Safety Helmet Chin-strap Strength Tester

The Safety Helmet Chin-strap Strength Tester is designed to evaluate the tensile strength and reliability of chin straps on industrial, sports, and specialized safety helmets. It ensures compliance with national and international safety standards, supporting quality control, R&D, and certification testing.

Application

(1) Tensile strength testing of industrial safety helmet chin straps

(2) Quality inspection for sports and recreational helmets

(3) Compliance verification for GB/T 2812-2006 and ISO/EN 397

(4) Research and development of helmet safety designs

(5) Batch testing in helmet manufacturing for global certification

(6) Assessment of strap materials and attachment durability

Standards

(1) GB/T 2812-2006 – Safety Helmets

(2) GB/T 2811-2019 – Head Protection Vocabulary and Test Methods

(3) ISO/EN 397 – Industrial Safety Helmets (Equivalent Compliance)

(4) CE Certification (Conformité Européenne)

Features

(1) Motorized Tensile Stage: Adjustable 0–500 mm/min with real-time force-displacement graphing

(2) Dynamic Force Feedback: 0.1 N resolution load cell with peak force memory

(3) Self-Calibrating System: Auto-tare and linearity checks before each test

(4) Modular Head Assembly: Fits adult, child, and custom helmet sizes (50–65 cm circumference)

(5) Quick-Swap Anthropomorphic Mandibles: Facilitates rapid helmet mounting

(6) Durable Construction: Aircraft-grade aluminum frame with corrosion-resistant sensors

(7) User Interface: LED display visualizing force curves during dynamic loading

(8) Safety Systems: Emergency shutoff and overload protection at 2,200 N

Parameters

| Parameter | Specification |

|---|---|

| Force Range | 0–2,000 N (200 kgf capacity) |

| Load Rate | 20 N/min ±2 N/min (adjustable) |

| Max Load Time | 150 N achieved within 60 s |

| Force Resolution | 0.1 N (10 gf) |

| Head Model | Quick-swap anthropomorphic mandible |

| Power Supply | 220V AC, 50/60Hz (single-phase) |

| Dimensions | 600 mm (W) × 450 mm (D) × 1,200 mm (H) |

| Weight | 80 kg (net) |

Accessories

(1) Testing Kit: 2x adult-size head forms (56 cm/58 cm circumference), 5x calibration grade load cells (10 N–2,000 N)

(2) Software Suite: License key for ChinStrapTest Pro (Windows/macOS), 1-year free access to cloud-based tensile analysis tools

(3) Calibration & Safety: NIST-traceable force gauge, 2x safety glasses (EN 166 rated)

(4) Maintenance Kit: Spare drive belts and bearings, machine cleaning solution (non-corrosive)

(5) Documentation: Multilingual quick-start guide (printed + digital), GB/T/ISO compliance certificates

Test Procedures

(1) Mount helmet onto anthropomorphic mandible.

(2) Secure chin strap in clamp fixtures.

(3) Set load rate and test parameters via touchscreen interface.

(4) Start tensile test; monitor force-displacement curve in real time.

(5) Record peak force and evaluate strap performance against standards.

(6) Export test report for QC or certification purposes.

Maintenance Information

(1) Inspect mandibles, clamps, and load cells regularly for wear or damage.

(2) Clean frame and fixtures with non-corrosive solution.

(3) Verify calibration of force measurement system periodically.

(4) Lubricate moving parts according to maintenance schedule.

(5) Store in dry environment to maintain precision and extend service life.

在线联系供应商

Other supplier products

| Safety Helmet Chin-strap Strength Tester | Standard GB/T 2812-2006: Safety Helmets GB/T 2811-2019: Head Protection – Vocabulary and Test Methods Equivalent Compliance: ISO/EN 397 (I... | |

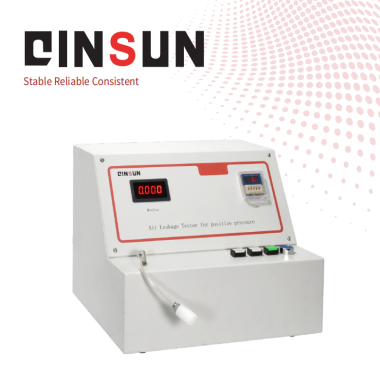

| Infusion Apparatus Leakage Positive Pressure Tester | The M102 Infusion Apparatus Leakage Positive Pressure Tester is designed to evaluate the airtightness and sealing performance of medical injection ... | |

| Carpet Pilling and Fuzzing Tester | Instrument Description This instrument is used to simulate the pilling and fuzzing phenomena that occur during the normal use of carpets. The inst... | |

| Pinhole Tester | The pinhole tester for aluminum foil is a device specifically used to detect micro - pinholes in aluminum foil materials. The following is a detail... | |

| Dental Implants Fatigue Tester | Standard ISO 14801:2016: Specifies dynamic fatigue testing protocols for endosseous dental implants, including load ratios, frequency, and failure... |

Same products

| Thrust Bearing Rolling Friction and Wear Testing Machine | 卖方: Standard International Group (HK) Limited | Applicable Standards: ASTM D3702 ASTM G99 ASTM G77 ISO 18535 Product Advantages: Simulates ... | |

| Falling Sand Abrasion Test machine | 卖方: Standard International Group (HK) Limited | The sand abrasion tester is a specialized testing device used to evaluate the abrasion resistance... | |

| Conveyor Belt Drum Friction Testing Machine | 卖方: Standard International Group (HK) Limited | Main Purposes of Conveyor Belt Drum Friction Testing Machine The conveyor belt drum friction tes... | |

| Dry Sand Rubber Wheel Wear Tester | 卖方: Standard International Group (HK) Limited | The dry sand rubber wheel abrasion tester is mainly used to test the abrasion resistance of mater... | |

| Sliding Bearing Fatigue Testing Machine | 卖方: Standard International Group (HK) Limited | The sliding bearing fatigue testing machine is an important testing device, mainly used to evalua... |