PLC Control Technology of FTM Wood Pellet Mill

Wood pellet mill, also named as wood pellet machine, is mainly used to produce the particle fodders. The performance of wood pellet making machine can directly influence the manufacturing quality of particle fodders. Technologies for automatically controlling the feeding speed of wood pellet mill can ensure the stability of working current, exert the greatest value for production and avoid the material blocking. For the dynamo of feeder, it is equipped with the frequency converter for frequency control.

As to the electric control center, it uses the PLC control technology. Before the working process of wood pellet machine, you should input the required current for the normal working in the PLC controlling parameter. In general, the required current should be about 80%~95%of the rated current. During theworking process of wood pellet machine, PLC control center can make the analysis between the actual values and set value. If the actual value is less than the set value, you should accelerate the feeding speed and intensify the feeding amount.

On the contrary, you should lower the feeding frequency and decrease the feeding amount. Through the feasible and reasonable programming control, PLC control technology can greatly ensure the stability of working current, fully exert the granulating performance and reduce the failure rate of wood pellet press. Known as the NO.1 brand of China Mining Machinery,FTM China Machinerylooks forward to working with you in the near future. Please leave messages on the following website to get the discount for only three days.

Fote Heavy Machinery:

Fote Official Email:

Send product request

Other supplier products

All supplier products

Mobile Crusher: Strong Support for House Quality

In recent years, it is not strange to see some news on TV about the tragedy that people’s lives are threatened and suffered by the collapsed ...

Importance of Roller Skin for Coal Briquette Press

For the service life of coal briquette press machine, a key factor is the texture of roller skin. If there is something wrong with the roller skin,...

Molding Technologies of FTM Sawdust Pellet Mill

With saw dust, straw and hull as raw materials, sawdust pellet mill is able to process them into the biomass pellets. Featured in the high output, ...

Key Devices Equipped for Coal Briquetting Plant

With the amazing ability to turn coal wastes into briquettes of great value, coal briquette machine is an important part for the briquette plant. A...

Process to Record Parameter of Sawdust Pellet Mill

By taking the biomass pellets to make the durability test, you can check the carbon content inside. Besides, you should check whether the feeding p...

Same products

PV System

Seller: Sunrise Energy Co., Ltd

PV SYSTEMS

On Grid PV system

Self-generation, surplus power online, monthly income from elect...

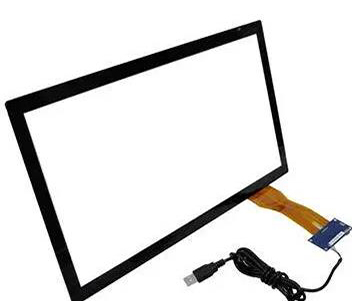

Special Shape LCD TFT Display Module

Seller: Shenzhen EXSON Technology CO.,LTD

Special shape LCD displays have become more and more popular in home appliances, Smart Metering e...

Panel Saw S350

Seller: Qingdao United Sonda International Trade Co., Ltd.

Model

S350

MainBladeDiameter

350*30mm

MainBladeSpeed

4...

Panel Saw S315

Seller: Qingdao United Sonda International Trade Co., Ltd.

Model

S350

MainBladeDiameter

350*30mm

MainBladeSpeed

4...

CORNER ROUNDING MACHINE MS-60

Seller: Qingdao United Sonda International Trade Co., Ltd.

Power Source:220/50HZzmm

Motor Speed(Max.):31000r/min

Processing Height(Max.):60mm

Comer Knife...