spring cone crusher working principle

This machine consists of frame,transmission device,eccentric bearing sleeve, bowl bearing,crushing cone,adjusting device,adjusting sleeve.feeding part, spring. buffering coupling, hydraulic station etc. Cone crusher has the features of big crushing ratio, less consumable parts and low wearing rate.

During operation, the motor of Cone Crusher drives the eccentric shaft shell to turn around through buffering coupling, transmission shaft and a pair of eccentric bearing sleeve. The axle of crushing cone swings with the force of eccentric shaft shell so that the surface of the crushing wall is close to the roll mortar wall from time to time. In this way, the ores and rocks will be pressed and crooked and crushed.

If you want to know more about our equipments details,please contact us

Shanghai Shuosen Mining Machine Co.,Ltd

|

|

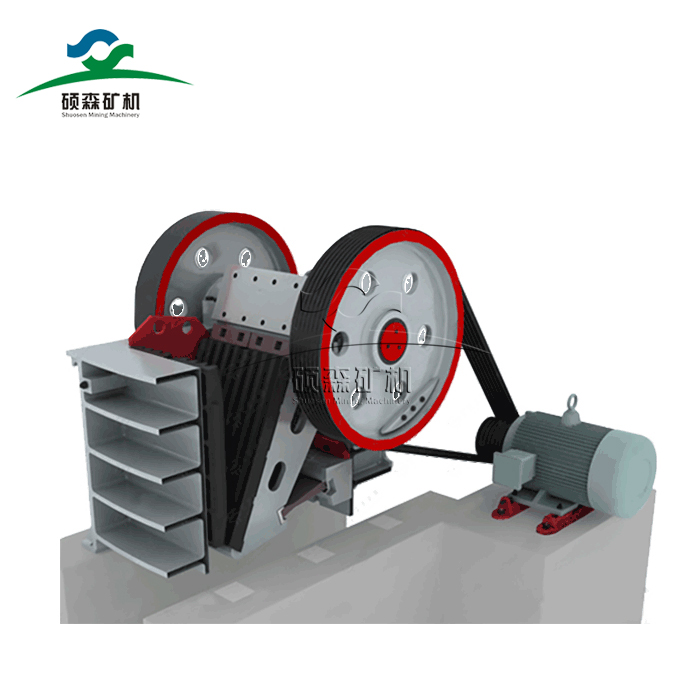

jaw crusher manufacturer |

Application of ore jaw crusher: Jaw crusher is suitable for primary and secondary crushing rocks with compressive strength of 320 MPa. It widely us... |

|

|

hydraulic cone crusher manufacturer |

Max Feeding size: 76-320 mm Power: 160-400 kw Capacity:55-700 TPH Applied material: marble,granite, quartz, pebble,iron ore, talcum, fluorite,gypsu... |

|

|

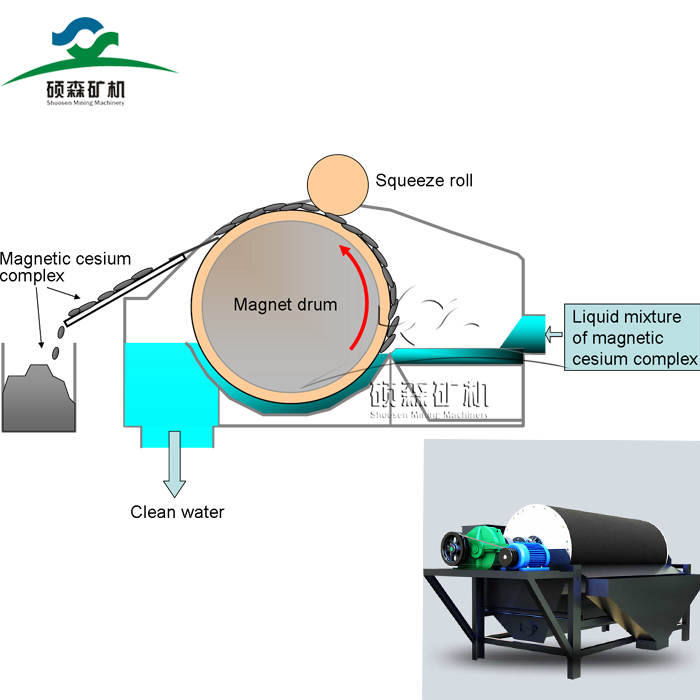

how magnetic separator works |

Operational principle of magnetic separator Through the feed box, ore pulp flows into tank, under the water flow effects of the feeding spray pipe,... |

|

|

stone jaw crusher supplier |

Jaw Crusher Application fields: metallurgy, chemical, building materials, electricity, transportation and other departments. Processing capacity:1-... |

|

|

Hematite Iron Ore Beneficiation Plant |

Overview

The chemical formula of Hematite isFe2O3, red color.

Hardness 5.5 to 6.5. The density is 4.9-5.3 g/cm3.

Hematite is the main mineral fo... |