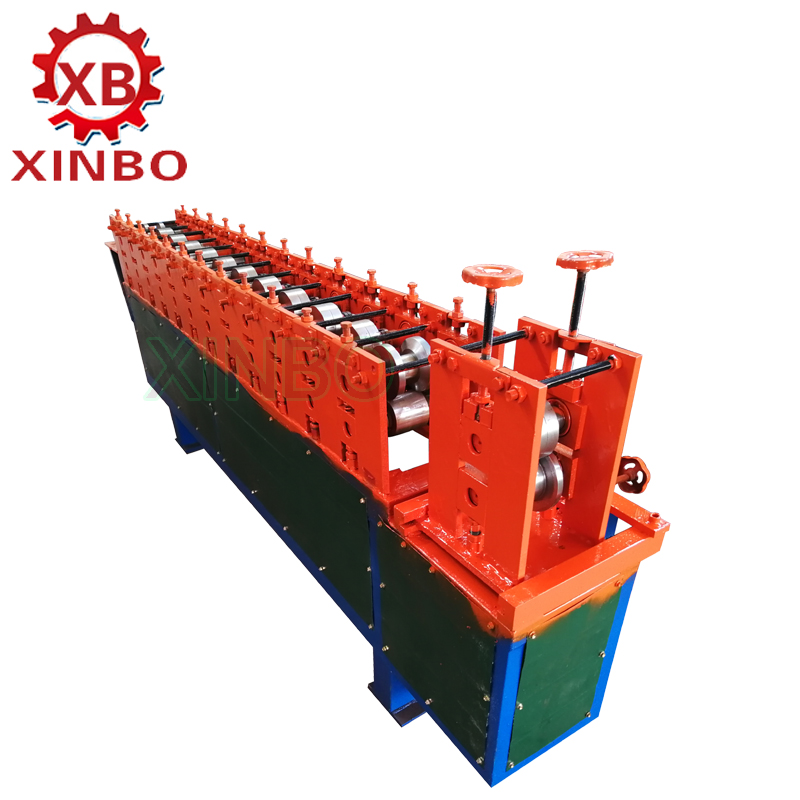

rolling door making machine

rolling door making machine

Shutter door making machine

roller shutter door roll forming machine,automatic rolling door making machine

Product Application:

This Iron Steel Rolling Shutter Door Slats Roll Forming Machine Prices line uses galvanized steel sheet, colored armor plate or aluminum plate as the material plate. The products produced by this Iron Steel Rolling Shutter Door Slats Roll Forming Machine Prices are bright in colored, against fading, resistant to rust, and be widely used in shops, working departments, warehouses, and fire partition. Its strength is three times higher than aluminum alloy door.

Technological process:

Uncoiler-Feeding-Leveling-hydraulic punching-Hydraulic cutting-Roll forming-Output table

Technical parameter:

|

Colorsteelsheet,galvanizedsteelsheet,aluminum sheet |

|

|

6.5m*1.5m*1.4m |

|

|

4KWwithCycloidalreducer |

|

|

4KW |

|

|

CB-E310 |

|

|

Φ70-90mm |

|

|

1000-1250mm |

|

|

380V3phase50HZorasthecustomer'srequirements |

|

|

Highgrade45#forgedsteelplatedwithhardchromeplating |

|

|

PLC |

|

|

8-12m/min(glazed tile is 2-3m/min) |

|

|

Cr12mouldsteelwithquenchedtreatment |

|

|

11-20Rollers |

|

|

highgrade45#steel; Cr12quenching |

|

Rollers

In order to get high quality product, our machine adopts welded steel frame structure, AC frequency conversion motor reducer drive, chain transmission, roller surfaces polishing, hard plating, heat treatment and chrome coating.

Roller Station:11-18rows

Or custome an customer's requirements Thickness of feeding material:0.3-0.8mm

Computer Control Cabinet

It adopts MITSUBISHI PLC to control. The target piece`s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use.

Hydraulic Station

It is derived by a Gear Pump. After filling the hydraulic oil into the hydraulic oil tank, the pump could drive the hydraulic cylinder to realize the cutting function.The system includes a set of hydraulic tank, a set of a Gear Pump, two hydraulic pipes .and two sets of Solenoid Valves.

