Cold Feed Extruder

Rubber extrusion vulcanization line is used in production of band, strip and tubular shape of dense and foam rubber products which used in building, electrical, mechanical, water conservancy etc industry. Production process: raw materials - mixer - rubber mixing machine - Extruder - vulcanizing box - cooling traction - packaging and storage. The features of this line: uniform vulcanization, quick vulcanizing speed, high efficiency, high product quality, low production costs, environmental protection and energy saving.

Second, the characteristics of the cold feed rubber extruder:

1. Cold feed rubber extruder adopts overall welding base, compact structure, safe and reliable, convenient installation and commissioning.

2. Gear reducer is rectangle hardened reducer with 6 precision gear; the cylindrical gear through carburizing and grinding tooth so of low noise, long life and endurance;

3. Screw is the core component of extruder which made of 38CrMoALA after nitriding treatment with wear-resistant, long life and high strength which can withstand high-torque and high-speed; Our company has made unique design to the screw thread structure according to the client’s rubber seal technology requirements, which divided into sub-fast feeding, slow progress, mixing and other five phases.

4. Barrel using cold, hot water circulation adjustment pumps or mold temperature device to adjust the temperature.

5. Motor with inverter control and adjustable speed.

6. Main Technical Parameters are as follows:

Technical Parameters XJP-75X20D XJP-90X20D XJP-120X20D XJP-150X20D

Screw Diameter(mm) 75 90 120 150

L : D 20:1 20:1 20:1 20:1

Screw Rotate Speed (r/min) 5-65 5-55 5-55 5-55

Max. Extruding Capacity (kg/h) 120 320 600 800

Main Motor Power(kw) 37 55 110 150

Speed Adjustment Mode variable frequency speed regulation

Weight (kg) 1700 3200 5200 6500

Other supplier products

|

|

Rubber kneader |

The machine is mainly uesd for plasticating and mixing of natural rubber,synthetic rubber,reclaimed rubber and plastics,foaming plastics,and used i... |

|

|

Rubber mixer |

Rubber mixer is mainly applicable for plasticing,warming and mixing rubber.

Machine with overturning equipment for rubber.

1. It mainly works fo... |

|

|

Rubber mixer |

Rubber mixer with overturning equipment for rubber is mainly used in plastering,warming and mixing rubber. |

|

|

Daylight Press |

Supply vairety of daylight press.Suitable for plasticity materials so the suppression techniques such as stamping, flanging thin stretch etc, also ... |

|

|

Plate Vulcanizing Press (Pillar Type) |

Character:

1. The machines used for rubber vulcanization are known as rubber vulcanizing machines.

2. This rubber vulcanizing machine strengthens r... |

All supplier products

Same products

|

|

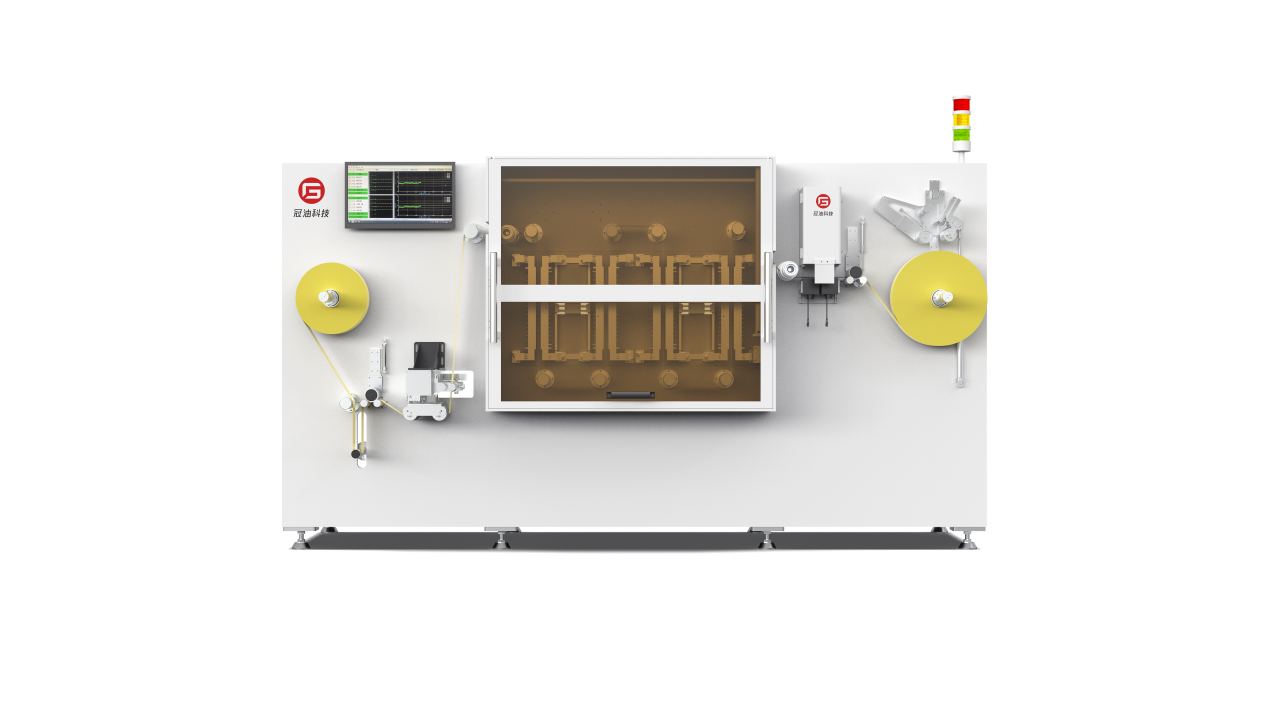

The Single Workstation Electrostatic Perforating Machine |

Seller: Wuhan Guan You Technology Co., Ltd. |

The single workstation electrostatic perforating machineis a professional cigarette paper static ... |

|

|

YZH WHEN1510 Stationary Pedestal Rockbreaker Boom |

Seller: Shandong Yirun Foundation Engineering Co., Ltd |

Below is a detailed introduction to the YZH WHEN1500 fixed hydraulic demolition arm, covering its... |

|

|

YZH WHEN1410 Stationary Pedestal Rockbreaker |

Seller: Shandong Yirun Foundation Engineering Co., Ltd |

YZH WHEN1410 Stationary Pedestal Rockbreaker is a specialized equipment designed for secondary cr... |

|

|

JY-160S2 Standard Plastic Injection Machine |

Seller: Dongguan Jieyang Machinery Co., Ltd |

Straight screw ejected assembly.

Two(three)-phase temperature, ejected speed, backing pressure a... |

|

|

WPC Terrace panel extrusion line |

Seller: Qingdao Trusty Plastic Machinery Co.,Ltd |

Wood-polymer composite (WPC), unlike wood, has higher resistance to aggressive environments and v... |