Expanded Mesh Slitting Line

All supplier products

Process flow:

The expanded mesh slitting line production line firstly use the de-coiler to initiative release galvanized steel plate or stainless steel sheet coil, coil cross the expanded main mesh machine feeding mechanism into the expanding link, expanded mesh machine cross the motor belt drive to send the power to the crankshaft, then drive the mold to do the up and down high speed shearing movement, expanded the sheet steel, then the next levelling and slitting machine expanded the required product size. Finally, automatic re-coiler start recoil the mesh.

The production line is applied to expanded mesh automatic continuous production, the main characteristic is high degree of automation, high accuracy, running safely and can reduce man cost, improve production efficient.

Structure description and draw:

The expanded mesh slitting line is composed of de-coiler, expanded metal machine, leveling and slitting machine, automatic re-coiler and electrical controlling cabinet.

De-coiler: use motor drive to re-coiler roller’s initiative release, easy to control, simple structure.

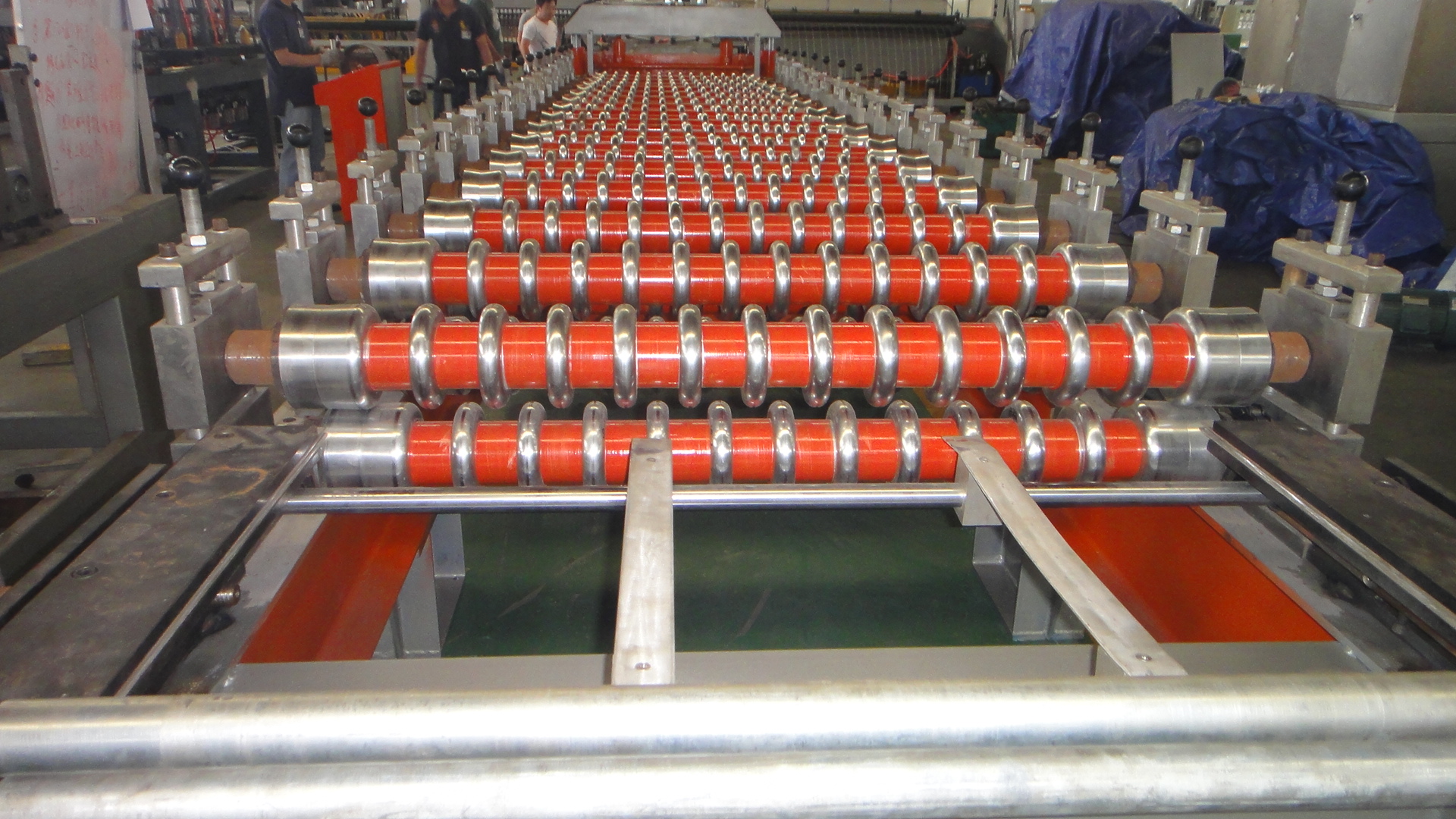

Expanding machine: Motor drive the belt pulley, send the power to crankshaft, then crankshaft drive the mold to do the up and down high speed running. At the same time, crankshaft’s rotary motion drive the feeding mechanism intermittent feeding, match the expanding action.

Leveling and slitting machine contains machine frame, roller leveling, slitting, etc. Motor sent the power to each roller to leveling expanded steel plate, then to the slitting part to shear, worker can adjust the mesh width.

Main technical parameters:

- De-coiler

- Φ40mm—Φ500mm, adjustable;

Loading weight: 2-3 tons;

Motor power: 2.2KW.

- Expanded metal mesh machine

Speed: 180-300 stroke per min;

Drive type: V belt drive;

Motor power: 4KW, 380V 50HZ;

Mould: Cr12MO1V1, hardness: HRC58-62

- Leveling and slitting machine

Motor: 2.2KW, 380V 50HZ;

Drive type: by chain

- Auto re-coiler

Motor: 1.5KW, 380V 50HZ;

Width of recoiling: 200-400mm, adjustable;

Quantity of re-coiler: 3 pieces.

- Electric control cabinet

PLC control; Electric element: Schneider.

Send product request

Other supplier products

| Steel coil cut to length line (0.7-6mm)×1600mm | The cut to length line is used to take flat rolled steel or coiled steel unroll it level it and cut it to desired length sheet. Moreover, any speci... | |

| ABE-4-2000 Expanded Metal Mesh Machine | Description of automatic expanded metal machine: ABE-4-2000 expanded metal machine is heavy-duty expanded metal machine. This kind of metal mesh i... | |

| Expanded Diamond hole metal mesh machine 1250mm | General description: ANBER high speed expanded mesh machine, it is high speed and CE certificated. Detailed description: Expend mesh machine is a ... | |

| Corrugated Roll Forming Machine | Specifications: Material: galvanized steel sheet Sheet thickness: 0.15-1.0mm Number of stations: 18 stationsn Rolling speed: about 12-20m/min Stru... | |

| slitting line machine | Introduction of the steel sheet slitting line: Slitting line machine is not only for the steel service cutting industry, but also for the pi... |

Same products

| Security screen mesh | Seller: Sharp Building Materials Sales Department | Diamond mesh is a high-strength, durable stainless steel screen that protects against mosquitoes ... | |

