Back grinding wheels for thinning

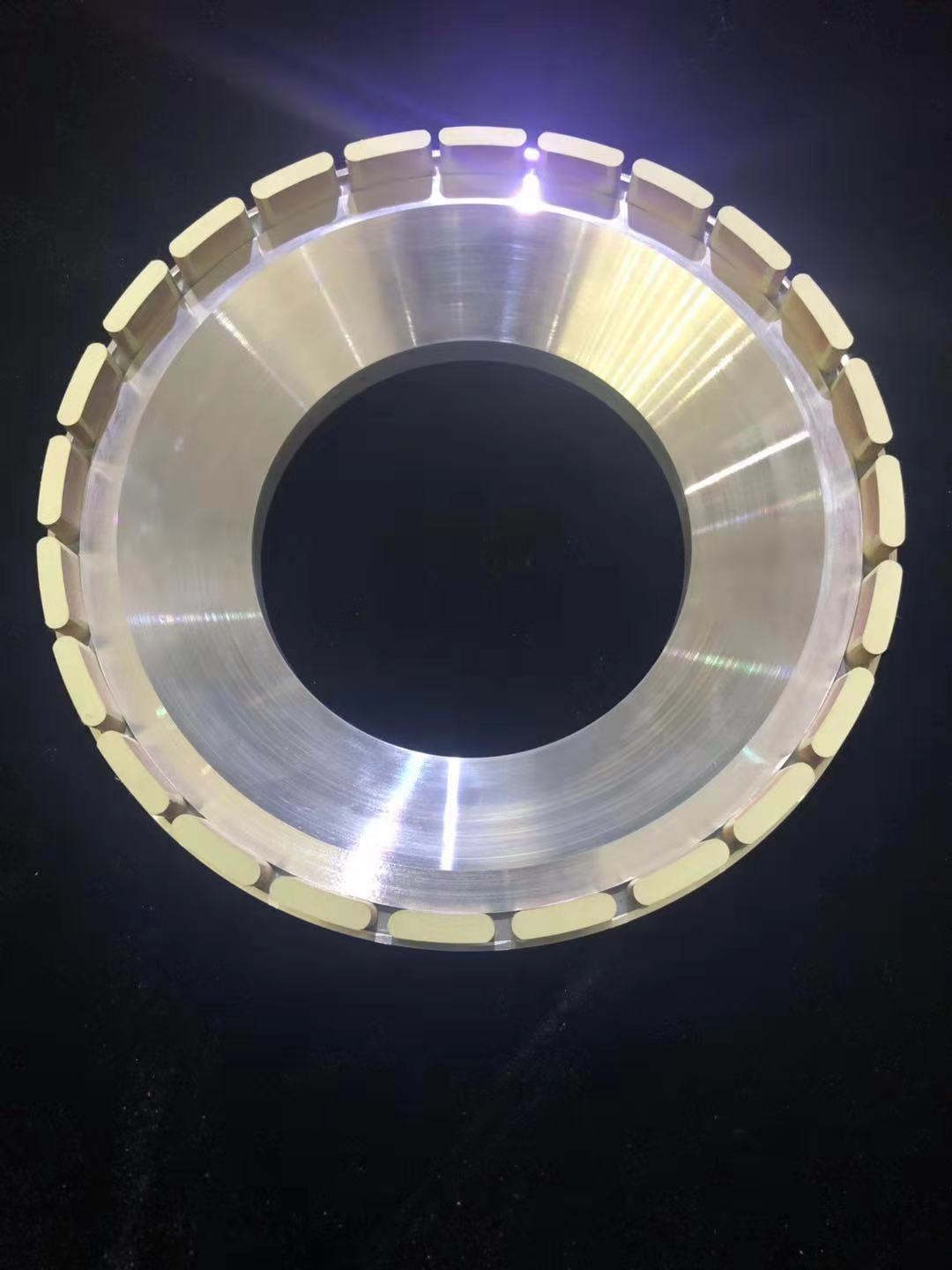

back grinding Wheel for inserts

Siliconwafer back grinding wheelsare mainly used for the thinning and fine grinding of the silicon wafer.

Coolant: Oil, emulsion

workpiece processed: silicon wafer of discrete devices, integrated chips (IC) and virgin,ATM, Melchiorre, Peter Wolters, Diskus, Viotto, Wendt

Material of workpiece: monocrystalline silicon and some other semiconductor materials.

