Titanium carbide hard rods support small-batch trial use

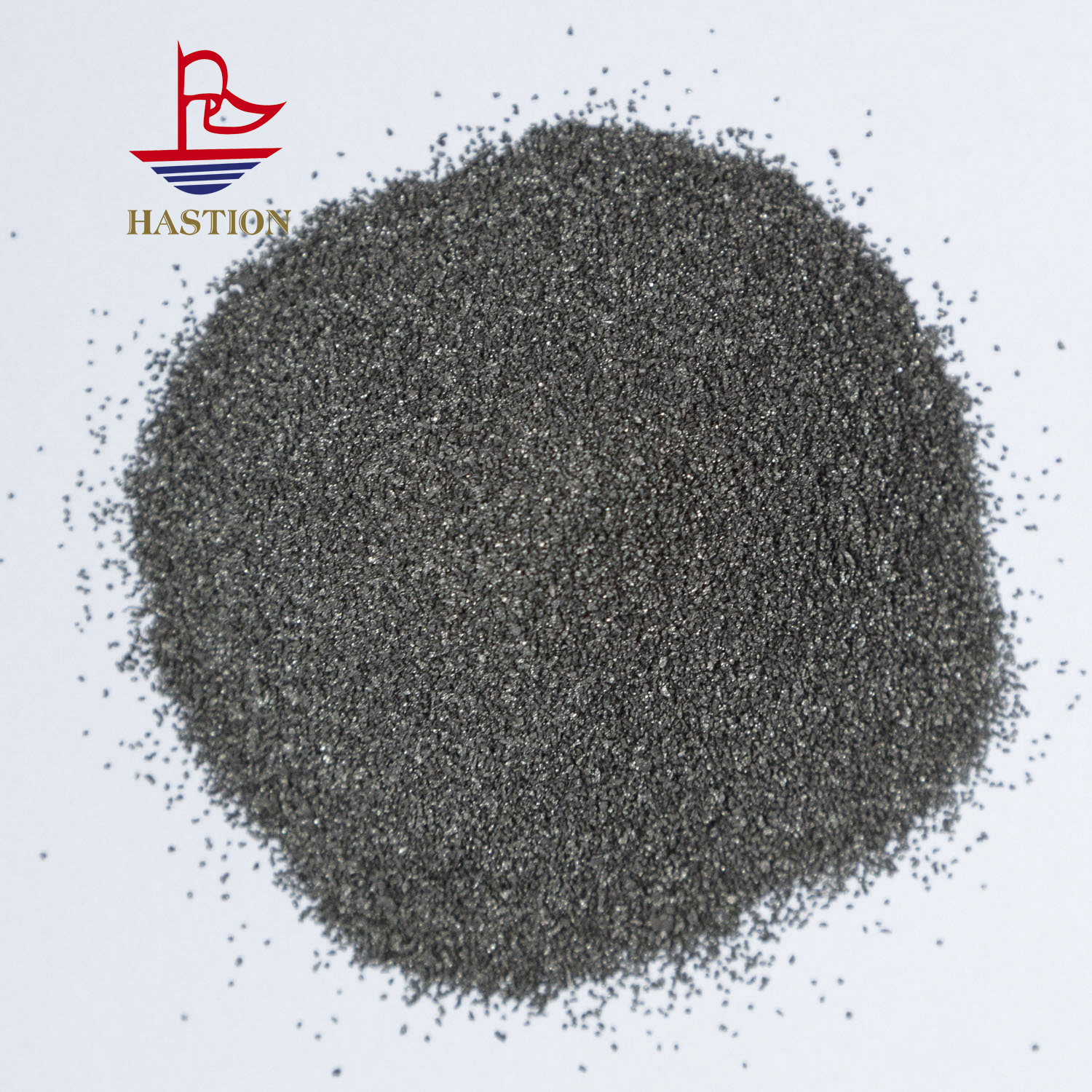

Titanium carbide (TiC) round rods fabricated from tungsten carbide-based cemented carbides exhibit exceptional anti-adhesion properties. During machining of highly adhesive materials—such as aluminum and copper alloys—the incidence of built-up edge (BUE) formation and tool–workpiece adhesion is significantly reduced, thereby enabling stable cutting conditions and achieving superior surface finish integrity. Surface performance—including wear resistance and high-temperature oxidation resistance—can be further enhanced via advanced physical vapor deposition (PVD) coatings (e.g., TiAlN), extending tool service life by over 50% relative to uncoated counterparts. In the medical device sector, these rods are precision-machined into orthopedic surgical instruments, where they maintain dimensional stability and edge retention under repeated autoclaving cycles (up to 134 °C), ensuring both functional sharpness and long-term sterility compliance. Leveraging advancements in additive manufacturing, TiC-reinforced tungsten carbide powders—derived from comminuted rod stock—are now employed in laser powder bed fusion (LPBF) processes to fabricate near-net-shape components; sintered-equivalent density (>99.5% of theoretical density) and mechanical performance comparable to conventionally sintered parts have been consistently achieved. In photovoltaic manufacturing, TiC-based cutting tools are utilized for silicon wafer slicing, enabling tight control of kerf loss and thickness tolerance within ±1 μm—thereby minimizing material waste and enhancing solar cell conversion efficiency. Owing to this broad spectrum of high-performance attributes across diverse industrial domains, titanium carbide–enhanced cemented carbide constitutes a critical enabling material for advanced manufacturing applications.

Other supplier products

供应产品

Same products