High quality custom aluminum gravity casting Exhaust Pipe

High quality custom aluminum gravity casting Exhaust Pipe

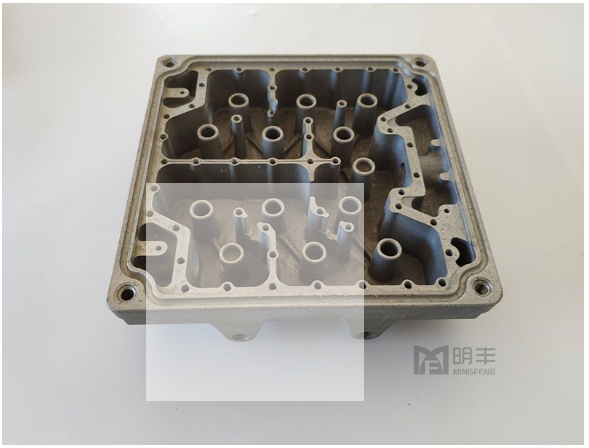

Precision Aluminum CNC Gravity Casting

Gravity casting is a casting process used for non-ferrous alloy parts.

Sometimes referred to as Permanent Mould, the process is typically used on aluminum, zinc, and copper base alloys.

Let’s take a deeper look at the process and some of its benefits.

The Process

There are three stages to the gravity casting process.

The first step is the heat of the mold and coating it with a die release agent. The release agent spray also serves as a cooling agent after the part has been removed from the die.

In the second step, the molten metal is poured into channels in the tool to allow the material to fill the entire mold cavity. The metal is either dosed or hand poured by using ladles. Usually, there is a mold “down sprue” that allows the alloy to enter the mold cavity from the lower part of the die. This reduces the formation of turbulence and subsequent porosity and inclusions in the finished part.

After the part has cooled, the die is opened by either using a mechanical tool or manually.

Advantages

There are many advantages to cnc gravity casting. It offers good dimensional accuracy, a smoother cast surface finish than sand casting, and improved mechanical properties compared to sand casting. Gravity casting also provides faster production times compared to the other processes.

Does Your Project Require Gravity Casting?

Gravity casting is ideal when using non-ferrous alloy parts such as aluminum and zinc. contact us today to learn more about this, as well as the other services we provide.

More information please viewhere.

Send product request

Other supplier products

| China OEM CNC machining metal Parts | China OEM CNC machining metal Parts BENEFITS OF CHOOSING CNC MACHINING CNC Machining, or computer-numerical control machining, is a partially auto... | |

| CNC Turning Parts Custom made mechanical Precision cap | CNC Turning PartsCustom made mechanical Precision cap Technological Process: Stainless steel rod-->Cut down/saw machine-->CNC Lathe-->Pac... | |

| High quality custom aluminum cnc die casting Filter | High quality custom aluminum cnc die casting Filter Precision Aluminum Die Casting Aluminum Die Castingis a process of injection of Aluminum or Al... | |

| Filter | Technological Process: Pressure Casting-->Machining-->Package Size: non-standard Material: Aluminium Precision Aluminum Die Casting Alum... | |

| Generator rotor shaft | Recognizing that customers are looking for value-added suppliers that offer comprehensive service, we also provide competent and efficient mechanic... |

Same products

| Cast iron service | Seller: SHANXI HELIOS CASTING AND FORGING INDUSTRIAL CO., LTD. | Helios own a variety of casting processes, including clay sand horizontal automatic molding line,... | |

| Cast iron service | Seller: SHANXI HELIOS CASTING AND FORGING INDUSTRIAL CO., LTD. | Helios own a variety of casting processes, including clay sand horizontal automatic molding line,... | |

| Inconel Alloy Directional Casting Service: Precision for High-Performance Applications | Seller: Neway Precision Works Ltd | Inconel Alloy Directional Casting Service: Precision for High-Performance Applications Inconel a... | |

| Inconel Alloy Powder Metallurgy Turbine Disc Service: Advanced Manufacturing for High-Performance Components | Seller: Neway Precision Works Ltd | Inconel Alloy Powder Metallurgy Turbine Disc Service: Advanced Manufacturing for High-Performance... | |

| CMSX Series Single Crystal Casting Service | Seller: Neway Precision Works Ltd | Introduction to CMSX Series Single Crystal Casting Service The CMSX Series is a family of advanc... |