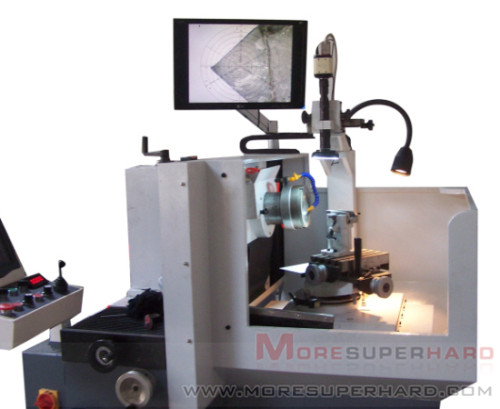

Grinders: SHUWA SGM-6301, NTS Nanosurface-180G, NTS Nanosurface 250/NC-VDM

Main role of back grinding wheel

In the middle of the pre-production process, thick silicon wafer can reduce damage; before assembly, silicon wafer is thinned, which is conducive to heat dissipation; reduce package volume; improve mechanical strength (softer after thinning, softer after thinning, minus Small stress); improve electrical performance (short connection); reduce the workload of dicing wafer

Vitrified bond suitable for silicon wafer back grinding wheel

Vitrified bond diamond grinding wheel bond agent has higher strength; good wear resistance, sharp cutting Grinding efficiency is high, and easy to trim; generally suitable for silicon wafers, such as rough grinding, semi-finishing grinding, etc.

The diamond grinding wheel has good self-sharpening performance and is not easy to clog; the grinding efficiency is high, the grinding force is small, and the grinding temperature is low The bonding agent itself has good elasticity and polishing performance; the workpiece has high surface finish and good surface quality; it is suitable for fine grinding and polishing of silicon wafers.

