4/5 AXIS CNC MACHINING

4 axis cnc machining

4 axis cnc machine price

4 axis cnc machine for sale

4 axis cnc machining manufacturer

5 axis cnc cost

cnc axis types

5 axis processing

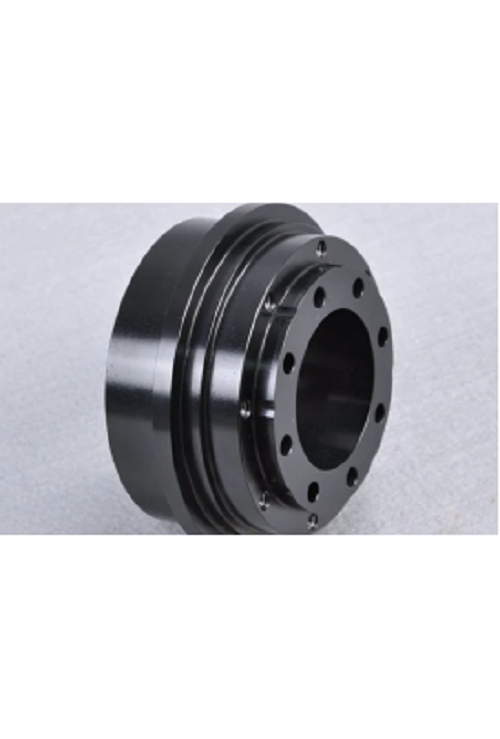

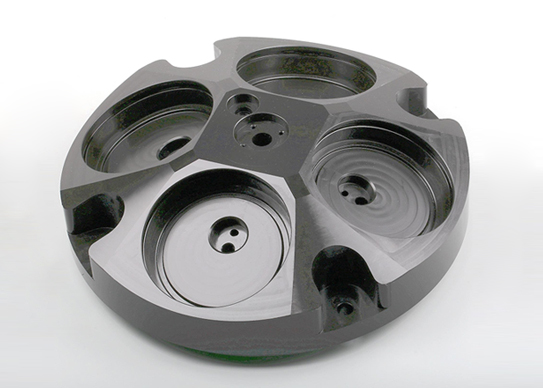

We have 5 sets of 4-axis machining centers, 10 sets of 5-axis machining centers, providing an annual processing capacity of 100000 pieces. China 4 axis cnc machining, five axis CNC, processing parts from all kinds of screws, propellers (fan blades), precision gears and other complex products that need to be continuously positioned without replacing parts, especially large complex shapes parts.

What is 4/5 Axis CNC machining?

4-axis CNC machining center and china 5 axis cnc machiningcenter: the 4-axis CNC machining center is defined by adding a rotation axis to the traditional CNC machining center (3-axis). The rotation axis is composed of 4 axes by selecting any one of axis A, axis B, and axis C. The affordable 5 axis cncmachining center is composed of two axes selected from three axes.

4/5 Axis CNC machining Design Guideline

4Axis CNC Milling

The China 4 axis CNC machining processing capabilities and scope that our company can provide are as follows:

|

Material |

copper, aluminum, iron, plastic, alloy, etc |

||||

|

item |

unit |

MODEL:50A |

MODEL:63A |

MODEL:80A |

|

|

Stroke |

X-axis |

MM |

720 |

1,000 |

1,200 |

|

Y-axis |

MM |

700 |

800 |

950 |

|

|

Z-axis |

MM |

650 |

900 |

900 |

|

|

Table |

Pallet dimensions |

mm |

500x500 |

630x630 |

800x800 |

|

Maximum loading mass |

Kg |

800 |

1,200 |

1,600 |

|

|

Spindle |

taper |

ISO 7/24 Taper NO.40 |

ISO 7/24 Taper NO.50 |

ISO 7/24 Taper NO.50 |

|

|

Spindle speed |

min-1 |

8,000(OP:12,00/20,000) |

6,000(OP:12,000/20,000) |

6,000(OP:12,000/20,000) |

|

|

Feed rate |

Fast forward speed |

m/min |

36 |

54 |

24 |

|

Cutting feed rate(Max) |

m/min |

20 |

32 |

10 |

|

|

APC |

2APC front swivel type |

2APC front swivel type |

2APC front swivel type |

||

|

ATC |

Number of tools stored |

BOOK |

60 |

60 |

60 |

|

Machine Mass |

Kg |

About 12,000 |

About 18,000 |

About 20,000 |

|

5Axis CNC Milling

The 5Axis CNC Milling processing capabilities and scope that our company can provide are as follows:

