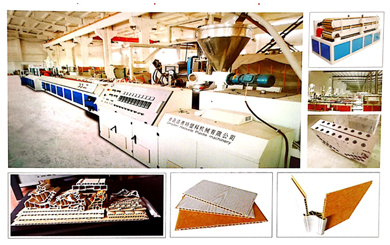

PVC Three-Laver Synthetic Resin Tile Production Line

The structure and working principle of Three-layer synthetic resin

The unit is composed of frame parts, traction and forming machine, automatic cutting machine, discharge shelf, electrical control box and others.

Characteristics ofThree-Laver Synthetic PVC Resin TileProduction Line

Volume stability-the expansion factor of synthetic resin tile is 49310-5mm / mm / C , and the waveform has bi-directional tensile property geometrically, even the temperature changes too much , the expansion of the tile can also be digested by itself , to ensure the size no change, strong fire resistance-the main material of synthetic resin tile is PVC , belongs to non-flammable , through the state fire department testing fire performance Insulation - The synthetic resin tile is insulating material , it will be intact even accidental discharge lightweight - The synthetic resin tile belongs to light structure material , weight ( 5.6 + 0.2 ) Kg / 0Clean and saving-the synthetic resin tile itself is smooth and compact , which is not easy to absorb dust .o . . Easy installation-the synthetic resin tile is lightweight and various accessories, so it easy to loading and unloading : in addition , the effective width of synthetic in tile is 960mm , the efficiency is higher than width 720mm synthetic resin tile , can save more cost.

Performance & Advantages of PVC Three-Laver Synthetic Resin Tile Production Line

It has a reasonable structure, strong bearing capacity and good rigidity. It is used for carrying and fixing all the mechanisms A pneumatic control box is installed on the rack of the fixing tractor and cutting machine to control various actions in the production process

The mechanism consists of a pair of corrugated upper and lower formwork to form the shape of the product. The upper and lower form-work is provided with an air cooling system. By cooling the formed products, the formed waveform is no longer deformed due to high temperature. The opening and closing of the upper template is accomplished by a pair of lifting cylinders fastening the lower template Operate the manual control valve of traction lifting to make the upper plate open and close freely There are adjustment bolts at the bottom of the lower plate , and the height of the lower plate can be adjusted according to the process needs to ensure the required center height for normal production traction mechanism : to obtain the normal production tension required to synchronize the extrusion speed with the traction speed The mechanism adopts advanced frequency control technology and chain sprocket and gear rotating system Adopting step-less speed regulation , it has the advantages of wide speed regulation range , stable and reliable transmission and strong overload capacity The working process is : three-phase ac motor , which is transmitted to two-stage cycloid pin-wheel reducer after adjusting speed by frequency converter ,d then to upper and lower traction templates through a pair of double-row sprocket wheels.

To finish the cutting of product based on any length, to make the products leave the cutting machine, to ensure next cutting successfully. The mechanism has the advantages of accurate length, smooth cut and timely feeding The concrete consists of sliding shear table.

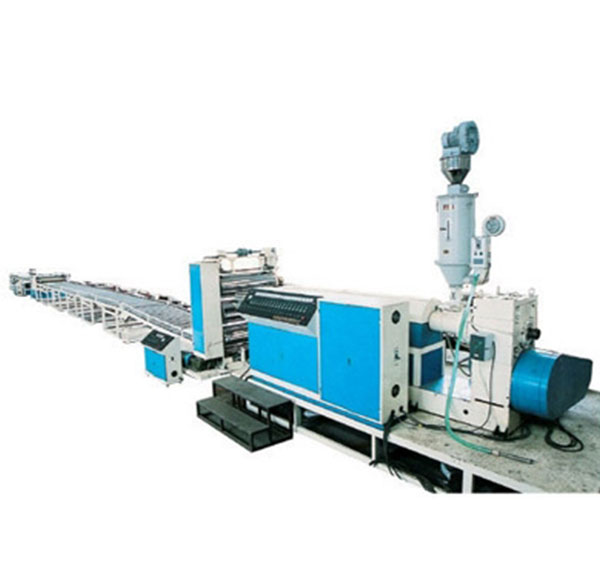

The Kailitemain products include plastic machinery series: extruder, plastic pipe production line, plastic sheet/sheet equipment, plastic profile production line, wood-plastic equipment, plastic recycling granulator, plastic crusher, etc.

在线联系供应商

Other supplier products

| HDPE Water And Gas Pipe Production Line | Features & Advantages: The Large Diameter HDPE/MDPE Pipe Extrusion Line research & developed by Jwell Machinery Co., features of unique str... | |

| Wood Plastic Extrusion Line | Our company develop this wood plastic extrusion linewhich is fully mixed with raw materials such as PVC, PP, PE and other plastics and plant fibres... | |

| PET PP Waterstop Production line | Performance & Advantages Accurate dosing and raw material blending Preheat and dry circulating automatically Even plasticization, stable extrus... | |

| PP Hollow Plastic Building Board Production Line | Our company specialized in manufacturing PP hollow building board production, and provides full production equipment for many enterprises at home a... | |

| PP Plastic Sheet/Board Production Line | PE PP Plastic Sheet/Board extruding production line is a is mainly used in the products of PE or PP thicker plastic sheet/board. Product thickness... |

Same products

| Clear PVC Tee | 卖方: Suzhou Verygreen New Material Co.,LTD | VERYGREEN can offer high-quality Clear PVC Tees to meet your different needs. The translucent ... | |

| Clear PVC Pipe | 卖方: Suzhou Verygreen New Material Co.,LTD | Transparent Plastic Pipe Tube PVC, Clear Transparent Rigid PVC PipeTube Price Clear PVC pipes, c... | |

| Clear Transparent PVC Pipe Fittings | 卖方: Suzhou Verygreen New Material Co.,LTD | Transparent pipe fittingsare used with the transparent pipe, which ensures the whole pipeline sys... | |

| Clear PVC Elbow | 卖方: Suzhou Verygreen New Material Co.,LTD | VERYGREEN can offer high-quality Clear PVC Elbows to meet your different needs. Clear acrylic ... | |

| Clear PVC Coupler | 卖方: Suzhou Verygreen New Material Co.,LTD | VERYGREEN can offer high-quality Clear PVC Couplers to meet your different needs. Clear PVC co... |