Desilter

Desilter

GN Desilter Discription

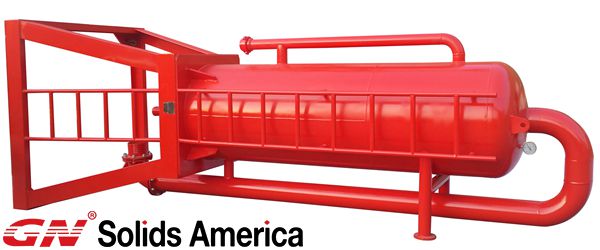

Desilter is the third stage solids control and fourth stage drilling mud cleaning equipment in the drilling fluids recycling system. GN Desilter commonly adapts 4” cyclone which could separate the solid phase particles with size of 15-25 microns. GN Desilter is designed 2 options of with and without underflow screen for customers’ requirement.

Thedesilterwith underflow shaker is also called Mini cleaner which is applicable for both weighted and unweighted drilling mud, while traditional desander no underflow vibrating screen only for unweighted drilling fluids. And comparing with large size desander and desilter assembly, the Mini Desander is cost-effective. For compact mud system used in HDD, CBM, water well drilling and Mining project, Mini desilter cleaner is an Ideal choice.

Desilter Options for different Application

Desilter Discription

Type:Desilter without downstream drying shale shaker Model:GNWSE-12N / GNWSE-16N Desilter Application: For oil gas drilling un-weighted drilling mud. Features:Small footprint, economic choice, no consumable screens. Result: Wet cuttings, not recommended for Weighted mud and drying solids.

Type:Desilter with GNZS752 Series Mini Shale Shaker Screen Area:1.35㎡ Model:GNZJ752E-8N / GNZJ752E-12N Desilter Application:For oil gas drilling small drilling rig , CBM drilling, HDD, Water Well drilling. Features:Small footprint, economic choice, acceptable drying solids.

Type:Desilter with GNZS703 Series 3 Panel Shale Shaker Screen Area:2.6㎡ Model:GNZJ703E-D8N/ GNZJ703E-D12N/ GNZJ703E-16N Desilter Application:For oil gas drilling big drilling rig , large HDD rig, Tunneling Boring Machine etc. Features:Big capacity,, drying solids.

GN Desilter Features:

- Desilter Options with shaker and without shaker for flexible applicaiton.

- Desilter cones with PU material with better Abrasion resistance

- No under shaker design structure compact and assembly flexible

- Mini desilter cleaner with shaker for both weighted / unweighted mud in various drilling

Mud Desilter for Drilling Mud Separation System:

Desilter is placed after desander but before Decanter Centrifuge. Desilter is also one type equipment to remove the solid particle in drilling through centrifugal force. Desander could remove the much fine solids than desander. During HDD and CBM mud system, the drilling mud after treated by desilter is clean enough for reuse. While in oil & gas drilling, there the mud still needs to be treated by a Decanter Centrifuge.

GN Solids America, your reliable supplier for drilling mud Desilter.

Send product request

Other supplier products

| Mud Gas Separator | Mud Gas Separator GNZYQ Mud Gas Separator Features and Benefits Baffle plates within vessel creates Maximum removal of free gas Skid-mounted desig... | |

| Shale Shaker | Shale Shaker GNZS Linear Motion Shale Shaker Features & Benefits: Ajustable High G force for primarysolids controlor cuttings drying. Heat tr... | |

| Centrifugal Pump | Centrifugal Pump Long-life mechanical seal Thick, strong, concentric casing Famous brand bearing Open impeller design, lower axial thrust loads, e... | |

| Mud Agitator | Mud Agitator GNJBQ Mud Agitator Discription: GN Mud agitator JBQ series mud Agitator, Less than 5.5 kW drilling mud Agitator adopts the blender c... | |

| Mud Cleaner | GNZJ Mud Cleaner Description GNZJMud Cleaneris the second stage and the third stagesolids control equipmentwhich is a combination of Desander, Desi... |