|

Material |

copper, aluminum, iron, plastic, alloy, etc |

||||

|

item |

unit |

MODEL:50A |

MODEL:63A |

MODEL:80A |

|

|

Stroke |

X-axis |

MM |

720 |

900 |

1,200 |

|

Y-axis |

MM |

850 |

900 |

1,000 |

|

|

Z-axis |

MM |

850 |

900 |

1,050 |

|

|

A-axis |

- |

-90 |

-90 |

-90 |

|

|

B-axis |

- |

360 |

360 |

360 |

|

|

Table |

Pallet dimensions |

mm |

500x500 |

630x630 |

800x800 |

|

Maximum work size(Diameter x height) |

mm |

Φ750x700 |

Φ950x900 |

Φ1,200x1,000 |

|

|

Maximum loading mass |

Kg |

650 |

700 |

1,200 |

|

|

Spindle |

taper |

ISO 7/24 Taper NO.50 |

ISO 7/24 Taper NO.50 |

ISO 7/24 Taper NO.50 |

|

|

Spindle speed |

min-1 |

12,000(OP:20,000) |

6,000(OP:12,000/20,000) |

12,000(OP:20,000) |

|

|

Fast forward speed |

XYZ axes |

m/min |

X:24 YZ:36 |

X:12 YZ:24 |

X:24 YZ:24 |

|

A-axis |

min-1 |

6 |

6 |

6 |

|

|

B-axis |

min-1 |

12 |

10 |

10 |

|

|

APC |

2APC front shuttle (OP:6/8/10) |

2APC front shuttle (OP:6/8/10) |

2APC front shuttle (OP:6/8/10) |

||

|

ATC |

Number of tools stored |

BOOK |

60 |

60 |

60 |

|

Machine Mass |

Kg |

About 18,000 |

About 25,000 |

About 30,000 |

|

What is the Difference Between 4/5 Axis CNC machining

Compared with the ordinary CNC machining center (three-axis), the four-axis increases the angular rotation of parts, and the five-axis increases the functions of angular rotation of parts and angular rotation of tools (both slow linkage), so that the ordinary shenzhen cnc machiningmachine tool has the function of machining more complex parts. The main difference between them is that the complexity of processing parts is different. The range of five-axis processing is wider than that of four-axis processing. At the same time, the cost of five-axis processing is also higher. Generally, it is more suitable for use in the product sample stage. Five-axis processing includes Aeroengine Blades, shells, automobile, and shipbuilding industries. 5 axis CNC serviceis usually very suitable for extremely complex and strong parts that must be cast, such as parts with high relative accuracy and parts that cannot be clamped twice. Four-axis machining parts are usually parts that cannot be machined by ordinary three-axis CNC, such as turbine, vortex rod, fan blade, wave wheel, and other curved surface and groove machining.

Applications of 4/5 Axis CNC machining

The 4axis CNC center can adapt to the parts processing in the mold industry, automobile parts and wheel hub processing, automatic machining, and 4 axis machining is also widely used in aerospace and other fields. Industrial upgrading, intelligent manufacturing, unmanned factory and automatic assembly line are the most direct requirements of the processing and manufacturing industry for high-end machining machines. The application scenarios of four-axis and five-axis CNC processing are as follows:

Aerospace industry: from Boeing 787 Aircraft propeller parts (titanium alloy or polymer materials), turbocharger (metal) parts, gearbox shell processing (casting), hydraulic system and component processing (casting), electromechanical component parts (metal), engine component processing (metal), landing gear assembly (integrated molding), UAV components (carbon fiber shell, propeller), etc. of Airbus A380 large aircraft.

Medical industry: bone plate processing (titanium TA2, etc.), medical bone contusion parts (pure titanium TA2) customization, implantable medical device parts processing, surgical robot, surgical instrument, surgical robot body, medical device parts processing, etc.

Automobile industry: such as engine block (casting), lamp reverse bowl (injection molded part), gearbox shell (casting), turbocharger assembly (casting), automobile valve, automobile brake system assembly, suspension pin and arm, transmission shaft, hydraulic connector and bushing, valve, pump body, etc.

Robot automation industry: such as robot reducer, robot joint, robot arm, exoskeleton wearable robot parts customization, quadruped robot parts CNC processing, etc.

