Oil Filter Performance Tester

The Oil Filter Performance Tester is a specialized laboratory system designed to evaluate the filtration efficiency, dirt-holding capacity, structural durability, and long-term performance of oil filters under repetitive contaminant-loading cycles. Using the multiple passes through test principle, the tester circulates contaminated oil through the filter element repeatedly, enabling fast and accurate simulation of real-world operating conditions.

1. Applications

The Oil Filter Performance Tester is widely used in industries requiring precise evaluation of filter performance under dynamic fluid contamination environments. Typical applications include:

Hydraulic System Filter Evaluation

Determines particle removal efficiency and pressure drop characteristics under repeated circulation.

Engine and Lubrication Filter Testing

Assesses filter clogging behavior, dirt-holding capacity, and long-term stability.

Research and Development

Supports new filter material development and comparative performance studies.

Quality Assurance / Certification

Ensures filters meet international testing requirements before delivery.

Fatigue and Durability Simulation

Reproduces long-term cyclic use to evaluate degradation and service life prediction.

2. Conformity Standards

This tester complies with major international and domestic filtration testing standards, including:

ISO 16889 — Multi-pass method for evaluating hydraulic filter performance

ASTM D5170 — Hydraulic filter multi-pass test procedures

ASTM D2060 — Wear and durability test methods

ASTM F3445 — Filter testing for various industrial applications

ISO 3724 — Filter element flow fatigue test

ISO/DIS 19438-2004 — Full-flow lubricating oil filter test

ISO 4548-12:2000 — Automotive oil filter multi-pass evaluation

GB/T 18853-2015 — Filter performance multi-pass test method

GB/T 8243.12-2007 — Automotive filter multi-pass test requirements

These standards ensure repeatability, accuracy, and global compatibility for certification and comparison.

3. System Components

The Oil Filter Performance Tester is composed of several precision modules designed for stable, long-term operation:

● Circulation and Pressure Control Unit

High-precision gear pump with strong self-priming capability

Stable flow delivery across the full test range

Smooth low-noise operation

● Contaminated Fluid Loop

Continuous circulation of test oil mixed with standardized test dust (SOFTC-2A)

Controlled contaminant adding system with adjustable ash rate

● Test Oil Tanks

30 L primary tank

10 L auxiliary tank

Optimized for thermal stability and consistent contaminant dispersion

● Differential Pressure Measurement System

High-accuracy sensors for 0–500 kPa measurement

Real-time monitoring of filter clogging and pressure drop behavior

● High Pressure Drop Resistance Function

Supports 0–1 MPa pressure simulations for evaluating structural fatigue and collapse resistance

● Temperature Control (Optional Configuration)

Adjustable medium temperature from room temperature to 90°C

Ensures compliance with temperature-related test protocols

4. Technical Parameters

| Parameter | Specification |

|---|---|

| Flow Range (Qv) | 5 L/min – 30 L/min |

| Pressure Drop Range | 0–500 kPa and 0–1 MPa |

| Media Temperature | Room temp. – 90°C |

| Differential Pressure Range | 0–500 kPa |

| Test Dust | SOFTC-2A |

| Main Oil Tank Capacity | 30 L |

| Auxiliary Oil Tank Capacity | 10 L |

| Ash Adding Rate | 0.06 × Qv g/h (0.3–1.8 g/h) |

Send product request

Other supplier products

| Racing Seat Headrest Restraint and Front-Rear Impact Testing Machine | The Racing Seat Headrest Restraint and Front-Rear Impact Testing Machine is designed to evaluate the strength and impact performance of racing seat... | |

| Automotive seat frame durability tester manufacturer | 1. Product Overview The Automotive Seat Frame Durability Tester is a precision testing system designed to evaluate the impact strength and energy ... | |

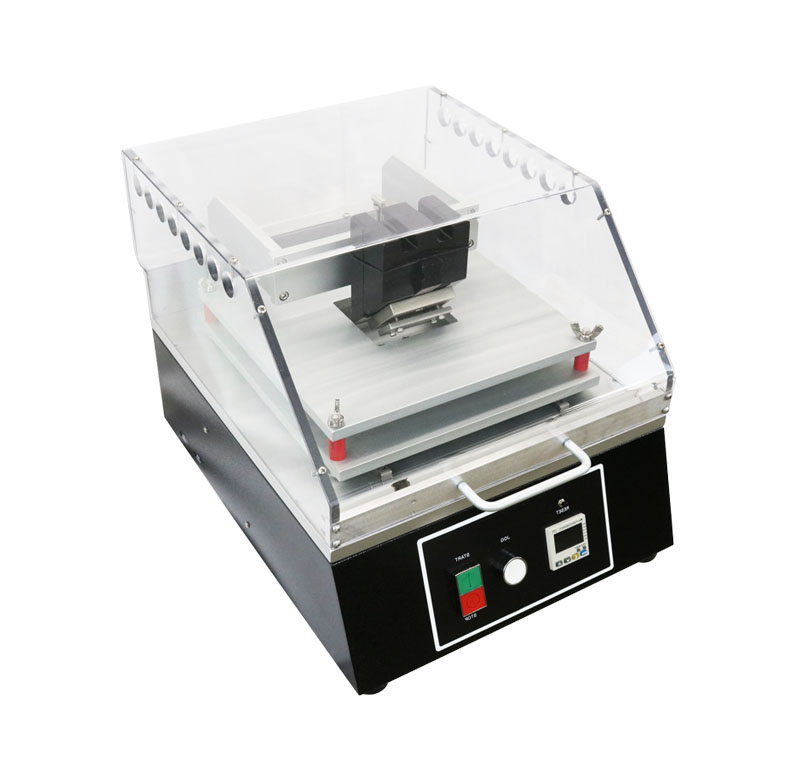

| Plastic ball indentation hardness tester | The Plastic Ball Indentation Hardness Tester is a precision instrument designed to evaluate the mechanical and hydraulic performance of plastic dra... | |

| Universal finger friction tester| Testing Equipment | Brief Introduction The main working principles of this device is through a test head, plus a certain amount of pressure, and carry a variety of st... | |

| Bubble Pressure Method Membrane Pore Size Analyzer | Instrument Standard Standard AbbreviationEnglish Translation GB/T 42269-2022 Pore Size of Separation Membranes - Gas Permeation Method... |

Same products

| Air Intake Filter Test System | Seller: Standard Groups | The Air Intake Filter Test System is designed for testing industrial air filters and engine air f... | |

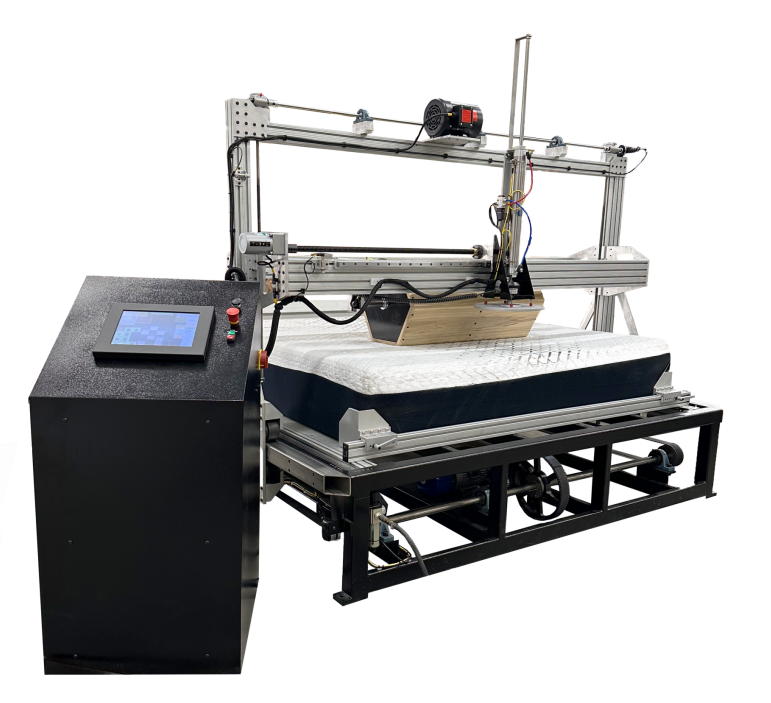

| Mattress Spring Fatigue Tester,ASTM D3574 ,how to test mattress for sagging | Seller: Standard International Group (HK) Limited | The King Size Foam Fatigue Tester is a single-station pneumatic fatigue testing system designed f... | |

| Mattress Rollator,ASTM F1566 ,Mattress Durability Tester,Mattress Fatigue Tester | Seller: Standard International Group (HK) Limited | The Mattress Rollator is a laboratory durability testing system designed to evaluate the long-ter... | |

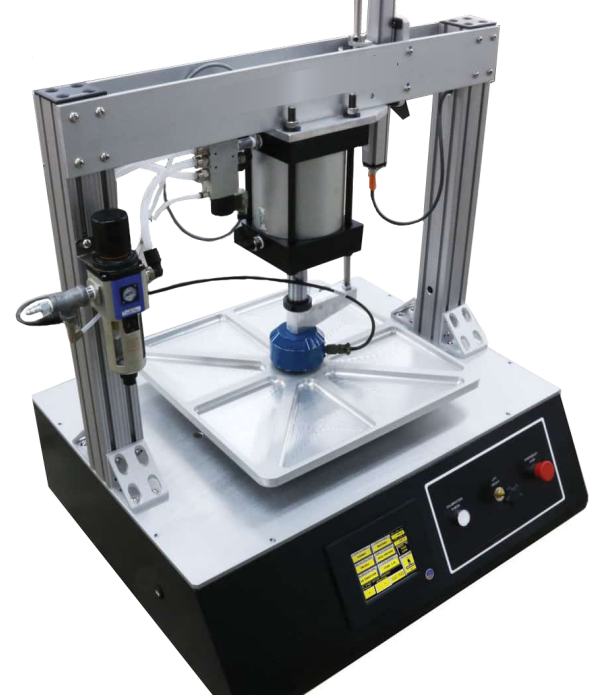

| HD2 Pneumatic Foam Fatigue Tester,ISO 3385,Foam Fatigue Testing Machine | Seller: Standard International Group (HK) Limited | The HD2 Pneumatic Foam Fatigue Tester is a heavy-duty, single-station laboratory testing machine ... | |

| VW Heel Abrasion Tester,ISO 4649 ,Heel Performance Testing Machine | Seller: Standard International Group (HK) Limited | The VW Heel Abrasion Tester is designed to evaluate the wear resistance of floor covering materia... |