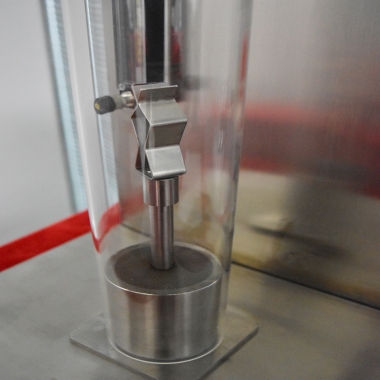

Adhesion Tester

The adhesion tester is a device specifically used to detect the strength of the adhesion of materials.

Applications

The adhesion tester has extensive application value in multiple fields, including but not limited to: - Medical Field: It is used to evaluate the adhesion performance of medical products such as medical gels, dressings, and patches, ensuring that they can stably adhere to the skin in practical applications and exert therapeutic effects. - Cosmetics and Skin - care Industry: It tests the adhesion of cosmetic gel products, facial masks, eye creams, etc., to ensure that they can closely fit the skin during use and enhance the product's effectiveness. - Food Manufacturing Industry: It is used to detect the adhesion performance of food - grade gels, packaging materials, etc., ensuring their stability during food processing, packaging, and transportation. - Adhesive Industry: It tests the adhesion of various adhesives, adhesive tapes, labels, etc., to evaluate their quality and performance. - Materials Science Field: It studies the adhesion performance of materials, providing basic data support for material development and application.

Standards

- Specific standards for different test objects, such as the adhesion test standards for medical gels, cosmetics and skin

- care products, food packaging materials, etc.

- General standards in the adhesive industry, such as GB/T 2792 Test Method for 180°Peeling Strength of Pressure

- Sensitive Adhesive Tapes, ASTM D3330 Standard Test Method for Peel Adhesion of Pressure - Sensitive Tape, etc. These standards specify in detail the test methods for the adhesion tester, specimen preparation, test conditions, etc., providing a unified standard for the use of the tester.

Features

1. 7-inch touchscreen control, stylish human-machine interface

2. Lead screw drive system, greatly improving the accuracy of transmission displacement and enabling stepless speed regulation.

3. Allows for parameter setting, printing, clearing, calibration, and other operations.

4. Calibration interface password protected to prevent errors in calibration force values due to accidental operation.

5. Features power-off memory, overload protection, and line position protection.

6. The instrument has applied for a patent for its sensor protection device function, patent number: ZL.8

7. Equipped with a standard USB interface and a printer interface for easy connection to a computer.

8. The instrument can complete tests independently, and the mini printer automatically prints the test results.

Technical Parameters

| Technical Parameter | Specification |

|---|---|

| Measurement Range | Usually covering 0 - 30000mN or wider (adapts to different materials). Some devices have a smaller range (e.g., 0.01N - 100N), suitable for materials with relatively low adhesion. |

| Measurement Accuracy | Generally grade 0.5 or higher; ensures the accuracy of test results. |

| Stroke | Usually 650mm or longer; meets requirements of different specimen sizes and test methods. |

| Pressing Roller Mass | Usually 2000g±50g; applies pressure to the specimen to ensure tight adhesion between the specimen and the test plate. |

| Test Speed | Adjustable range: generally 1 - 500mm/min (stepless speed regulation) to simulate different peeling speeds; some devices have a wider speed-adjustment range. |

| External Dimensions | Usually about 880mm (length) × 320mm (width) × 400mm (height); facilitates placement and movement (dimensions vary by brand/model). |

| Power Supply | Usually AC 220V 50Hz (ensures normal operation of the tester); some devices support other voltages and frequencies. |

Accessoriess

Standard Configuration: Main unit, standard fixtures, mini printer

Optional Accessories: Professional software, communication cable, test plate, standard pressure roller, sampling knife, custom-made non-standard fixtures

Note: This machine can operate independently. If connection to a computer is required, the computer must be provided by the user. The mini printer is thermal.

Test Procedures

1. Equipment Preparation

Connect to AC 220V 50Hz power supply. Use a standard adhesion sample calibration device conforming to GB/T 2792 (ensuring measurement accuracy of 0.5 grade or higher). Confirm that the pressure roller (2000g±50g), clamps, and other components are in normal condition.

2. Sample Preparation

According to the test object (e.g., medical adhesive removal, food packaging materials),

cut the sample according to the corresponding standard (e.g., ASTM D3330) (e.g., for 180-degree peel tests, the sample size must match). Clean the sample and test plate surfaces (remove impurities to avoid affecting adhesion).

3. Parameter Settings

Select the compliant standard (e.g., GB/T 2792) through the instrument interface, set the measurement range (e.g., 0-30000mN), and test speed (1-500mm/min, select as needed). 4. Sample Adhesion and Clamping

Affix the sample to the test plate and roll it back and forth with the pressure roller a specified number of times (e.g., the number of rolls required by the standard) to ensure a tight fit between the sample and the test plate.

Then, fix the test plate/sample to the instrument fixture, aligning it with the force direction of the peel/adhesion test (e.g., the fixture angle for a 180-degree peel).

5. Start the Test

After confirming that the clamping and parameters are correct, start the test program. The instrument will automatically complete the adhesion force test at the set speed and record the force value data in real time.

6. Result Processing

After the test, export the data and determine whether the adhesion force meets the requirements by referring to the corresponding standard (e.g., ASTM D3330). If multiple tests are required, repeat the sample clamping and testing steps.

7. Post-processing

Remove the sample, clean the fixture, pressure roller, and test plate, and turn off the equipment power.

在线联系供应商

Other supplier products

| Temperature and Low Air Pressure Test Chamber | Features and Benefits 1.The test chamber combines a wide temperature and humidity range, low pressure range, can complete a variety of complex low... | |

| Motor Accessories Combustion Testing Machine, Fmvss 302,ISO 3795 | Introduction: This machine is designed according to ISO3795 standards and relevant clauses. Apply to identify vehicles (cars, multipurpose passeng... | |

| Oxygen Index Test Apparatus,Accurate fire resistance testing instruments | TestingStandards: ISO4589-2.ASTMD2863.GB/T2406.GB/T5454 Applications: ThisOxygen Index Testerisusedtodeterminethelowestoxygendensitythattestedma... | |

| Helmets Designated Protection Areas Tester | Main Purposes 1. Used to mark test points and test lines on helmets. 2. Used for line - marking according to different test standards. 3. Used t... | |

| Diaper Anti-Side Leakage Performance chamber | Meet the standard: Compliant with GB: GB/T 28004.1 Diapers Part 1: Baby Diapers. GB/T 28004.2-2021 Disposable diapers—Part 2:Disposable dia... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | 卖方: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | 卖方: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | 卖方: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | 卖方: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | 卖方: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |