Ceramic Bond Diamond Grinding Wheel Surface Grinding Wheel Vitrified Grinding Wheel

Feature

Eliminate Thermal Damage

Due to the excellent cutting ability, thermal damage to metal workpiece is eliminated. When a CBN wheel is used for grinding, compressive stress remains on the workpiece surface. Both strength and wear resistance are improved, in comparison to grinding with a conventional wheel.

Easy Automation

Since the minimization of changed in wheel shape reduces the need for dressing, automation is easier than when using a conventional grinding wheel.

High-Accuracy Grinding Possible

High-accuracy grinding is possible because there are minimized wheel wear and high rigidity.

Tough Materials Are Machinable

Even difficult-to-cut ferrous materials that cannot be readily grounded by diamond or conventional wheels, can be grounded by CBN wheels.

Cost Reduction Per Piece

The high grinding ratio reduces the wheel cost per workpiece. Savings are also produced by less frequent dressing/truing. Rejects and regrinding are both reduced due to high-accuracy.

Vitrified Diamond Grinding Wheelsare mainly used for machining tungsten carbide, PCD, PCBN, ceramic, cermet, etc.

Vitrified CBN Grinding Wheelsare mainly used for machining cast iron(alloy cast iron, chilled cast iron, nodular cast iron, etc.) steel(45#,55#,20Cr.etc.)

Package:

Diamond grinding wheels body usually aluminum, to make sure it safe, we use pearl cotton and carton box pack it separately, then put into carton boxes.

Applications

Automotive parts grinding

Paper Manufacturing Industry

Bearing Industry

Aerospace industry

Turbine Industry

Grinding of PCD and PCBN

Profile grinding of TC threading plates

OD grinding of Printing Rolls, Shafts and Rods

Flat grinding of Ceramic components

Flat, OD and ID grinding operations of various parts

Grinding of Camshafts and Crankshafts

Finishing of turbine parts

Products advantages:

1. Better peformance

2. Longer Working Life

3. Shorter Part Cycle Times

4. Reduced Machine Fatigue

5. Application-Specific Finishing

6. Madefor Industrial Metals

7. Available in a variety of sizes

8. Safe and reliable

Send product request

Other supplier products

| Vitrified CBN Grinding Wheel for Camshaft | Description:Vitrified bond CBN Grinding Wheel is suitable for grinding the cam lobes of automobile camshafts.The wheel speed is 80m/s-160m/s,Design... | |

| 12A1 vitrified bond diamond and CBN grinding wheel | Introduction: Vitrified bond diamond grinding wheels possess pretty high abrasive resistance,especially in polishing hard and brittle work-piece. ... | |

| Electroplated Diamond / CBN Grinding Wheel | Electroplated grinding wheels with nickel bonding can achieve high stock removal rates and high-precision profiles on parts being ground. Depending... | |

| cup type diamond and CBN grinding wheel | Diamond grinding cup wheels are highly popular in the home improvement and construction industry. These are highly efficient in polishing, grinding... | |

| Vitrified diamond grinding wheels | Vitrified diamond grinding wheels are a kind of circular bonded abrasive with through-hole in the center which made of diamond powder and vitrified... |

Same products

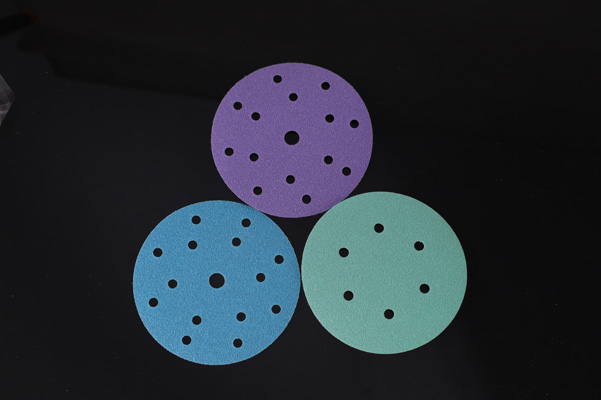

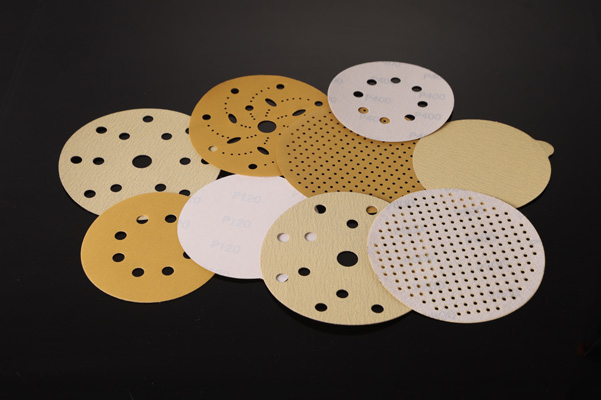

| AF38M Blue Abrasive Film | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | RMC AF38M blue abrasive film can be used as Velcro and PSA disc, and also suitable for different ... | |

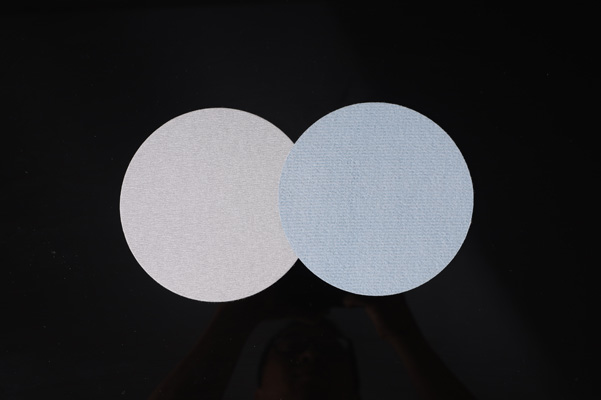

| AP36M Velcro Disc | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | RMC AP36M abrasive velcro sandpaper discsimpregnated latex, flexible. Special super stearated coa... | |

| AP36M PSA Sanding Discs | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | RMC AP36M abrasive paper PSA sanding discimpregnated latex, flexible. Special super stearated coa... | |

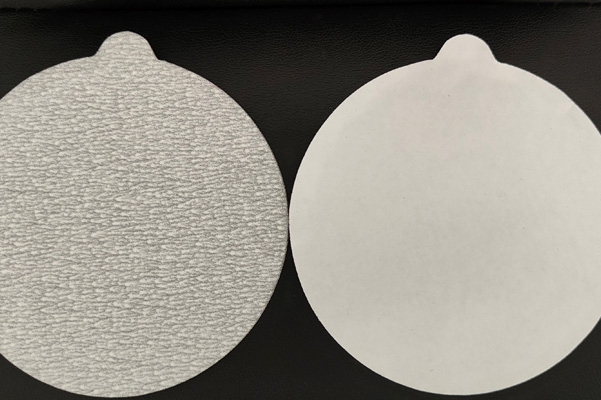

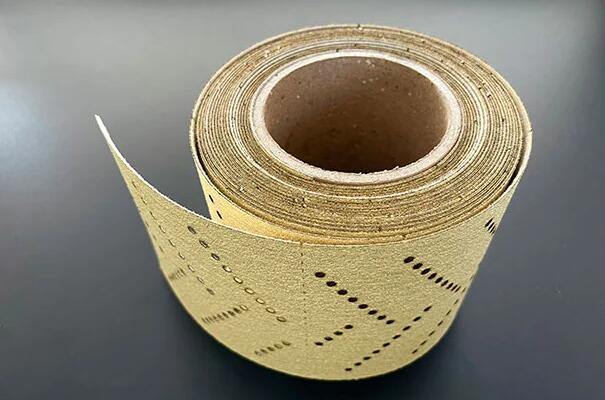

| AP33M Velcro Backed Sandpaper | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | RMC AP33M velcro sanding paperroll is a special sandpaper product suitable for fast sanding. Prem... | |

| AP33M PSA Sanding Discs | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | RMC AP33M PSA sanding discis a special sand paper product suitable for fast sanding. Premium alum... |