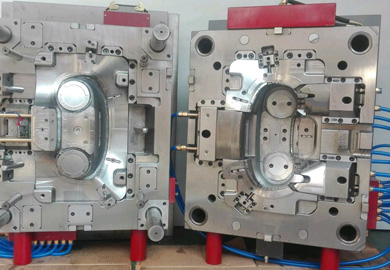

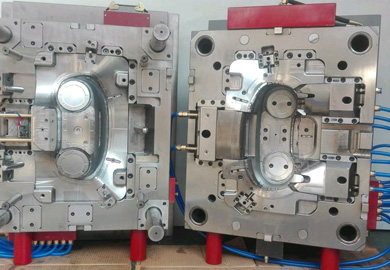

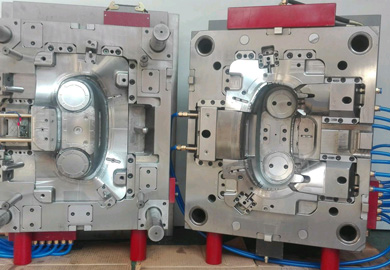

Die Casting Mould

Die casting mould is a method of casting liquid die forging. It is a process completed in a special die casting moulding machine.

The major advantage of mould die casting is that thousands of castings can be produced quickly by die casting mould supplier, die casting mould factory, die casting mould manufacturerthrough one mould. All mould components and parts of die castings are manufactured in mass mount at relatively low unit costs.

Features of Die Casting Mould

Die casting mound technology offers many outstanding features which include:

High corrosion resistance

High strength and hardness

High thermal conductivity

High electrical conductivity

Good processing properties

As one of the die manufacturer, GM-TECH provides you with CNC or ultrasonic removal of the part nozzle, rotary hole, tapping, and so on. Since there are many benefits of the die casting mould, please do not hesitate to contact us if you are interested in our products.

Specification of Die Casting Mould

|

Part material |

zinc alloy |

|

Cavity |

1 |

|

Mould steel |

H 13 |

|

Mould steel |

|

|

Mould life |

10W |

|

Mould standard |

HASCO |

|

Mould structure |

direct ejection |

|

Exporting country |

Russia |

|

Leadtime |

5 weeks |

|

Mould quality customer satisfaction |

99% |

|

FAI pass rate |

99% |

|

Project cooperation service customer satisfaction |

98% |

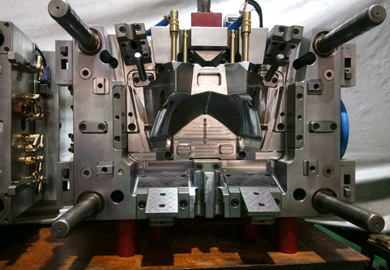

How does Die Casting Mould Work?

The basic working process of the die casting mould cnc components is as follows. The liquid metal first low speed or high-speed casting filling mold into the mold cavity. The die casting mould has an active cavity surface with the cooling process of the liquid metal pressure forging.

It not only eliminates the blank shrinkage cavity shrinkage porosity defects but also makes the blank internal organization reach the forged state of broken grains. The comprehensive mechanical properties of the blank are remarkably improved.

If you want to know more details of plastic mold technology, please visit our website.

Send product request

Other supplier products

| Medical Equipment Mould | Medical products include syringes, and internal and external parts of medical equipment. Features of medical device injection molding Our company ... | |

| 2k Injection Molding Factory | 2k Injection Molding Factory 2k injection mouldingis a manufacturing process that refers to molding two materials or colors into one plastic part.... | |

| CNC Components | Gmmoldtech CNC component can greatly reduces the number of tooling, and complex tooling is not needed to process complex parts. If we want to ch... | |

| Electronics Product Mould | Decades of accumulation of mould manufacturing technology have witnessed the popularity of electrical plastic molding products. The electronics ... | |

| Household&Home Appliance Mould | Household&Home Appliance Mould Home appliance moldcombines different types of molds such as gold stamping mould, plastic mould, and adsorption... |

Same products

| Motorcycle Body and Frame Plastic Mold | Seller: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould For 2021 Honda CRV | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | Seller: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |