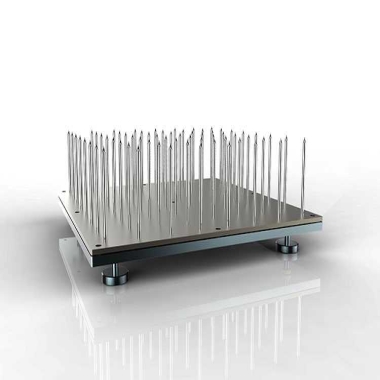

Abrasive Wear Testing Machine

Abrasive wear testing machines are mainly used to evaluate the surface wear performance of materials. They conduct abrasive wear tests on materials by simulating the friction and wear process under real working conditions.

Application

The wet - type rubber wheel abrasive wear testing machine is primarily employed to assess the wear - resistance of metal materials when they are in frictional contact with solids like sand, ores, and sediment. Through these tests, the capabilities of various metal materials to resist abrasive wear can be ascertained, and investigations into the abrasive wear mechanism can be carried out. This empowers the design, production, and scientific research departments related to mining machinery, construction machinery, transportation machinery, agricultural machinery, and so on to choose appropriate metal materials and manufacturing processes.

Standard

ASTM G65 - 04:Standard Test Method for Measuring Abrasion Using the Dry Sand/Rubber Wheel Apparatus

GB/T 3960-1983:Test method for friction and wear of plastics by sliding

Features

This testing machine is composed of two components: the main unit and the control system. The main - unit part comprises the machine base, main shaft and drive system, dead - weight loading system, and specimen clamping device. The control system includes the measurement and control section as well as the display instrument section. The two sections are linked by a control cable

Parameters

| Description | Details |

|---|---|

| Load | 100 Newton |

| Disc speed | 60. 120 rpm |

| Sample feed | 1. 2. 3. 4 mm / turn |

| Sample diameter | 2. 3. 4 mm |

| Auto-control system counting range | 0-99999999 (can be stopped at a given number of revolutions) |

| Overall dimensions | 560 × 540 × 1020mm |

| Weight | 350Kg |

Accessoriess

Test rings and blocks, abrasive paper, standard steel balls, test discs, etc.

Test Procedures

Equipment Inspection: Before use, check that the equipment is functioning properly, including the power supply, transmission system, control panel, sensors, and other components.

Sample Preparation: The shape, size, and surface treatment of the sample should meet the standard requirements. The sample must be cleaned before testing to remove surface contaminants and ensure the validity of the experimental results.

Test Parameter Setting: Set test parameters such as load, speed, temperature, and test time to simulate actual working conditions and obtain more representative test data.

Real-time Monitoring: During the test, monitor parameters such as the coefficient of friction and wear in real time and record the data for subsequent analysis.

Equipment Maintenance: After the test, clean and maintain the equipment promptly to ensure its long-term stability and reliability.

Send product request

Other supplier products

| Ink printing proof press meter | How it works: Ink printing proof machine is mainly based on the principle of printing reproduction, through the simulation of the press pressure, ... | |

| Rubber Low Temperature Brittleness Tester | The Rubber Low Temperature Brittleness Tester determines the temperature at which rubber and plastic samples become brittle under impact conditions... | |

| Furniture flammability tester | Furniture flammability tester is mainly used to test the combustion performance of mattress andupholstered bed. It’s suitable for bedspreads,... | |

| Whole shoe breathability and heat preservation testing machine | Standard SATRA TM376: Thermal insulation testing of footwear with sock integration. SATRA TM386: Water vapor permeability assessment for athlet... | |

| ASTM F963 Nail Bed Flammable Tester | G963 Nail Bed Flammable Tester, It is suitable for the burning performance test of cloth toys and filling materials. Perform the flammability of th... |

Same products

| Air Permeability Tester STD- F8 | Seller: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... | |

| Surface Performance Tester STD-FB4 - A | Seller: Standard International Group (HK) Limited | Introduction TheSurface Tester analyzes finger movements-particularly, strokes-performed by arti... | |

| Compression Tester STD - FB3 - A | Seller: Standard International Group (HK) Limited | TheCompression Tester analyzes hand movements-particularly, pushing with a finger-performed by ar... | |

| Single - Strand Bending Tester STD - FB2 - SH | Seller: Standard International Group (HK) Limited | Standards ASTM A370. ASTM A416. ISO6934.4 The Single Fiber Bending Tester makes it possible to ... | |

| Bending Tester STD- FB2 - S | Seller: Standard International Group (HK) Limited | Compliance Standards ASTM D790 (Plastics Flexural Properties) ISO 178 (Flexural Strength of Rig... |