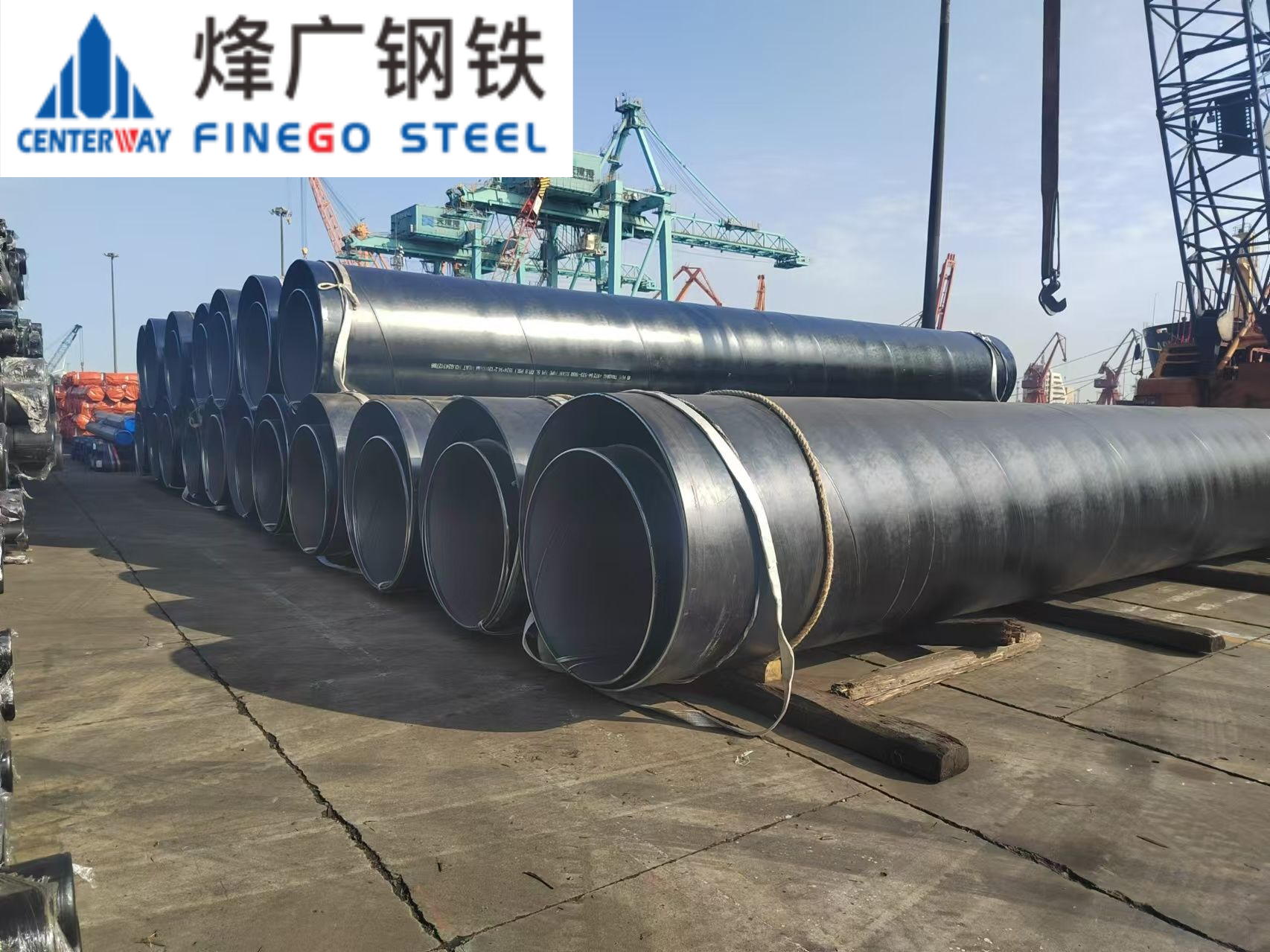

| Steel Pipe | Seller: Finego Steel | Find us: | |

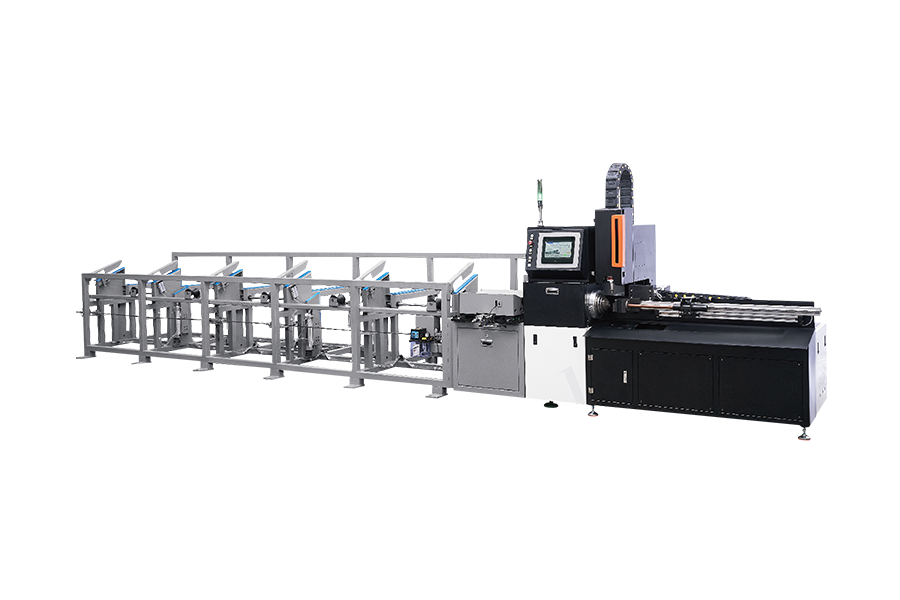

| JH-NC70-Cl3 (2023 Model) Automatic Three-Axis Cnc Laser Pipe Cutting Machine | Seller: Zhejiang Huaqi Information Technology Co., LTD | Introducing the JH-NC70-CL3 AUTOMATIC THREE-AXIS CNC LASER PIPE CUTTING MACHINE, a cutting-edge s... | |

| Railway Hydraulic Rail Gap Adjuster Railroad equipment supplier | Seller: 834406 | 液压导轨间隙调节机 YTF-400II液压导轨间隙调节器适用于43kg--75kg导轨。YTF-400II.液压导轨间隙调节机具有推拉小导轨接头两种功能,推导导轨、拉轨全部可,操作方便,效率高... | |

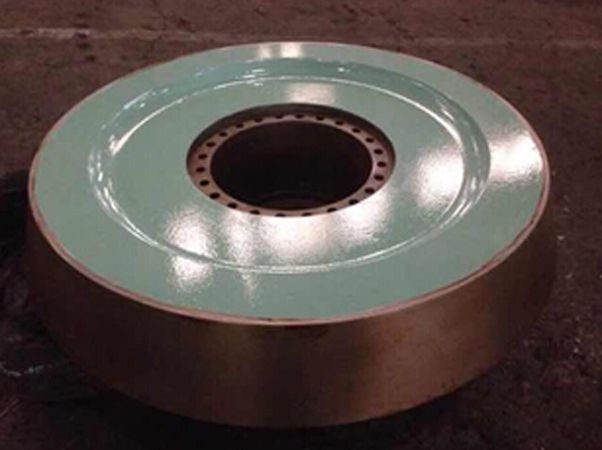

| Thrust Roller | Seller: CITIC IC LUOYANG HEAVY MACHINERY CO., LTD | CIC is a more than 30-year manufacturer and reputed supplier of thrust roller used in rotary kiln... |