Electronics Product Mould

Electronics Product Mould

Decades of accumulation of mould manufacturing technology have witnessed the popularity of electrical plastic molding products.

The electronics custom plastic injection moldhas been widely applied to various industries. As a result, electronics injection mold manufacturers have been talking about rapid prototype plastic molding that will change electronic devices.

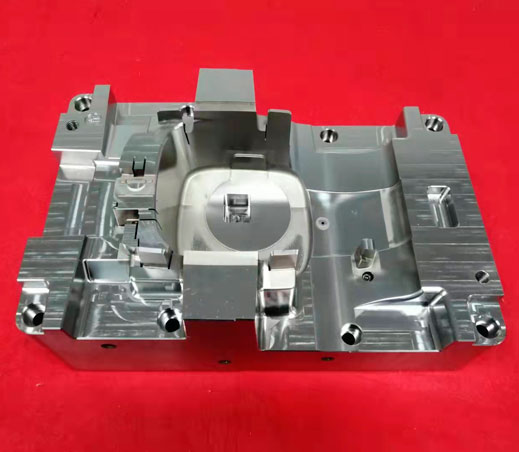

Features of Electronics Product Mould

Since the popularity of electrical plastic molding products, why do people choose suchprecision plastic mold technology? Here are some major features of in mould electronics.

Reduction in the complexity of plastic products;

Automation of assembly processes;

Integration of electronics into products that have geometrically complex3d printingshapes;

Reduction in thickness and weight;

Increased functionality;

More durable electronics can be manufactured.

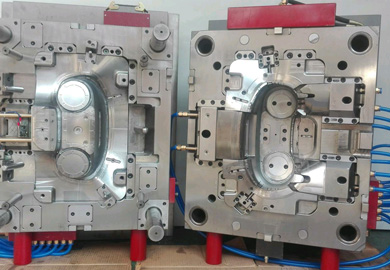

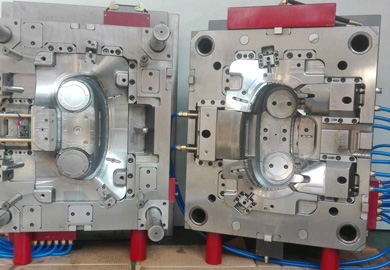

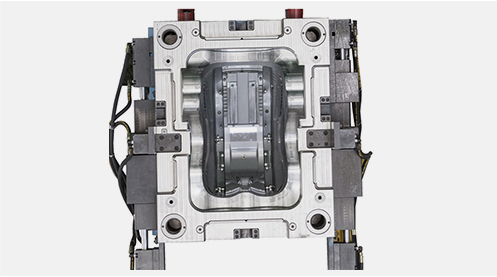

The Specification of Automotive Product Mould

|

Part material |

ABS |

|

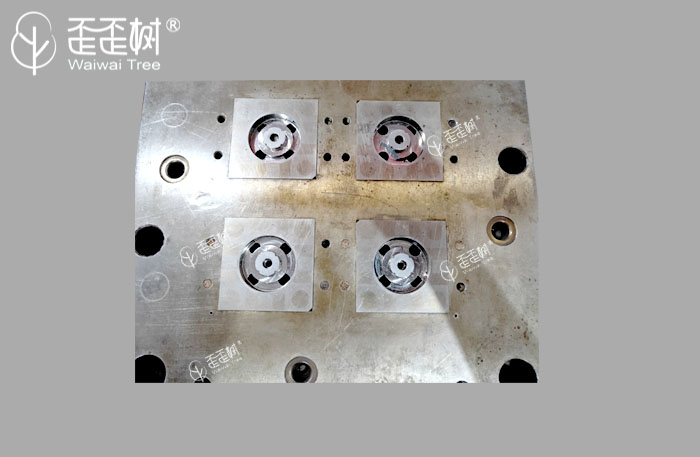

Cavity |

1 |

|

Mould accuracy |

+ / - 0.02 |

|

Mould steel |

|

|

Mouldbase steel |

|

|

Mould life |

100W |

|

Mould standard |

HASCO |

|

Mould structure |

2 slides |

|

Exporting country |

UK |

|

Leadtime |

6 weeks |

|

Mould quality customer satisfaction |

98% |

|

FAI pass rate |

96% |

|

Project cooperation service customer satisfaction |

98% |

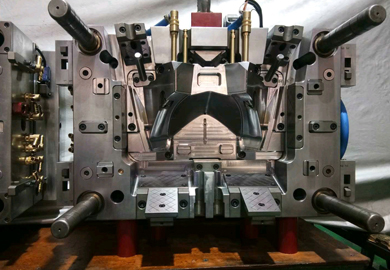

How does Electronics Product Mould Work?

