Ball mill

Ball Mill Introduction:

Ball Mill grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material to be ground. The rotation is usually between 4 to 20 revolutions per minute, depending upon the diameter of the mill. The larger the diameter, the slower the rotation. If the peripheral speed of the mill is too great, it begins to act like a centrifuge and the balls do not fall back, but stay on the perimeter of the mill. The point where the mill becomes a centrifuge is called the "Critical Speed", and ball mills usually operate at 65% to 75% of the critical speed.

Ball Mill Application:

are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reduced. Various classifiers, such as screens, spiral classifiers, cyclones and air classifiers are used for classifying the discharge from ball mills. Ball mill is an efficient tool for grinding many materials into fine powder. The ball mill is used to grind many kinds of mine and other materials, or to select the mine. It is widely used in building material, chemical industry, etc. There are two ways of grinding: the dry process and the wet process. It can be divided into tabular type and flowing type according to different forms of discharging material.

Ball Mill Features:

1) is an efficient tool for grinding many materials into fine powder.

2) The ball mill is used to grind many kinds of mine and other materials, or to select the mine

3) Ball mill is widely used in building material, and chemical industry.

4) There are two ways of grinding: the dry way and the wet way.

5) Ball mill can be divided into tabular type and flowing type according to differentexpelling mine

6) To use the ball mill, the material to be ground is loaded into the neoprene barrel that contains grinding media.

7) As the barrel rotates, the material is crushed between the individual pieces of grinding media that mix and crush the product into fine powder over a period of several hours.

8) The longer the ball mill runs, the finer the powder will be.

9) Ultimate particle size depends entirely on how hard the material you're grinding is, and the time how long the ball mill runs.

10) Our ball mills have been used to grind glass, powder food products, create custom varnishes, make ceramic glaze, powder various chemicals.

Ball mill Working Principle:

The ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

Other supplier products

|

|

Composite crusher |

The upright PFL series compound style crusher is that my factory brainpower needs according to the marketplace, the optimization being in progress ... |

|

|

Установка для получения песка Китай |

Sand making machine (namely PCL Vertical shaft impact crusher) is of high-power and low-consumption, which is designed depending on several years h... |

|

|

Magnetic separator |

Magnetic Separator detail information:

This magnetic separator can separate raw materials with different magnetic rigidities. The machine works by... |

|

|

Belt conveyor |

:

1.The belt conveyor produced by our company has the strongpoints of large conveying amount, simple structure, easy maintainance, high standardi... |

|

|

Impact crusher |

Impact Crusher is mainly used to crush many kinds of large, medium, small materials whose side length is less than 500mm, and compression resistanc... |

All supplier products

Same products

|

|

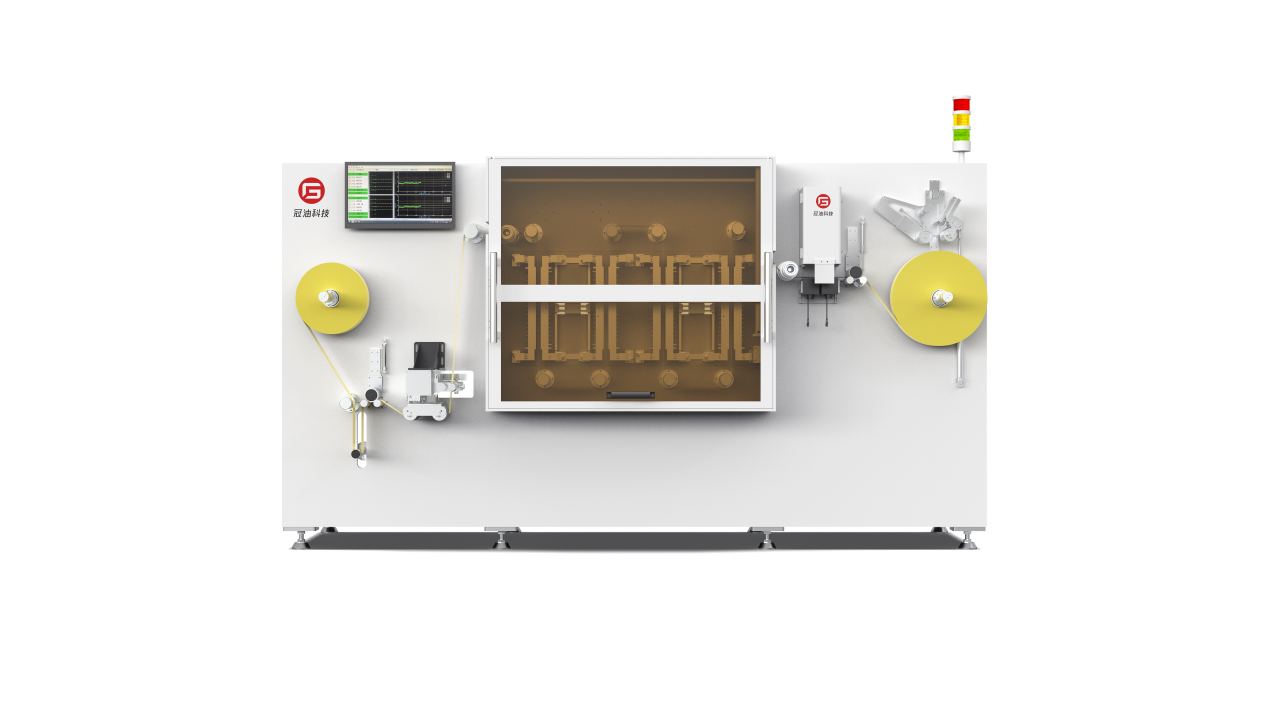

The Single Workstation Electrostatic Perforating Machine |

Seller: Wuhan Guan You Technology Co., Ltd. |

The single workstation electrostatic perforating machineis a professional cigarette paper static ... |

|

|

YZH WHEN1510 Stationary Pedestal Rockbreaker Boom |

Seller: Shandong Yirun Foundation Engineering Co., Ltd |

Below is a detailed introduction to the YZH WHEN1500 fixed hydraulic demolition arm, covering its... |

|

|

YZH WHEN1410 Stationary Pedestal Rockbreaker |

Seller: Shandong Yirun Foundation Engineering Co., Ltd |

YZH WHEN1410 Stationary Pedestal Rockbreaker is a specialized equipment designed for secondary cr... |

|

|

JY-160S2 Standard Plastic Injection Machine |

Seller: Dongguan Jieyang Machinery Co., Ltd |

Straight screw ejected assembly.

Two(three)-phase temperature, ejected speed, backing pressure a... |

|

|

WPC Terrace panel extrusion line |

Seller: Qingdao Trusty Plastic Machinery Co.,Ltd |

Wood-polymer composite (WPC), unlike wood, has higher resistance to aggressive environments and v... |