Power of The Pump:4kw

Hydraulic oil :40#

more information you can view here

Send product request

Other supplier products

| Plate punching marking machine | Plate punching marking machine Punching marking making machine iron aluminum plate punching making machine Specification: Dimension:200cmx190cm... | |

| Supermarket shelf panel making machine | Supermarket shelf panel making machine customize steel plate making machine More details: Size: 8.0M*1.0M*1.0M Mateiral: Iron Product Featur... | |

| sandwich panel roll forming machine | sandwich panel roll forming machine EPS sandwich panel roll forming machine,roll forming machine,composite board making machine Product Applicati... | |

| roof wall panel double layer roll forming machine | roof wall panel double layer roll forming machine roll forming machine double layer roll forming machine Product Application: This type of roof... | |

| lightweight building board molding | Light Steel Keel Making Machine,Furring Roll Forming Machine Light Steel Keel Making Machine Supplier, lightweight building board moldingmachine Pr... |

Same products

| AEMK 588 Loader | Seller: AEMK MACHINE CO.,LTD | Cab Height :2670mm Overall Dimensions ( L * W * H ):5700*2000*2670mm Front Wheel Counterweight ... | |

| Quick Change Worktable | Seller: Nextas Co.,Ltd | Quick Change Worktable Zero Point Pneumatic Chuck Zero Point Positioning Datum System NE... | |

