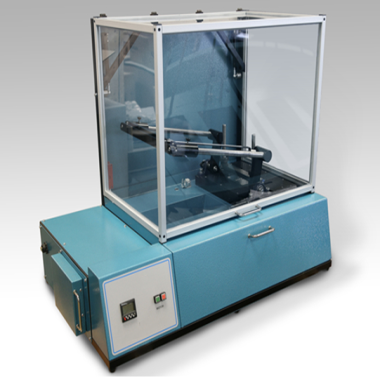

Shoe Shank Stiffness Tester

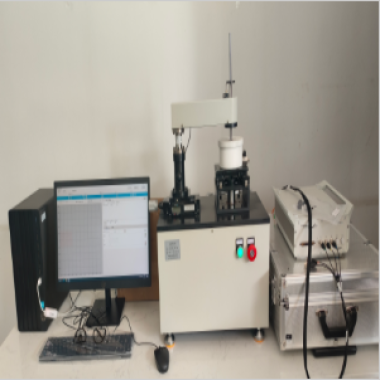

This machine evaluates the thermal insulation and moisture permeability performance of the entire shoe by measuring its heat retention, moisture absorption, and breathability, and tests it together with long socks.

The test takes into account the effects of the sole, upper, and lining, as well as the influence of stitching and various types of socks.

Application

1. Footwear Manufacturers: Optimize the combination of upper/sole materials (e.g., mesh fabric, breathable leather, thermal insulation cotton) during the R&D phase, and conduct random inspections of product breathability/thermal insulation consistency during the production process;

2. Outdoor/Functional Footwear Sector: Test the breathability and moisture-wicking capabilities of athletic shoes, hiking boots, and safety shoes, or the thermal insulation performance of snow boots and cold-weather boots, to match the demands of outdoor scenarios;

3. Quality Inspection and Compliance: Conduct breathability/thermal insulation performance testing of footwear products according to standards such as GB/T 3903.14 and ISO 20344 to ensure that products comply with industry standards;

4. Brand Quality Control: Verify the authenticity of the breathability/thermal insulation indicators advertised for products to enhance product competitiveness in the market.

Standards

SATRA TM256: Flexural and torsional stiffness testing for athletic, safety, and casual footwear.

SATRA TM194: Dynamic fatigue resistance evaluation for shoe midsole and outsole integrity.

Feature

Dynamic Testing System:

Servo-electric actuator with 0–50° programmable flex range.

360° torsion axis with ±180° rotational limits.

Precision Fixturing:

Quick-change shoe clamps for US Men’s 5–15 (EU 38–50) sizes.

Adjustable torsion line alignment for varied shoe geometries.

Sensor Suite:

1.000 N load cell for flexural force measurement.

50 N·m torque sensor with overload protection.

Software Bundle:

ShoeFlex Pro™: Automated stiffness coefficient calculation (ASTM D790 equivalent).

Fatigue Analyzer: Predicts lifespan via stress-cycle (S-N) curve modeling.

Safety Systems:

Emergency stop with E-Stop loop monitoring.

Over-torque shutdown at 110% of rated capacity.

Parameters

| Specification | Details |

|---|---|

| Flex Angle Range | 0° to 50° (adjustable in 1° increments) |

| Torsion Range | ±180° (360° continuous rotation) |

| Test Speed | 30 cycles/minute (1–60 Hz adjustable) |

| Load Capacity | 1.000 N (flex) |

| Angular Accuracy | ±0.1° (±0.05° with calibration kit) |

| Power Supply | 220V/50Hz (110V/60Hz available) |

| Dimensions (W×D×H) | 600mm × 500mm × 1.100mm |

| Weight | 95 kg (net) |

Accessoriess

Standard Kit:

5 × Universal shoe clamps (adjustable width).

USB data cable and PC software license.

Advanced Analytics:

Fatigue Predictor: AI-driven lifespan estimation module.

CloudLink: Remote monitoring for global teams.

Calibration Services:

Annual recalibration with NIST-traceable certificate.

Safety Upgrades:

Explosion-proof enclosure for solvent-resistant testing.

HEPA filtration for particle-sensitive labs.

Consumables:

20 × Disposable sample alignment markers.

1L Silicone lubricant for high-cycle testing.

Test Procedures

1. Pre-test Preparation

Check that the instrument's cooling/heating system and temperature monitoring probes are functioning correctly. Pre-cool/pre-heat the test chamber to the set temperature (e.g., -10℃, 0℃), calibrate the temperature sensors, and ensure uniform temperature distribution within the chamber.

2. Sample Preparation and Installation

Place the shoes in a room temperature environment for 2 hours to equilibrate. Record the shoe material characteristics (e.g., thickness of insulation cotton, upper material). Insert the temperature sensor simulating a foot into the shoe, fix the shoe in the designated position in the test chamber, ensuring the sensor is in close contact with the inside of the shoe.

3. Parameter Settings

Select the "Insulation Test Mode," set the chamber ambient temperature (e.g., -15℃~5℃, adjust according to test requirements), test duration (e.g., 2 hours), and temperature acquisition interval. Save the parameters.

4. Starting the Test

Close the chamber door. The instrument maintains the set ambient temperature, continuously monitors the temperature change of the simulated foot inside the shoe, and records the temperature decay curve.

5. Test Monitoring

During operation, observe the temperature stability inside the chamber and record whether the temperature inside the shoe remains within the acceptable range (e.g., ≥10℃), preventing temperature fluctuations caused by equipment malfunction.

6. Test Completion and Cleaning

After the test is completed, the instrument automatically shuts down. After the chamber temperature returns to room temperature, remove the shoes, record the insulation performance data (e.g., temperature decay rate, lowest maintained temperature), clean the test chamber and sensors, turn off the power, and prepare the test report.

在线联系供应商

Other supplier products

| Shirley Moisture Permeability Tester | Introduction Shirley moisture permeability tester is used to detect water vapor permeability of textiles and textile composites, especially sports... | |

| STD Lithium battery explosion test chamber | Introduction: Lithium battery combustion and explosion experiment chamber is mainly used for thermal runaway combustion and even explosion experim... | |

| Respirator Fit Tester | PortaCount Respirator Fit Tester: Qinsun assesses the overall integrity of masks by performing an aerosol leak test utilizing the PortaCount Respi... | |

| Electrochemical Corrosion and Wear Testing Machine | Electrochemical corrosion and wear testing machines are widely used in materials science, mechanical engineering, electronic engineering, aerospace... | |

| Environmental Stress Cracking Resistance Tester | This instrument is a testing device recommended according to standard requirements. It is a specialized device designed specifically for environmen... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | 卖方: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | 卖方: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | 卖方: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | 卖方: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | 卖方: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |