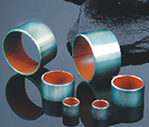

MARGINAL-LUBRICATION BEARING

1. POM 0.03-0.50mm, anti abrasion, low friction coefficient even no oil given. The inside of the bearing are full ofindentions, which need to be filled with grease before installing.

2.Bronze powder layer, 0.2-0.35mm, high load capacity and anti-abrasion, good thermal conductivity, which also further strengthen the combination of the POM layer and steel plate.

3. Low carbon steel, which improved, load capacity & thermal conductivity.

4. Copper/Tin plating layer, 0.002mm, anti-corrosion.

Other supplier products

|

|

Oilless Lubricating Bearing |

1. PTFE/Pb Composition, 0.01-0.003mm, anti-abrasion material, which will form a lubricating film during operation.

2. Bronze powder layer, 0.2-0.3... |

|

|

Self-lubricating plate |

Combined with the wear resistance of copper alloy and solid self-lubricating properties of the lubricant to use in the process of maintaining witho... |

|

|

Thrust Washers |

Combined with the wear resistance of copper alloy and solid self-lubricating properties of the lubricant to use in the process of maintaining witho... |

|

|

Morrison bronze bearings |

The bearings are wrapped of a cold formable homogenous bronze (CuSn8), which will obtain exceptional material properties. The standard size are fit... |

|

|

Self-lubricating track |

Combined with the wear resistance of copper alloy and solid self-lubricating properties of the lubricant to use in the process of maintaining witho... |

All supplier products

Same products