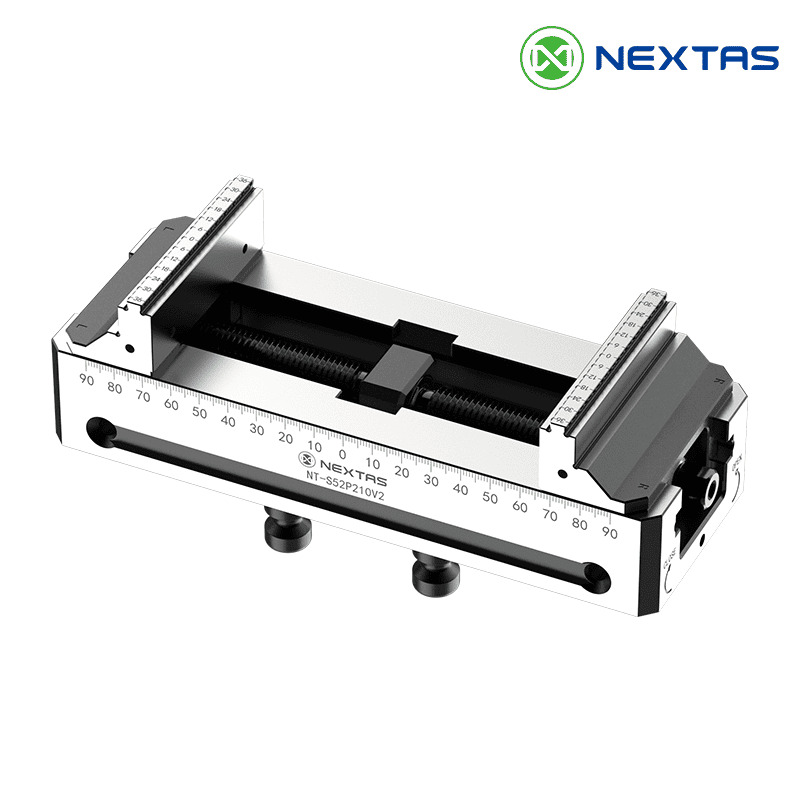

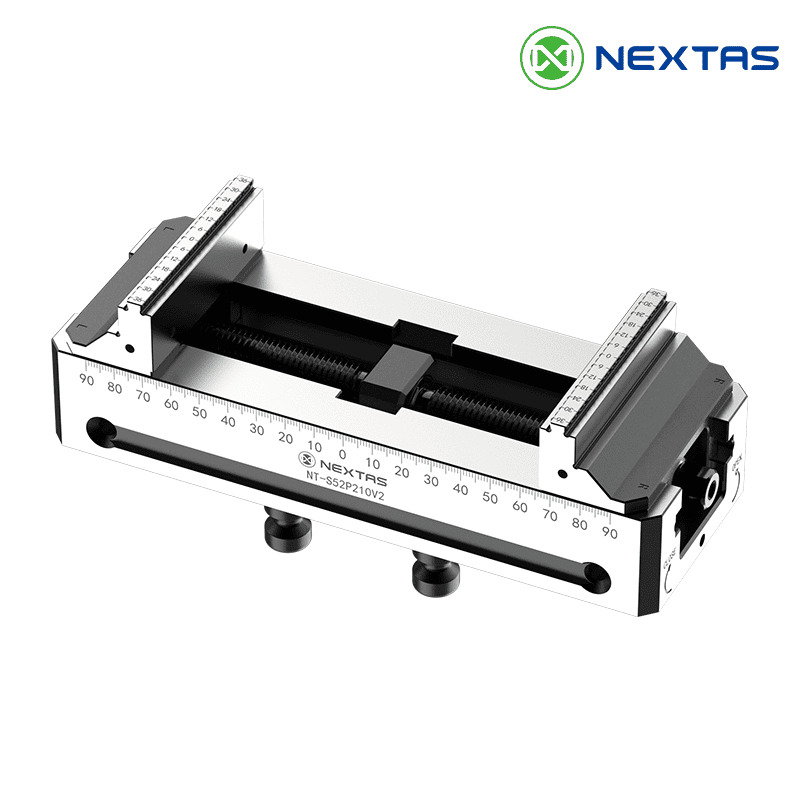

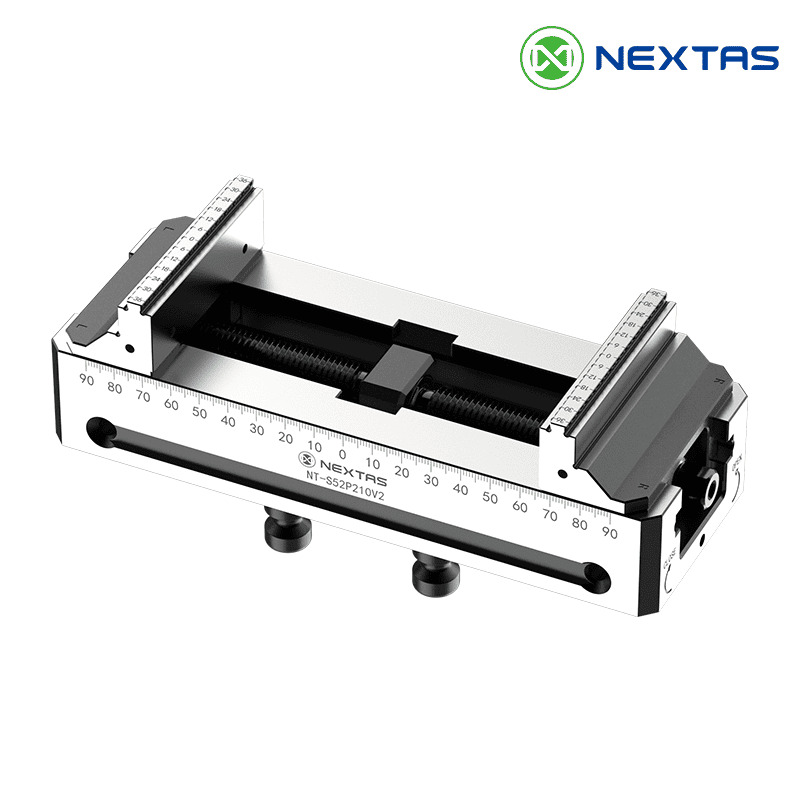

| Self Centering Vise | Seller: Nextas Co.,Ltd | Self Centering Vise Key Advantages High precision: repeatability as tight as ≤ 0.005 mm ... | |

| BDS Positioning Chuck | Seller: Nextas Co.,Ltd | BDS Positioning Chuck Self Centering Vise Self-centering vise is a type of workholding tool that... | |

| Quick Change Pallet System | Seller: Nextas Co.,Ltd | Quick Change Pallet System Quick Change Pallet System Quick Change Pallet System delivers m... |