Advantages of 4/5AXIS CNC Machining

The advantages of 4-axis and 5-axis linkage machining center compared with ordinary 3-axis machining center are mainly reflected in the following points:

01

The available tools have been greatly expanded. 4-axis and 5-axis machine tools can use more processing tools at one time: turning tool, milling cutter, boring cutter, drill bit, spherical cutter, etc. China 4 axis cnc machining and five axis machiningmake the processing technology choose more.

02

More processing technologies make the clamping time shorter and less: one-time clamping can complete more processing procedures, making it possible not to need secondary clamping. Greatly reduce the quality problems of parts caused by secondary clamping.

03

No fixture (customized fixture): all processes are completed in one clamping, and there is no need to customize the clamping fixture due to the needs of processing technology. Directly reduce cost and time.

04

Greatly improve the surface processing quality of parts: one-time clamping can avoid the error caused by repeated positioning, improve the surface processing accuracy, multi-process uninterrupted processing, and the positions that cannot be processed by ordinary machine tools can be completed at one time, which will improve the surface quality of parts (smoothness, integrity, accuracy, etc.).

05

Extend the comprehensive life of the tool: the free choice of multiple processes makes the tool make the best use of everything, and there is no need for the milling cutter to waste time completing the boring process, which makes the wear position of each kind of cutter fixed and convenient for subsequent work such as inspection and maintenance, which directly improves the service life of the tool.

06

Improve production concentration: a machine can complete the functions and work of a lathe, milling machine, boring machine, drilling machine and other machine tools at one time, which greatly improves the production concentration.

07

Improve processing production and enterprise efficiency: To sum up, the quality of parts processed by 4-axis and 5-axis machine tools is guaranteed, reducing processing loss, improving concentration and facilitating enterprise management. Directly reduce processing costs and improve enterprise efficiency.

4-axis CNC machining center and 5-axis CNC machining center: the 4-axis CNC machining center is defined by adding a rotation axis to the traditional CNC machining center (3-axis). The rotation axis is composed of 4 axes by selecting any one of axis A, axis B, and axis C. The five-axis CNC machining center is composed of two axes selected from three axes.

As a 4 axis cnc machining manufacturer, we will do our best to meet all the needs of customers.

Send product request

Other supplier products

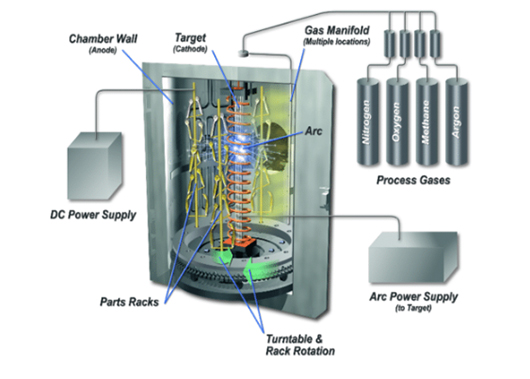

| SURFACE FINISHING | The surface texture treatment requirements of special industries are extremely stringent, such as parts and products in extreme climatic environmen... | |

| ELECTRONICS CNC MACHINING | ELECTRONICS CNC MACHINING Our purpose is to provide customers with processing services of various testing fixtures, mold parts and non-calibrated ... | |

| CHINA 4-AXIS & 5-AXIS CNC MACHINING | As a leading China 4 &5 axis CNC machining manufacturer, Richconn understand the importance of offering cutting-edge technologies to meet diver... | |

| Black Oxide Services | At Richconn, we rely on rack and suspend technology to provide black oxide coating services that are delivered quickly and meet high quality standa... | |

| POWDER COATING | POWDER COATING The atomized paint is sprayed on the metal surface and solidified after high-temperature baking to form the effects of anti-corrosi... |

Same products

| What Are The Characteristics Of CNC Machining? | Seller: shenzhen richconn technology co.,ltd | What Are The Characteristics Of CNC Machine? Process concentration, automation, high flexibili... | |

| PVD COATING | Seller: shenzhen richconn technology co.,ltd | Physical vapour deposition, just PVD coating, as we usually call it, refers to vacuum ion plating... | |

| ELECTROPHORESIS COATING | Seller: shenzhen richconn technology co.,ltd | Electrophoresis metal coatingcan be called electrocoating, e-coating, electrophoretic painting, a... | |

| CNC PLASTIC MACHINING | Seller: shenzhen richconn technology co.,ltd | The characteristics of plastic cnc machining chinamaterial are defined by the melting point tempe... | |

| CNC MACHINING MATERIALS | Seller: shenzhen richconn technology co.,ltd | CNC machining has not too many restrictions on CNC material list. Common plastics, metals, or spe... |