High temperature vacum friction & wear tester

Main uses:

High temperature vacuum friction and wear testing machine is mainly used to study the friction and wear characteristics of materials in high temperature and vacuum environment. Its exquisite design and comprehensive functions can simulate a variety of practical conditions and provide reliable experimental data for researchers. Specifically, the main uses of the testing machine include:

Materials science research: By simulating the friction and wear process under high temperature vacuum environment, we can deeply explore the friction and wear mechanism of materials, and provide experimental support for theoretical research and application development of materials science.

Aerospace applications: When spacecraft operate in high temperature and vacuum environments, the friction and wear properties of their components are critical. The testing machine can be used to evaluate the high temperature vacuum friction and wear resistance of aerospace materials, and provide a basis for the selection and design of components.

Automotive industry applications: Components such as automotive engines work at high temperatures and in specific atmospheres, and their friction and wear performance directly affects the performance and life of the vehicle. The testing machine can be used to evaluate the wear resistance of auto parts in high temperature vacuum environment, and provide experimental data for improving and optimizing auto parts.

Other industrial applications: In metallurgy, chemical industry, energy and other industrial fields, there are also friction and wear problems in high temperature and vacuum environment. The testing machine can be used to evaluate the high-temperature vacuum friction and wear resistance of materials used in these fields, providing strong support for industrial production and quality control.

Applicable standards:

When conducting high-temperature vacuum friction and wear tests, it is usually necessary to follow certain standards and specifications. Here are some common applicable standards:

ASTM Standards: Relevant standards developed by the American Society for Materials and Testing (ASTM) may contain specific methods and requirements for high-temperature vacuum friction and wear tests. These standards specify the loading method, test temperature, vacuum degree, data recording and other parameters and requirements during the test process.

1SO standard: The International Organization for Standardization (1SO) may also have developed standards related to high-temperature vacuum friction and wear tests. These standards first ensure the accuracy and comparability of test results, and provide a uniform basis for international scientific research cooperation and industrial exchanges.

Other industry standards or enterprise standards: In addition to the general standards mentioned above, different industries or enterprises may also develop specific testing standards. These standards may have specific requirements for specific material types, test conditions or treatment of test results.

It is important to note that different standards and specifications may have different requirements for different types of materials and test environments. Therefore, when conducting high-temperature vacuum friction and wear tests, it should be ensured that the selected standards are consistent with the test purpose and requirements.

Send product request

Other supplier products

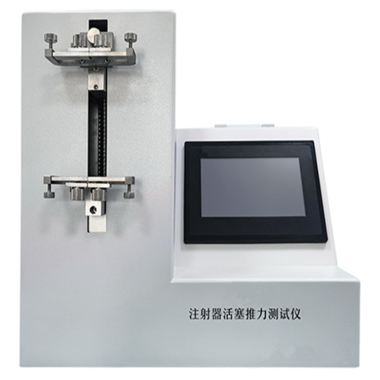

| Syringe piston thrust test device | Product introduction The syringe piston thrust tester is a kind of high precision and high stability measuring equipment, which is used to measure... | |

| SDC Fading Grey Scale | Standards ISO 105-A02(Grey Scale for Assessing Change in Color) AATCC Evaluation Procedure 1(Grey Scale for Stain and Color Change) BS EN ISO ... | |

| Glove Cut Resistance Tester | Product Introduction: The machine is used to test the cutting resistance of gloves. Under the specified load, the blade cuts the sample to measure... | |

| Metal Bone Screws Self - tapping Tester | Standard ISO 6475: Implants for surgery – Wear of total hip-joint prostheses ASTM F543: Standard Specification and Test Methods for Metalli... | |

| FPC Flexibility Endurance Tester (for FPC Flex Durability Tester) | Standard ASTM F392 Product features 1. the stepper motor drive, high-precision positioning, low noise, can be used for a long time 2. program-c... |

Same products

| Plastic Smoke Density Tester F313 | Seller: Standard International Group (HK) Limited | The F313 Plastic Smoke Density Tester is a precision instrument designed to measure the specific ... | |

| Xenon Test Chamber | Seller: Standard International Group (HK) Limited | Features and Benefits 1.The use of xenon arc lamp as a light source, can simulate the full sunli... | |

| Single Cable Vertical Flame Tester | Seller: Qinsun Instruments Co., LTD | Introduction Single Cable Vertical Flame Tester is used for the vertical flame propagation of a ... | |

| Safety Helmet Flammability Tester | Seller: Qinsun Instruments Co., LTD | Product Introduction: Safety hat flame retardant performance tester for safety hat flame retarda... | |

| Furniture flammability tester | Seller: Qinsun Instruments Co., LTD | Product details Furniture flammability tester is mainly used to test the combustion performance ... |