Hi-chrome Carbide Wear Parts

Hi-chrome Carbide Wear Parts

OVERLAY-PLATE is welded by chrome carbide overlay on a mild steel backing plate.

Manufactured by our own design's precision fabrication and welding machine with exclusive technique. OVERLAY-PLATE has excellent performance in abrasion resistant.

Benefits of Hi-chrome Carbide Wear Parts

HARDNESS AVAILABLE 55-58HRC, 58-62HRC, 62-65HRC

TOLERANCES ± 1mm

HEAT RESISTANCE Maximum: 450˚C

MICROSTRUCTURE Mixture of high volume hexagonal shaped chromium carbide in tough austenitic and martensitic. Average VFC above 30%.

CUTTING Plasma (from backing plate side) / Laser Cutting Fabrication/ Water Jet Knife

PENETRATION TO THE BASE METAL 1.5mm

COLD FORMING Minimum Radius: 150mm (for 6+4)

Suggested: using hydraulic press to bend plate

Why Choose WALKSON Hi Chrome Casting Carbide Wear Parts

APPLICATIONS -Ash liners -Elbow -Sinner plant -Bucket & Lips -Drag liners -Duct -Classifier -Mine car liners -Grinding Mill Liners-Cyclones -Ore chutes -Discharge funnels -Slag chutes -Extension ring -Cement kilns -Grizzly bars -Sinter breaker bar -Conveyor casings -Green Walt crushers -Steel plant -Blast furnace bell & burden -Chute & Hopper liners -Fan blades & Housings -Dredge pump side plates -Vibrator pan feeder liner

Low cost

High wear resistant property

Good forming ability

If you want to find a reliable steel foundry china, please choose us, and we will be your best partner.

We can also offer kinds of undercarriage components for sale, if you are interested, please contact us.

Other supplier products

|

|

Safety Valve |

WALKSON, as a professional safety valve casting manufacturer, supplies main parts for pressure safety valve, consisting of Valve Body, Disc, Stem a... |

|

|

Check Valve |

As a professional high pressure check valve part manufacturer, Walkson provides castings or forgings for adjustable cracking back check valves.

... |

|

|

Bimetallic Wear Plates |

Bimetal steel plateare unique wear resistant materials in that they combine very high wear resistant qualities of a white iron (ASTM A532 15%CrMo, ... |

|

|

Hot Forging |

Hot forging is also called hot die forgingby hot forging manufacturers. During the hot die forging process, the deformed metal flows violently and ... |

|

|

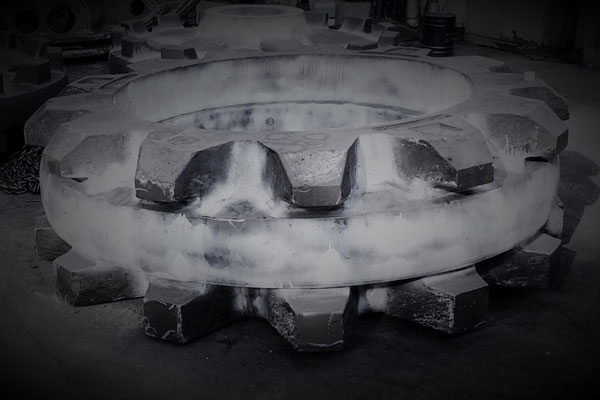

Sprocket/ Tumbler |

The sprocketis made from low alloy high strength steel, combined with quenched and tempered heat treatment plus induction hardened to get the requi... |

供应产品

Same products