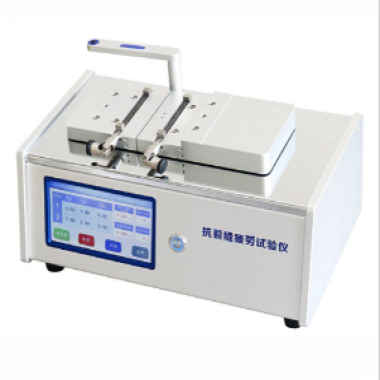

Medical injection needle rigidity tester

The Medical Injection Needle Rigidity Tester is designed to evaluate the mechanical rigidity of medical injection needles. It measures deflection and load under controlled conditions, ensuring that needles meet required standards for patient safety, comfort, and performance. The instrument supports a wide range of needle specifications and wall types, providing precise, repeatable results for manufacturers, laboratories, and regulatory testing.

Application

The tester is suitable for rigidity testing of medical injection needles in the following industries and products:

(1) Medical Device Manufacturing: Quality control of single-use, sterile injection needles.

(2) Research & Development: Testing new needle designs, wall thicknesses, and mechanical properties.

(3) Regulatory & Certification Labs: Compliance testing according to national and international standards.

(4) Third-Party Testing Organizations: Verification of needle rigidity for certification and reporting.

(5) Educational & Training Institutions: Demonstration and training on needle testing protocols.

Standards

The instrument is compliant with the following standards, including relevant international regulations:

(1) GB 18457-2001 – Medical Injection Needle Rigidity Performance Testing Standard

(2) ISO 7864:2016 – Sterile Hypodermic Needles for Single Use – Requirements and Test Methods

(3) ASTM F899-16 – Standard Test Method for Determining Needle Rigidity and Flexibility

(4) EN ISO 9626:2016 – Stainless Steel Needles for Medical Use – Mechanical Requirements

Features

(1) Precision compliance: engineered to meet global medical standards

(2) High accuracy: deflection measurement ±0.01 mm, load control ±0.1 N

(3) Versatile: supports needle diameters 0.3–3.4 mm and wall types (normal, thin, ultra-thin)

(4) User-friendly: automated testing, simplified setup

(5) Durable construction: compact, robust design (25 kg) with lifetime standard upgrades

(6) Adjustable span distance: 0–55 mm with ±0.5 mm accuracy

(7) Controlled loading speed: 1 mm/min ±0.1 mm/min

(8) Ergonomic design: compact footprint (460 × 340 × 400 mm) for laboratory efficiency

Technical Parameters

| Parameter | Specification |

|---|---|

| Deflection Measurement | 0–5 mm, Accuracy ±0.01 mm |

| Load Capacity | 5.5–60 N, Accuracy ±0.1 N |

| Span Adjustment | 0–55 mm, Accuracy ±0.5 mm |

| Needle Compatibility | 0.3–3.4 mm (Normal/Thin/Ultra-Thin Wall) |

| Loading Speed | 1 mm/min ±0.1 mm/min |

| Dimensions (L×W×H) | 460 × 340 × 400 mm |

| Weight | 25 kg |

| Power Supply | AC 220 V / 50 Hz or Customized |

| Warranty | 1 Year + Lifetime Standard Upgrades |

Accessories

(1) Main testing unit

(2) Calibration weights

(3) Specialized needle jigs and clamps

(4) Onboard thermal printer for instant data documentation

(5) User manual and calibration certificate

Test Procedures

(1) Mount the needle sample on the specified jig

(2) Set the span distance (0–55 mm) and loading speed (1 mm/min ±0.1 mm/min) on the controller

(3) Start the automated test to apply vertical force at the center of the span

(4) Measure deflection and load in real time via the integrated sensor

(5) Record results automatically or print via onboard thermal printer

(6) Compare measurements against standard thresholds for rigidity qualification

(7) Repeat for additional needle samples as required

Maintenance Information

(1) Keep the instrument clean and free from dust or debris

(2) Inspect clamps, sensors, and load cells regularly for wear or damage

(3) Calibrate the force transducer periodically to maintain measurement accuracy

(4) Avoid exposure to liquids, extreme temperatures, or mechanical shocks

(5) Ensure proper grounding of the power supply to protect electronic components

(6) Maintain logs of calibration, testing, and maintenance for compliance purposes

Send product request

Other supplier products

| Temperature Oxygen Index Apparatus, ISO4589-3, Nes 715 | Introduction: Temperature Oxygen IndexApparatus belongstoantiflamingtest equipment for measuring the combustion performance of the vertical bars... | |

| Anti-crack fatigue tester | Standard HG/T 4343 ASTM E739 ASTM E647 GB/T 3075 Functional features High precision measurement: The accuracy of the test results can be ensu... | |

| Circular Sample Cutter Tester | The Circular Sample Cutter Tester is a manual precision instrument designed to cut standardized circular specimens from textiles, fabrics, papers, ... | |

| Qinsun SUNTEST丨Xenon Arc Weathering Instruments | Modern desktop models, ideal instruments for 3D samples, equipped with various easy-to-use accessories, allowing SUNTEST to meet your different nee... | |

| Compression Fatigue Testing Machine | Standard YY/T 0959-2014 (China): Specifies compression fatigue testing protocols for intervertebral fusion devices, including load ratios, frequen... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |