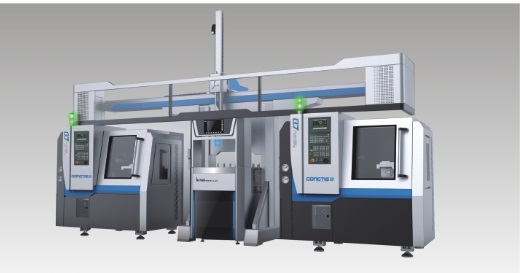

CNC lathe with picking woking pieces

CNC lathe with picking woking pieces

CNC lathe with tray device

cnc lathe with tray device manufacturer

Q series-precise linear guide-way with flat bed in blade row : Q5,Q7,Q5C,Q7C

Sseries-precise linear guide-way with flat bed in blade row :S36, S350

with the features of high precision. high speed. high efficiency, is the ideal selection for substituting hard rail lathes and imported lathes.

* High precision: importing components from Japan and Taiwan through the advanced assembly and inspection technology, realizing the precise turning with tolerance of μ level.

* High speed: more than 5000RPM for spindle ,rapid traverse 20m/s, toreach the high speed machining.

*High-efficiency: with the concept of technique innovation and application oriented, and sustainabilityimprovethe overall performance, to make the processing more efficiency.

* Stability: high quality requirement and strict selecting for all thecomponents, to make the machine performance more stable.

(Synchronous electric spindle)- the best selection for substituting the imported lathes.

* More precision: the complete Synchronous servo configuration for the spindle and the X/Z axis, makes the processing accuracy get a new break through.

* Higher speed: the superior Synchronous electric spindle make the spindle perform higher, faster, and more stable.

* More efficiency: the complete, Synchronous control for the core parts (all the axis),makes the processing efficiency better.

Inthis technical solution,we use one gantry loader plus another tray device to realize automatic processing & picking woking pieces. It is more suitable for disk type parts.

|

Mainparameters |

UNIT |

Q5 |

Q7 |

Q7C |

S36 |

S36C |

S350 |

S36D |

S350D |

||

|

Capability |

mm |

245 |

285 |

285 |

300 |

300 |

350 |

300 |

350 |

||

|

mm |

240 |

270 |

270 |

270 |

270 |

350 |

270 |

350 |

|||

|

mm |

200 |

300 |

300 |

330 |

330 |

420 |

330 |

420 |

|||

|

mm |

21(25) |

26(35) |

26(35) |

26(35) |

26(35) |

40 |

26(35) |

40 |

|||

|

AxisStroke |

X-axistravel |

mm |

250 |

320 |

320 |

420 |

420 |

420 |

330 |

330 |

|

|

Z-axistravel |

mm |

200 |

300 |

300 |

330 |

330 |

330 |

420 |

420 |

||

|

RapidTraverse |

X/Z-axis |

m/min |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

|

|

Spindle |

Spindlenosesize |

N/A |

A2-4 |

A2-5 |

A2-4 |

A2-5 |

A2-5 |

A2-5 |

A2-5 |

A2-5 |

|

|

Spindleservomotorpower |

kW |

synchronouselectricspindle3.7/5.5 |

|||||||||

|

Spindlespeedrange |

rpm |

0~5500 |

0~5000 |

0~6000 |

0~5000 |

0~5000 |

0~4500 |

0~5000 |

0~4500 |

||

|

Workpiececlampingmethod |

N/A |

25collet4'hydraulicchuck |

36collet(5'hydraulicchuck) |

36collet(5'hydraulicchuck) |

36collet(5'hydraulicchuck) |

36collet(5'hydraulicchuck) |

6'hydraulicchuck42collet |

36collet(5'hydraulicchuck) |

6'hydraulicchuck(42collet) |

||

|

Numberoftools |

PCS |

5 |

5 |

7 |

5 |

5 |

5 |

3+8 |

3+8 |

||

|

Toolholder |

Toolholdertype |

N/A |

Dovetailrowofknives |

Dovetailrowofknives |

Dovetailrowofknives;bladerow+spindlehead |

T-slotbladerow+spindlehead |

T-slotbladerow+spindlehead |

T-slotbladerow+spindlehead |

T-slotbladerow+63turret+spindlehead |

T-slotbladerow+63turret+spindlehead |

|

|

Toolholdercenterheightinradial |

mm |

50 |

50 |

50 |

62 |

62 |

62 |

62 |

62 |

||

|

Toolsize |

mm |

16*16 |

16*16 |

16*16 |

20*20 |

20*20 |

20*20(25*25) |

20*20 |

20*20(25*25) |

||

|

Boringroddiameter |

mm |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

||

|

Accuracy |

XZaxisrepeatingpostioningaccuracy |

mm |

|||||||||

|

Others |

Coolingmotorcapacity |

L |

120 |

120 |

120 |

120 |

120 |

120 |

120 |

120 |

|

|

hydraulicboxcapacity |

L |

60 |

60 |

60 |

60 |

60 |

60 |

60 |

60 |

||

|

Requiredelectricpower |

kVA |

7 |

8 |

8 |

12 |

12 |

14 |

15 |

15 |

||

|

Heightfromfloortospindlecenter |

mm |

≈1050 |

≈1070 |

≈1070 |

≈1070 |

≈1070 |

≈1070 |

≈1000 |

≈1000 |

||

|

Overallsize(L*W*H) |

mm |

1500*1250*1650 |

1650*1300*1650 |

1650*1300*1650 |

1850*1750*1750 |

1850*1750*1750 |

1850*1750*1750 |

1850*1750*1750 |

1850*1750*1750 |

||

|

Netweight |

kg |

≈1200 |

≈1700 |

≈1700 |

≈2400 |

≈2400 |

≈2400 |

≈2600 |

≈2600 |

||

|

Standardconfiguration:Toolbox,instructionbook,operationalmanual,coolingsystem,lightingsystem,lubricationsystem,chipscleaner,hydrauliccollet(chuck),footswitch |

|||||||||||

|

Optionalconfiguration:programcontrolblowingfunction,precisionCaxisdividing,powerspindlehead,automaticdoor,loadingandunloadingsystem,industrialrobotic,automaticbarfeeder,receivingdeviceforbarmaterials,automaticdetectionsystem,automaticcutterradiuscompensationsystem,high-pressurecoolingsystem |

|||||||||||

在线联系供应商

Other supplier products

| CNC machine with slant bed | CNC machine with slant bed CNC machine with rotary pallets CNC machine with transfer belt The proposed CNC machine: S36/S350/S400 with slant bed Ro... | |

| Electric Spindle Cnc Lathe | Electric Spindle Cnc Lathe Q series-precise linear guide-way with flat bed in blade row : Q5,Q7,Q5C,Q7C * High precision: importing components ... | |

| slant bed lathe with programmable blowing | slant bed lathe with programmable blowing OEM slant bed lathe,cnc lathe with Slant Bed price Sseries-precise linear guide-way with flat bed in bl... | |

| Double Lathes with Gantry Loader | Double Lathes with Gantry Loader Q series-precise linear guide-way with flat bed in blade row : Q5,Q7,Q5C,Q7C S series-precise linear guide-way wit... | |

| precision cnc lathe Turning Center | precision cnc lathe Turning Center cnc lathe turning center machine M series-precise linear guide-way turning center with 5 axis is a new high-end ... |