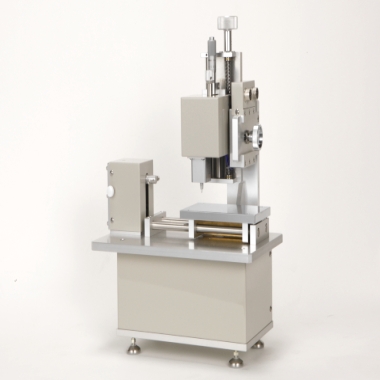

Vacuum Ball - Disk Friction Tester

A vacuum ball-on-disk friction tester is a device used to simulate friction and wear behavior under actual operating conditions, in order to evaluate the performance of materials, lubricants, or other wear-resistant materials.

Application

The vacuum ball - disk friction tester is a device specifically used for evaluating the sliding friction coefficient of point contact and the wear life of materials under vacuum and different atmospheric environment conditions. Its main purposes include:

Material Friction Performance Evaluation

- Simulate the actual friction conditions of materials in a vacuum or specific atmospheric environment, test the friction coefficient of materials, and evaluate their friction performance. - Test the friction behavior of materials under different loads and speeds to obtain friction performance data, providing a basis for material research, development, and optimization.

Standards

ASTMD4172-94:Standard Test Method for Wear Preventive Characteristics of Lubricating Fluid (Four-Ball Method)

ASTMD2266-91:Standard Test Method for Wear Preventive Characteristics of Lubricating Grease (Four-Ball Method)

SH/T0189-92:Test Method for Anti-wear Performance of Lubricating Oils (Four-Ball Machine Method)

ASTM G99:Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus

Feature

Simulating actual working conditions: The machine can simulate the friction and wear behavior of materials under actual working conditions, such as sliding friction, rolling friction, and contact friction.

Friction pair design: Using pin-on-disk and ball-on-disk configurations as friction pairs, resulting in a long service life and low maintenance costs.

Precise control of test parameters: The testing machine can precisely control test parameters such as load, speed, and time through a computer control system.

Easy operation: The testing machine features a user-friendly interface design for simple and intuitive operation.

Energy-saving and environmentally friendly: The testing machine utilizes advanced energy-saving technology to effectively reduce energy consumption and minimize environmental pollution.

Parameters

| Items | Details |

|---|---|

| Test Standard | ASTM G99. G133. G59. G102. G119 |

| Load | 0.25 - 200N |

| Speed | 0.1 - 3000rpm |

| Friction Force (presumably a specified test condition) | 100N |

| Size | 650mm * 400mm * 700mm |

| Weight | 80KG |

| Power Supply | 220V/50Hz |

Accessoriess

Vacuum gauge, cooling water system, standard test sphere, etc.

Test Procedures

- Calculate the wear life of materials by measuring the friction and wear conditions when the ball specimen rotates on the disk specimen. - Evaluate the performance changes of materials during long - term friction and wear processes, providing support for the assessment of material reliability and durability.

- Friction tests can be carried out in a vacuum environment to simulate the friction behavior in special application scenarios such as space and the nuclear industry.

- By adjusting the atmospheric environment, such as argon, nitrogen, etc., study the influence of different atmospheres on the friction performance of materials.

Lubricating Film Performance Evaluation

- For lubricating film materials, their wear life can be evaluated by testing the number of rotations before lubrication failure.

- Study the friction performance of lubricating films under different conditions to provide support for the research, development, and optimization of lubricants.

When the vacuum ball - disk friction tester conducts tests, it may need to comply with the following relevant standards or specifications (the specific standards may vary depending on the instrument model and application field):

Material Performance Testing Standards

Performance testing standards for specific material types, such as metallic materials, polymer materials, ceramic materials, etc.

Vacuum Environment Testing Standards

Such as standards and specifications regarding vacuum degree control and atmospheric environment simulation.

在线联系供应商

Other supplier products

| ASTM G154 UV Accelerated Aging Chamber | Features and Benefits 1.TheUV accelerated aging chamberuses fluorescent ultraviolet lamps to simulate the ultraviolet part of sunlight: the UVA340... | |

| Battery Powder resistivity meter丨Battery Powder resistivity Tester | Standards YS/T 587.6-2006 GB/T 24525-2009 GBT 30835-2014 Product Advantages Unmatched Measurement Flexibility Dual-probe compatibility: Swi... | |

| Rubber hose outer coating wear testing machine | The Rubber Hose Outer Coating Wear Testing Machine is a precision laboratory and production testing instrument designed to evaluate the abrasion re... | |

| Micro Controll High-temperature Friction Tester | Applicable Standards When conducting tests, the microcomputer - controlled high - temperature friction testing machine usually needs to comply wit... | |

| Sliding bearing PV friction testing machine | The testing machine can monitor the changes in friction force and the wear condition of the sample surface in real time during the test, and also p... |

Same products

| Gas Oxidizing Property Tester | 卖方: Standard International Group (HK) Limited | Product Description Conforms to ISO 10156-2010 “Gases and Gas Mixtures Selection of Cylind... | |

| Battery Powder Compaction Density Measurement System | 卖方: Standard International Group (HK) Limited | The Battery Powder Compaction Density Measurement System is a precision testing system designed... | |

| Battery Powder resistance tester | 卖方: Standard International Group (HK) Limited | The Powder Resistivity Meter is a precision testing system designed to measure electrical resisti... | |

| KES-SESRU surface roughness/friction tester | 卖方: Standard International Group (HK) Limited | TheRoughness/Friction Tester analyzes hand movements-particularly, strokes-performed by artisans ... | |

| Air Permeability Tester STD- F8 | 卖方: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... |