The desired pattern of plastic insert molding is finished through the screen or digital printing in the beginning. Then it is placed in a mold tool. After that, drying polymer pellets are poured into an electrical plastic molding machine. They are melted and pressurized into the mold. The form of plastic injection molding product is filled with polymer, and the printed label is "glued" to the plastic enclosure. At the output, when we open the mold, we get a ready-made part of the plastic enclosure with integrated graphics.

Send product request

Other supplier products

| Die Casting Mould | Die Casting Mould Die casting mould is a method of casting liquid die forging. It is a process completed in a special die casting moulding machine... | |

| 2K Mould | 2k injection mouldingis a manufacturing process that refers to molding two materials or colors into one plastic part. This technology combines t... | |

| Mould Component | Mould Component Mould Componentsare also a part of the mould. GM-TECH not only produces precision moulds but also provides customers with high-pre... | |

| Mould Design | GM-TECH have a much experienced design team, familiar with China domestic, European, American, Japanese and other mold design standards, be able to... | |

| Injection Moulding Products | Injection Moulding Products GM-TECH has been manufacturing tools for injection molding of plastics for various industries for more than 10 years. ... |

Same products

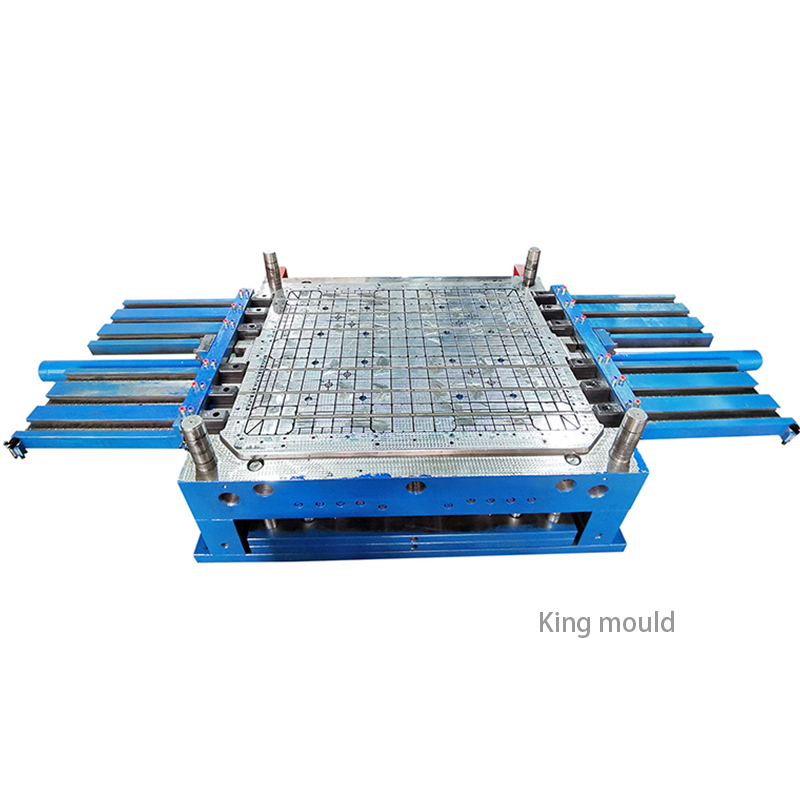

| Plastic Injection Lightweight Pallet Mould | Seller: Zhejiang Huaqi Information Technology Co., LTD | Discover the Pallet Mould, a game-changer in the world of logistics and material handling. Our Pa... | |

| Flange Molding | Seller: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | Flange Molding Flanged joint is the main connection method in pipeline construction. Compared to... | |

| Injection Mold Manufacturing | Seller: HANKING MOULD ENGINEERING LTD. | HanKing Mouldhas the advantages of low labor cost, short mold manufacturing lead time, excellent ... | |

| Car Seat Mould for Kids | Seller: Green Vitality Industry Co., Limited | Child safety seats are seats specially designed to protect children from injury or death in a col... | |

| Industrial Plastic Injection Mold | Seller: Green Vitality Industry Co., Limited | The injection molding part is replacing metal products in many fields of industrial applications ... |