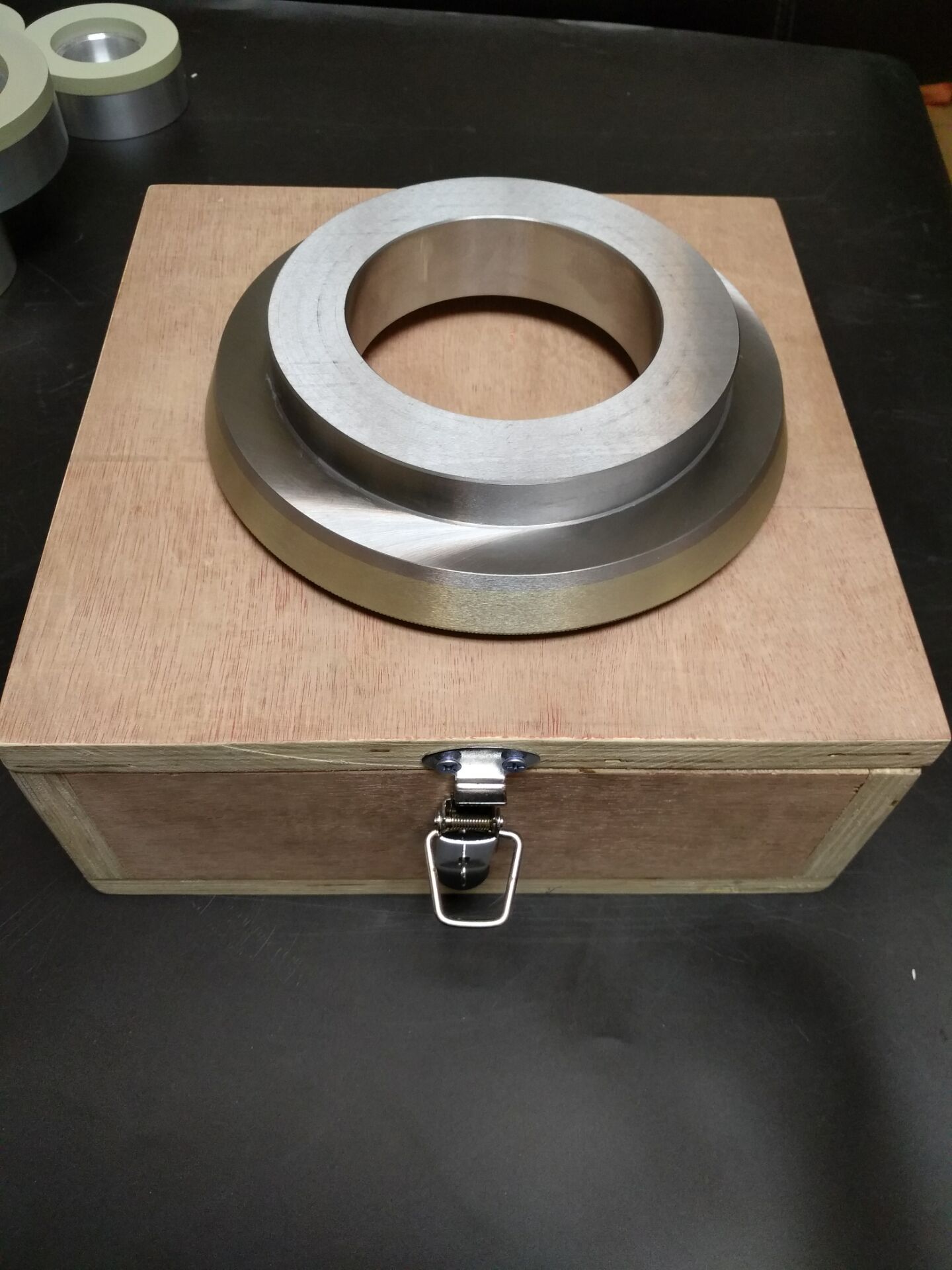

The Specification Of Diamond Back Grinding Wheels:

|

Model |

Diameter (Mm) |

Thickness (Mm) |

Hole (Mm) |

|

6A2 |

175 |

30, 35 |

76 |

|

200 |

35 |

76 |

|

|

350 |

45 |

127 |

|

|

6A2T |

195 |

170 |

|

|

280 |

30 |

||

|

6A2T(Three Ellipses) |

350 |

35 |

235 |

|

209 |

158 |

||

|

Other Size Can Ba Made According To Customers Requirements |

|||

silicon wafer back grinding wheel features:

1, surface quality: require grinding lines evenly, without chipping, debris, scribe, etc.;

2, processing accuracy: TTV <5 μm etc. (Total thinning veracity);

3, processing quality: surface roughness: < 10 nm; damage layer thickness: < 10 μm;

