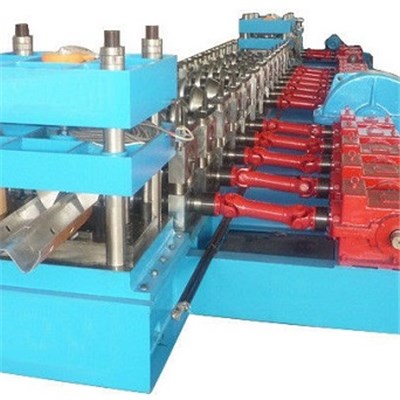

Ladder Type Cable Tray Roll Forming Machine

Working flow:Decoiler-----feeding and guiding----- leveling ------roll forming -----punching------ cutting----output

Machine components:

1

Manual Decoiler

1 set

2

Leveler

1 set

3

Punching press

1 set

4

Main Forming Machine

1 set

5

Hydraulic Station

1 set

6

Hydraulic Cutting Device

1 set

7

PLC Control System

1 set

8

Run Out Table

1 set

Technical description

Items

Parameter

Adapted raw material

Type

mild steel ,Galvanized strip coil and others

Hardness of sheet

≥350Map

Thickness of sheet

1~2.5 mm

Roll forming speed

10~15 m/min

Guding device

A pair of horizontal roller and two pairs of vertical guide rolls, total 1 sets

Leveling device

11 rolls, up 4/down 5, the residual 2 rolls is clamp deliver rolls

Roller material

45# steel polished and coated with chrome HRC55-60°

Roller stands

15

Shaft diameter

70mm

Shaft material

high grade No.45 steel after treatment

Air supply

Flow rate

0.5m3/min

Pressure

0.7MPa

Driving way

chain driving

Punching device

Each kind of width specification 1 set dies

Punching die

Cr12 quench

Cutting type

hydraulic cutting after forming

Blade material

Cr12 steel after treatment

Main power

About 15KW

Hydraulic power

11kw

Controlling system

PLC Frequency Control System with touch screen

Our Services Terms

Payment type

30% T/T prepaid and balance should be paid before loading

Delivery time

30 working days after receiving prepaid

Guarantee period

18months free service/ pay service all the machine life

Installation and training

If buyers visit our factory and check the machine, we will teach you how to install and use the machine, and also train your workers/technician face to face.Without visiting,we will send you user manual and video to teach you to install and operate.If buyer needs our technician to go to your local factory, please arrange board and lodging and other necessary things

Advantages1. We are factory and located in Shanghai,China,offer best quality machines

2. Customers Design ,Size,Color&Logo are accepted.3. With20 years professional manufacture experience4. Prompt Delivery&Competitive Price5. Main markets:Middle East, Europe, North America, Africa,Southeast Asia.

We can produce machine as different profile drawing.

FAQWHY CHOOSE AOFA COMPANY1) Q: Do you have after sales support? A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running. 2) Q: How do your machines compare with other big companies in this market? A: We are up to date with the latest technology and improve our machines accordingly 3) Q: Will you deliver the right goods as ordered? How can I trust you? A: Yes, we will. The core of our company culture is honesty and credit. AOFA is ALIBAB's Gold supplier with BV assessment and CE certificate. 4) Q: What can you do if the machine broken? A: Our machine's warranty period is 18months,if the broken parts can't repair,we can send the new parts replace the broken parts freell,but you need pay the express cost yourself.if after warranty period,we can through negotiationfor to solve the problems,and we supply the technical support for the whole life of the equipment. 5) Q: Can you be responsible for transport? A: Yes,please tell me the destination port or address.we have rich experience in transport. 6) Q: Can you supply the raw materials? A: Yes,we can supply the galvanized steel coil,galvalume steel coil,color steel coil,and aluminum coil.

Other supplier products

All supplier products

Same products