Rack Rolling Machine

The automatic shelf column forming machine is mainly composed of decoiler, power leveling machine, servo feeding mechanism + punch punching mechanism, roller forming machine, electronic control system, hydraulic system, mechanical tracking shear mechanism, and other components.

The production line of our rack roll forming machine can produce 120× 69,100 × 69,80 ×69 shelf column profiles with a thickness of 1.2-2.5mm. At the same time, we can also customize production lines according to customer requirements.

Rack Rolling Machine Composition

Feeding, leveling, feeder, punching, forming machine, fixed-length cut off, receiving table, electrical cabinet (PLC control) and other components

Rack Rolling Machine Features

The material of the rolling roller is 40Cr, and the hardness is HB280 after tempering and tempering.

The transmission structure of the rack rolling machine is gearbox transmission or chain transmission.

Rack rolling machine adopts PLC full intelligent control, high automation program, safe and efficient.

The formed frame of the rack rolling machine is welded with high-strength channel steel. High strength, long service life.

The material of the forming mold is GCr15, quenching, hardness: hrc56-62 ℃.

Advantages of Rack Rolling Machine

As a professional manufacturer and exporter of all kinds of standard and non-standard cold roll forming lines and tube mill/pipe mill lines, Hangzhou Roll Forming Technology Co., Ltd produces rack roll forming machine that have the following characteristics:

First, adopting the unique punching die structure design, the rack rolling machine can greatly reduce the friction between the pipe and the die and avoid the damage of the material surface, so as to save the cost of secondary treatment of the material surface.

Second, the storage rack roll forming machine adopts a unique machine design, so that the punching process more streamlined and simplified. It can reduce material handling and greatly improve work efficiency.

Third, with the unique circuit design, oil design, and safety system design, our rack roll forming machine is also energy-saving, environment-friendly, safe and convenient.

Fourth, the equipment mold automatic discharge and blanking, thereby effectively improving the efficiency of punching and extending the service life of the mold.

Fifth, with great consistency over the rack roll forming process, the performance of our product quality is stable and guaranteed.

Welcome both national and international customers to contact us for more information.

For more information about rack rolling process, please feel free to contact us!

If you need any kinds of roll forming tube mill, please contact us, as a professional tube mill manufacturer, RF is willing to offer you high quality products.

Send product request

Other supplier products

| Direct Square Tube Mill Line | Direct Square Tube Mill Line is mainly used to produce the square and rectangular tubes directly, from square to square or rectangular to rectangul... | |

| SHELF PANEL ROLL FORMING MACHINE | This series of shelf rack roll forming machineare mainly used to make metal shelf panels. We also call this profile the box profile. The size and m... | |

| Metal Deck Roll Forming Machine | The metal deck roll forming lineis a steel structure building material produced by cold roll forming, which is used for supporting floor concrete i... | |

| Ridge Cap Roll Forming Machine | The series of metal roof ridge cap machine are mainly used to make ridge capping. Ridge capping is a critical part of the structure of a roof. Ridg... | |

| Coil Cart | Introduction of coil transfer cart Thecoil transfer trolleyallows for quick coil change, but the most important feature is eliminating coil dama... |

Same products

| 9606 Angle Grinder Chamfering Stand | Seller: Zhejiang Shijing Tools Co., Ltd. All Rights Reserved. | 1. High compatibility; fits over 90% of models on the market. 2. Constructed primarily from alum... | |

| 3025 Manual Ceramic Cutting Machine | Seller: Zhejiang Shijing Tools Co., Ltd. All Rights Reserved. | The 3025 Manual Ceramic Cutting Machine is a versatile and reliable tool designed for precision c... | |

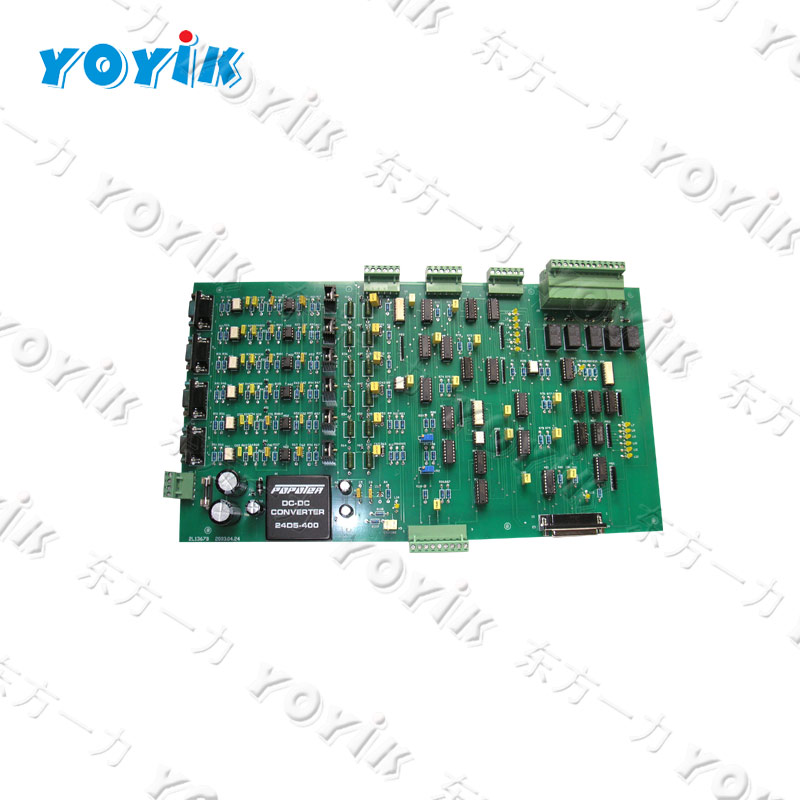

| China factory Open module ADAM-5056S for power station Sold by YOYIK | Seller: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | China factory Open module ADAM-5056S for power station Sold by YOYIK. Deyang YOYIK is a professio... | |

| Manual Tile Cutting | Seller: Zhejiang Shijing Tools Co., Ltd. All Rights Reserved. | Manual tile cuttingis a skill that has been honed over centuries, a craft that requires patience,... | |

| Downspout Roll Forming Machine | Seller: Zhejiang Jinggong Science & Technology Co., Ltd. | This downspout pipe roll forming machinecan produce the sealed color water pipes by forming the c... |