Metal Bellow Mechanical Seals

Metal Bellow seals are ideal for high temperature applications and harsh chemical services where elastomers cannot be used effectively. This seal type incorporates metal bellows as a spring-loading mechanism to maintain face contact when the seal is not pressurized and eliminates traditional secondary sealing requirements.

In applications where the process temperature exceeds elastomer capabilities, metal bellows mechanical sealswith graphite secondary seals are a good sealing option. Metal Bellows Single Seal is designed for high-temperature services typically found in chemical and petrochemical processes. Graphite secondary seals replace O-Rings to achieve the higher temperature requirements.

Advanced bellows design distributes pressure uniformly across the span of the bellows plate to reduce stress and minimize weld fatigue. Component design replaces most OEM seals.

Features ofMetal Bellow Mechanical Seals

- For unstepped shafts

- Single seal

- Balanced

- Independent of direction of rotation

- Metal bellows rotating

- Asymmetric bellows form results in even stress distribution with benefits of greater strength and higher rate of flexibilty; seal is bi-rotational and inherently pressure balanced.

- Smooth profile is resistant to clogging and therefore ideal for slurries and fibrous liquids. Similarly, seal unit is easy to clean and sterilize in place.

- Unit construction ensures a simple-to-fit seal, with superior heat dissipation paths. Seal unit is reliable and does not wear the shaft.

- Graphite secondary seals for high-temperature performance

- Advanced bellows design for maximum cycle life

- Rotary bellows for enhanced performance in slurry and particulate services

- Hydraulically-balanced seal design

- Blister-resistant carbon

- Proven heat-treated AM 350 bellows construction

- Graphite secondary seals for high-temperature performance

Advantages ofMetal Bellow Mechanical Seals

- For extreme temperature ranges

- No dynamically loaded O-Ring

- Self-cleaning effect

- Short installation length possible

- Pumping screw for highly viscous media available (dependent on direction of rotation).

- For unstepped shafts

- Single seal

- Balanced

- Independent of direction of rotation

- Metal bellows rotating

- Rotating bellows

- Roller bellows

- Recommended applications

- Process industry

- Oil and gas industry

- Refining technology

- Petrochemical industry

- Chemical industry

- Hot media

- Cold media

- Highly viscous media

- Pumps

- Special rotating equipment

Materials Combination

- Face: Carbon, SiC, TC

- Seat: Ceramic, SiC, TC

- O-rings: NBR, EPDM, VITON, Aflas, FEP, Kalrez, Chemraz, Grofoil etc.

- Spring: SS316, hastelloy C, AM350

- Metal parts: SS316, hastelloy C

Common malfunction of metal bellow mechanical seals

- At high temperature, the bellows are easier to be broken, also the bellows are broken under high pressure (such as the hot water pump).

- It is easy to occur coking and carbon deposition at the trough between the wave plates, which makes the bellows lose elasticity and cannot compensate, so it can not be used for coking, carbon deposition and crystallized precipitation pump.

- For external installation mechanical seals, the sealing surface can be pushed open when the pressure in the sealing cavity is more than 0.2MPa. This is because the elastic force of the bellows is small and can not withstand the high pressure of the medium. Therefore, it is not possible to use an external bellows mechanical seal when the pressure is high.

- Because the metalis a balanced structure, the effective diameter and load factor must be calculated in use. Otherwise, in the high-pressure propane and propane pump, the phenomenon of "spray leakage" is easy to occur.

Send product request

Other supplier products

| METAL BELLOW MECHANICAL SEALS | Metal bellow mechanical seals are ideal for high temperature applications and harsh chemical services where elastomers cannot be used effectively. ... | |

| PTFE TEFLON BELLOW MECHANICAL SEALS | Polytetrafluoroethylene (PTFE) is one of the best corrosion resistant materials in the world. Therefore, it is called "the king of plastic". So the... | |

| Ceramic Seal | Ceramic material refers to inorganic non-metallic materials made of natural or synthetic compounds through forming and sintering. It has the advant... | |

| O.E.M MECHANICAL SEALS | With mechanical seal factory, Sealcon is able to design and manufacture a wide range of OEM mechanical seals. Our aim is to improve product quality... | |

| SINGLE CARTRIDGE SEALS | Our single cartridge type sealis manufactured by balanced seal-face technology, helping to reduce energy comsumption whilst increasing reliability.... |

Same products

| Quick-response Mechanical seal M74N-140 for power generation | Seller: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Quick-response Mechanical seal M74N-140 for power generation Is YOYIK for the use of turbine uni... | |

| Oil Seal 118*160*13 for Truck Auto Part Shaft NBR KDIK oil seal factory | Seller: Xingtai Honglei Seal Manufacturing Co., Ltd | Hot sale various high quality Truck oil seal from Chinaleading manufacturer. Our products are eff... | |

| Bh1941g Engine Timing Cover Seal Engine Camshaft Oil Seal | Seller: Xingtai Honglei Seal Manufacturing Co., Ltd | A Suzuki oil sealis a mechanical seal used to seal the gaps between the rotating shaft and the st... | |

| Transmission Oil Seal Bh4371e Tb 35*50*9.5 OEM for Toyota | Seller: Xingtai Honglei Seal Manufacturing Co., Ltd | Automotive oil sealsplay critical roles in different types of four wheeler vehicles. They are pri... | |

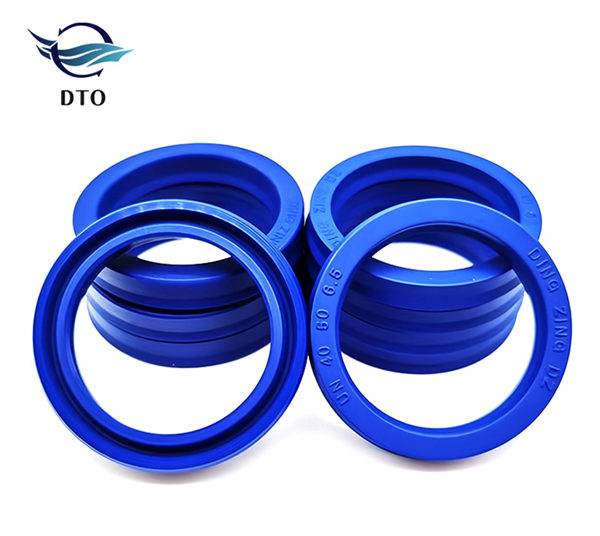

| UN Oil Seal | Seller: Xingtai Dingtong Rubber and Plastic Products Co., Ltd | A pliable, non-metallic PU ringis ingeniously nestled within a precision-machined groove or seaml... |