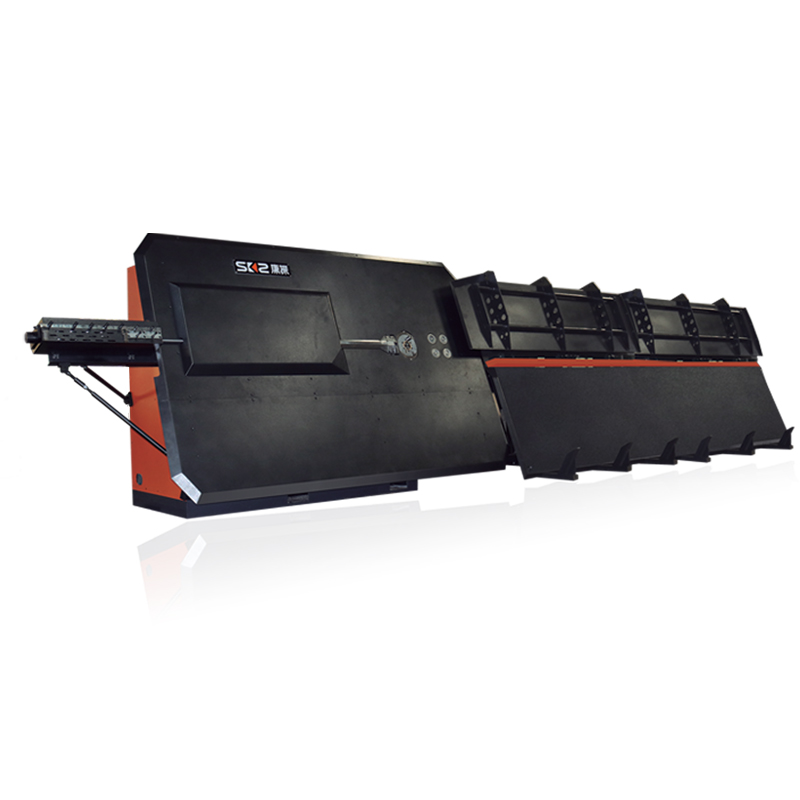

Space saving Integrated Rebar Cutting

A perfect Combination of rebar shear line &rebar bending center

Highlights:This production line is a perfect combination of rebar shearing line and rebar bending centerAn integrated equipment with the function of both shearing and bendingIt realizes lean manufacturing of rebar processingSpace saving: no space required for cut-to-size rebar, the combined machine covers an area of 120㎡Save labor: the machine is with direct consignment, save the labor for lifting and carryingImproved efficiency: process the raw material into semi-finished bends with minimum durationguaranteed quality: the working procedure is closely connected, enables to detect abnormal conditions and correct it without delayEasy operation: equipped with humanized running program and modularized setting. easy to operate

|

Model |

KQW32BX |

||||||||||||||||||

|

Max Shear Foree (KN) |

1750 |

||||||||||||||||||

|

Conveying Speed(m/min) |

≤60 |

||||||||||||||||||

|

Max Steel Strength (MPa) |

570 |

||||||||||||||||||

|

Cutting Langth (mm) |

Manual |

0-1200 |

|||||||||||||||||

|

Automatic |

1200-12,000 |

||||||||||||||||||

|

Culling Capacity |

(φ)(mm) |

10 |

12 |

14 |

16 |

18 |

20 |

22 |

25 |

28 |

32 |

36 |

40 |

||||||

|

17 |

14 |

12 |

11 |

9 |

8 |

8 |

5 |

5 |

4 |

2 |

2 |

||||||||

|

15 |

12 |

11 |

9 |

8 |

7 |

7 |

5 |

4 |

3 |

2 |

2 |

||||||||

|

Average Pewer Consumption (KW/h) |

25 |

||||||||||||||||||

|

Max Bending Angle (°) |

(φ10-φ28) +180 -100(φ32) +90 -90 |

||||||||||||||||||

|

Max Bending Size (mm) |

10500 |

||||||||||||||||||

|

Min Bending Size (mm) |

90 |

||||||||||||||||||

|

Min Bending Size Length (mm) |

(φ10),(630)(φ25),(650) |

||||||||||||||||||

|

Length Tolerance (mm) |

±2 |

||||||||||||||||||

|

Bending Tolerance (°) |

±1 |

||||||||||||||||||

|

Speed Control |

CNC Servo control |

||||||||||||||||||

|

Labeled elechic Power (kw) |

14 |

||||||||||||||||||

|

Moving Speed (m/s) |

|||||||||||||||||||

|

Bending Speed (°/s) |

65 |

||||||||||||||||||

|

Cylinder Pressure (Mpa) |

|||||||||||||||||||

|

Manufacture range |

Strand Diameter φ(mm) |

10 |

12 |

14 |

16 |

20 |

22 |

25 |

28 |

32 |

|||||||||

|

Nos to be sheared (pcs) |

6 |

5 |

4 |

3 |

3 |

2 |

2 |

1 |

1 |

||||||||||

|

Weightlkg) |

4500 |

||||||||||||||||||

Send product request

Other supplier products

| automatic Stirrup bending machine (8-Shaped) | automatic Stirrup bending machine (8-Shaped),bridge Stirrup Bender,real estate Stirrup Bender,reinforcing steel processing factories Stirrup Bender... | |

| Threading Machine | This machine is designed for the steel bar end threading processing,it can finish the thread processing according to request and increase the en... | |

| Integrated Rebar Cutting | Model KZW50X Conveying speed 40 (m/nin) Bending speed 6 […] Model KZW50X Conveying speed 40 (m/nin) Bending speed 6-8r/... | |

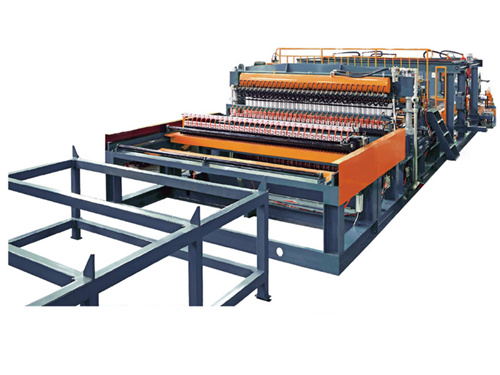

| MESH WELDING MACHINE | MESH WELDING MACHINE,Reasonable layout Mesh Welding Machine,high precision Mesh Welding Machine Reasonable layout Mesh Welding Machine high preci... | |

| cnc wire bending machine (KZ12CX) | This machine is a , which integrates straightening, positive bending and reverse bending forming and cutting four functions in one, steel bar hoo... |