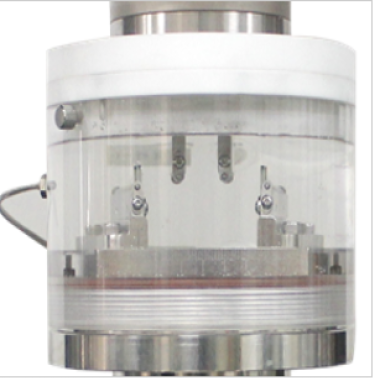

Leather edge oil fatigue testing machine

The Leather Edge Oil Fatigue Testing Machine is designed to evaluate the fatigue resistance of edge coatings applied on leather, synthetic leather, or recycled leather. Edge oil, typically composed of polyvinyl chloride, polyurethane, and other resins, is applied to leather edges for protection and aesthetic finishing. This instrument simulates repeated mechanical stress by kneading or rolling the coated leather edges under controlled loads, assessing durability and performance under real-world conditions.

Application

(1) Testing leather edge oil fatigue resistance in footwear manufacturing.

(2) Quality assessment of leather goods such as handbags, belts, and wallets.

(3) Evaluation of synthetic leather and PU-coated fabrics for edge coating durability.

(4) R&D of new edge oil formulations and coating materials.

(5) Inspection of recycled leather products for coating performance.

(6) Testing of colored or pigmented edge coatings to ensure color stability and adhesion.

(7) Industrial quality control for leather processing plants and finishing workshops.

Standards

(1) QB/1333-2018 – Leather edge oil fatigue resistance testing standard.

(2) QB/1618-2018 – Leather products edge coating performance specification.

(3) QB/T 5246-2018 – Testing method for coated leather edge fatigue.

(4) ISO 11640 – Leather — Tests for color fastness (optional for related edge oil evaluation).

(5) ASTM D1790 – Standard test method for flexing resistance of coated leather.

(6) EN ISO 5402 – Leather and coated leather — Determination of surface durability.

Features

(1) Touchscreen controller for easy operation and digital parameter setting.

(2) Adjustable transverse speed and travel for precise simulation of mechanical stress.

(3) Multi-directional sample clamps allowing both longitudinal and lateral movement.

(4) Configurable load-bearing system for testing under various applied weights.

(5) Automated counting system up to eight digits for long-cycle tests.

(6) Compact and robust design suitable for laboratory and production environments.

Parameters

| Parameter | Specification |

|---|---|

| Longitudinal Loading Mode | 200g – 5000g superimposed weight |

| Lateral Travel | 0 – 50 mm adjustable |

| Fixture Height | 45 mm |

| Transverse Speed | 0 – 120 ±1 times/min |

| Controller | Touchscreen, speed and cycle count control |

| Sample Clamps | Bidirectional movement (left/right & forward/backward) |

| Dimensions | [Dependent on manufacturer, typical bench-top size] |

| Power Supply | AC220V, 50Hz |

Accessories

(1) Sample clips (pair)

(2) Calibration weight set

(3) Power cable

(4) Product qualification certificate

(5) User manual

(6) Delivery and acceptance documentation

Test Procedures

(1) Prepare the leather sample with edge oil applied.

(2) Install the sample in the clamps, ensuring proper alignment.

(3) Set the desired load on the longitudinal loading system.

(4) Adjust transverse speed and travel distance according to the testing plan.

(5) Start the machine and monitor the test cycle.

(6) Record the number of cycles until visible fatigue, cracking, or failure occurs.

(7) Analyze results for edge oil performance and durability.

Maintenance Information

(1) Regularly clean clamps and moving parts to prevent residue buildup.

(2) Lubricate mechanical joints and guide rails periodically.

(3) Verify load calibration and speed accuracy before each test.

(4) Keep the instrument in a dry, temperature-controlled environment.

(5) Inspect touchscreen and electrical components for damage or wear.

在线联系供应商

Other supplier products

| Metal ring friction and wear testing machine | Evaluate the wear resistance of the material: By simulating the friction process, real-time monitoring of friction, temperature, wear and other pa... | |

| Circuit Integrity Under Fire Conditions Apparatus BS 6387,cable fire performance tester | Standard: BS 6387 Feature Control cabinet parameters: 1.With double flow meters and pressure regulators. 2.Automatic control of the testing pr... | |

| Femoral Condyles Components Fatigue Performance Tester | Standard ASTM WK51649: Specifies fatigue testing protocols for metallic femoral components in total knee arthroplasty, including F-N curve generat... | |

| Textile surface burning tester丨Textile surface burning test machine | Textile surface burning testeris designed by adopting the latest technology, suitable for determining the fabric surface burning time of fluffy t... | |

| Bio-absorbable Internal Fixation Plates and Screws Test device | Standard YY/T 0509-2009 (China): Specifies mechanical testing protocols for orthopedic plates/screws made of hydrolyzable polymers, including axia... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | 卖方: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | 卖方: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | 卖方: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | 卖方: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | 卖方: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |