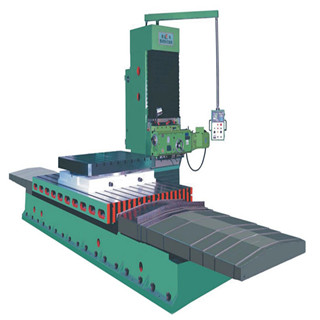

Various models Customized 3 axis Precision gantry milling machine

1. Machine tool main components: bed, table, beams, left and right columns, connecting beams, gantry are resin sand molding, high-quality high-alloy wear-resistant cast iron casting, hot bunker annealing → vibration aging → furnace annealing → Vibration aging → roughing → vibration aging → furnace annealing → vibration aging → finishing, completely eliminate the mechanical load, to maintain the stability of mechanical parts.

2. Bed, table guide using static pressure unloading and wear-resistant coating technology to ensure low speed stability and precision retention.

3. Machine three-way feed and milling head feed using separate drive mode, so that the various parts of the independent operation, improve work efficiency.

4. Spindle type boring and milling head spindle automatic transmission, feed ball screw drive, and the use of hydraulic balance cylinder device, balance the weight of the ram.

5. According to user requirements can provide a variety of forms of accessory milling head, to further expand the scope of use.

6. Electromechanical control system using PLC, digital AC servo control technology to achieve high precision and high reliability control.

7. Machine three-way feed using the international advanced level of AC variable frequency vector control, to achieve stepless speed regulation.

8. The table is set to touch screen settings, the table is operated as a suspension button station, accurate and convenient.

9. Machine table longitudinal X and boring milling head Y and ram vertical Z coordinate can be equipped with digital display device for easy operation and measurement.

Send product request

Other supplier products

| Heavy Duty High Precision Moving beam gantry machining center | Gantry machining center refers to the spindle axis and the table perpendicular to the processing center set, mainly for processing large parts. The... | |

| High stability cast iron Fixed beam Precision gantry milling machine manufacturer | Workbench and other activities of the mop, paste the import TURCITE.B, so that the friction coefficient reduced. Active forced lubrication system, ... | |

| Large CNC double - headed milling machine manufacturer | Double-headed milling machines are one of the most widely used milling machines in machinery manufacturing and assembly plants, and the difference ... | |

| Strong carrying capacity Large CNC Horizontal Milling Machine | 1. Spindle sleeve can be manually micro-feed, and set the limit device, milling head can be followed, counterclockwise rotation adjustment 45 °... | |

| Large high quality Precision CNC gantry machining center machine | Gantry machining center refers to the spindle axis and the table perpendicular to the processing center set, mainly for processing large parts. The... |

Same products

| The Ultimate Tool for Bubble-Free Displays | Seller: Shenzhen Wikshu Technology Co. | FORWARD FW-16R Bubble Remover and FW-8R Mini Bubble Removal Machine removes screen OCA bubbles du... | |

| Precision CNC Lathe With Conjoined Oblique Rail Cutter Tower | Seller: Zhejiang Guoyu CNC Machine Tool Co., Ltd. | Technical Characteristics: 45° slant bed base structure, with strict aging treatment, smooth ... | |

| Rail Welder A Frame aligners railway welding tools | Seller: 834406 | 产品描述 A型车架 A-Frame 是一种导轨对准器,可精确对准要焊接的导轨。该设备在焊接操作期间将导轨固定到位。 | |

| 2 parts fluid mixing dispenser 2 component dosing epoxy PU silicon rubber vacuum system | Seller: 824681 | What is the difference between 2K AB adhesive materials manual potting machine and robot pottingm... | |

| Horizontal Machining Center | Seller: Xilong (Shanghai) Machine Tool Co., Ltd. | Horizontal Machining Center parts can automatically finish four sides milling, boring, drilling, ... |