Microfiltration Ceramic Membrane Element

The ceramic microfiltration membraneelement ( MF membrane) is made from alumina and zirconia which is an asymmetric membrane structure with multi-channel tubular shape. The pore is on the channel. Driven by operation pressure, the liquid is running in the membrane. The part less than pore size is permeation, the part lager than pore size is concentrated liquid, so as to achieve the separation, concentration and purification purposes.

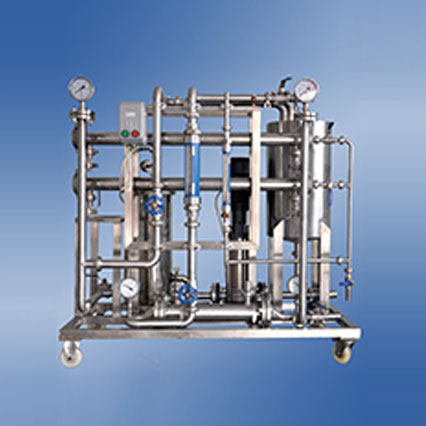

JIUWU ceramic membrane manufacturer produces the ceramic microfiltration membranes with the pore size 200nm, 500nm, 1200nm and so on. JIUWU microfiltration systemmade by high-quality MF membranes element will meet the requirements for your special applications.

OVER VIEW OF MICROFILTRATION CERAMIC MEMBRANE ELEMENT

Ceramic microfiltration membrane is a type of physical filter element where a contaminated fluid is passed through a special pore-sized membrane to separate microorganisms and suspended particles from process liquid. The most common application of ceramic microfiltration membrane is clarification, or removal of suspended solids to produce a clear liquid. It is commonly used in conjunction with various other separation processes such as ultrafiltration and reverse osmosis membrane technology to provide a product stream which is free of undesired contaminants. Examples include clarification of whole cell broths; purification processes in which macromolecules must be separated from other large molecules, enzymes or cell debris; clarification of dextrose and highly colored fruit juices, wine and beer, during which fruit juice membrane and beer membrane filtration will be used; whey de-fatting and casein removal. Ceramic microfiltration membrane systems operate at relatively low pressures and come in a variety of configurations. They are characterized by pore size, ranging from 0.05 micron to 1 micron.

JIUWU company offers a large choice of ceramic microfiltration membranes with different geometries and cut-offs to meet your process requirements in viscosity, molecule size, impurity profile, purity and yield target, etc. as well as cleaning and sanitization procedures.

MF ceramic membrane usually serves as a pre-treatment for other separation processes such as ultrafiltration, and a post-treatment for granular media filtration. Learn more micro filtration technologyhere!

APPLICATION OF MICROFILTRATION CERAMIC MEMBRANE ELEMENT

Remove suspended solid and reduce SS

Remove proteins, polysaccharides, pigments and other impurities

Remove bacterial

Dehydration

Concentration

Reduces COD / BOD

Membrane technology in food processing

Membrane filtration of milk

Ceramic membranes for wastewater treatment

JIANGSU JIUWU HI-TECH CO. LTD.,founded in 1997, focus on producing ceramic membrane filtersfor many years. And JIUWU HI-TECH has become a leading company in the membrane separation industry. We sincerely invite and welcome people from all around the world to invest and create more values together.

Send product request

Other supplier products

| Nanofiltration Ceramic Membrane Element | Ceramic membraneand other hi-tech membrane technology serve an important role in our daily life. JIUWUworks to provide our customers with the best ... | |

| Palm Oil Wastewater | Palm Oil Wastewater Palm oil is not only the highest yielding cheap vegetable oil on the earth but also a safe raw material for edible oils and da... | |

| Organic Membrane Machine Lab & Pilot | In order to meet the scientific requirements of scientific research institutes andenterprises in the early research and development of feed liquid ... | |

| SS Membrane Module | The SS ceramic membrane module is designed by different applications. Stainless steel could be used as the material of module/housing, that is, ss ... | |

| Ceramic Membrane Module | Ceramic Membrane Products A ceramic membrane moduleis a complete unit composed of the ceramic membranes, housing, feed inlet, concentrate outlet, ... |

Same products

| The Ultimate Tool for Bubble-Free Displays | Seller: Shenzhen Wikshu Technology Co. | FORWARD FW-16R Bubble Remover and FW-8R Mini Bubble Removal Machine removes screen OCA bubbles du... | |

| Precision CNC Lathe With Conjoined Oblique Rail Cutter Tower | Seller: Zhejiang Guoyu CNC Machine Tool Co., Ltd. | Technical Characteristics: 45° slant bed base structure, with strict aging treatment, smooth ... | |

| Rail Welder A Frame aligners railway welding tools | Seller: 834406 | 产品描述 A型车架 A-Frame 是一种导轨对准器,可精确对准要焊接的导轨。该设备在焊接操作期间将导轨固定到位。 | |

| 2 parts fluid mixing dispenser 2 component dosing epoxy PU silicon rubber vacuum system | Seller: 824681 | What is the difference between 2K AB adhesive materials manual potting machine and robot pottingm... | |

| Horizontal Machining Center | Seller: Xilong (Shanghai) Machine Tool Co., Ltd. | Horizontal Machining Center parts can automatically finish four sides milling, boring, drilling, ... |