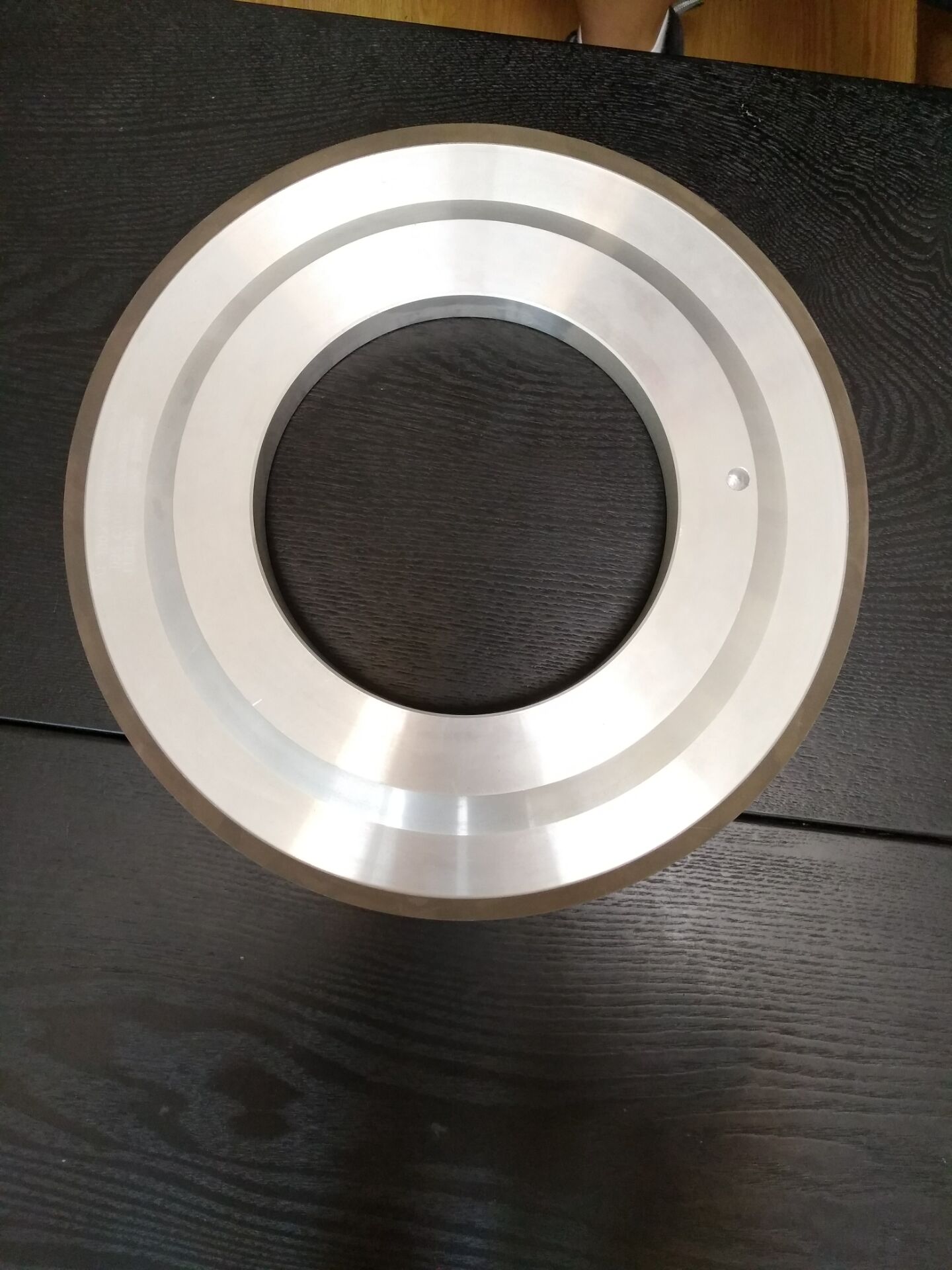

Applicationof back grinding wheel

The grinding wheels for LED substrateare mainly used for back thinning of sapphire epitaxial wafer, silicon wafer, gallium arsenide and GaN wafer.

Workpiece processed: sapphire epitaxial wafer, silicon wafer, gallium arsenide and GaN wafer.

Material of workpiece: synthetic sapphire, single crystal silicon, gallium arsenide and GaN materials.

The LED substrate thinning grinding wheel is mainly used for the back surface thinning of the sapphire epitaxial wafer, silicon wafer, gallium arsenide and gallium nitride wafer in the LED industry. The grinding LED substrate grinding wheel developed by our company has superior grinding performance and high cost performance. It can be used stably in European, American, Japanese and domestic grinding machines, and can replace imported products.

If you need any products, do not hesitate to contact

Send product request

Other supplier products

| Blade Type Diamond Dressers | diamond dresser for grinding wheel diamond dressersare used for dressing specific forms into conventional abrasive grinding wheels require longer ... | |

| 150G PCD & CBN Tool Grinder | 150G PCD & CBN Tool Grinder PCD & PCBN Tools Processing Industry Payment Terms: T/T, Western Union, MoneyGram, PayPal Email: | |

| DIAMOND ROLLER DRESSERS | Diamond dressing wheel is used for high-volume molding grinding plus Worker's high efficiency, high life, low cost wheel forming dressing tools. ... | |

| 3A1 diamond grinding wheels | 3A1 resin bond SDC diamond grinding wheels B 3A1 Strong slotting diamond grinding wheel Aplication: for processing of cylindrical and flat... | |

| Diamond Mounted Points & Diamond Burs | Diamond Mounted Points & Diamond Burs ElectroplatedDiamondTools Varied Grit Type: More Types Lead Time: 5 ~ 12 Days Payment Terms: ... |

Same products

| AF39M Purple Abrasive Film | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | AF39M Purple Abrasive Film RMC AF39M purple abrasive film discscan be used as Velcro and PSA dis... | |

| Abrasive Film | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | RMC micro abrasive filmis polyester film backing, with a perfectly flat surface and high strength... | |

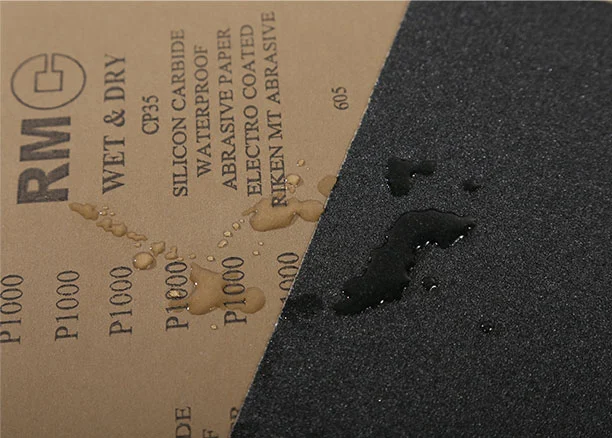

| C35P Silicon Carbide Sanding Paper | Seller: ZIBO SANKYO RIKAGAKU CO.,LTD | Wet & dry flexible latex, the inherent flexibility allows contour of irregular surface. Usual... | |

| AP82 Aluminum Oxide Sand Paper Roll | Seller: ZIBO SANKYO RIKAGAKU CO.,LTD | FUJISTAR Ewt velcro sanding rollAP82adopts the special backing paper with antistatic properties a... | |

| AP57 Sanding Paper Roll | Seller: ZIBO SANKYO RIKAGAKU CO.,LTD | FUJISTAR Ewt velcro backed sanding sheetsAP57 adopts the special antistatic backing paper and the... |