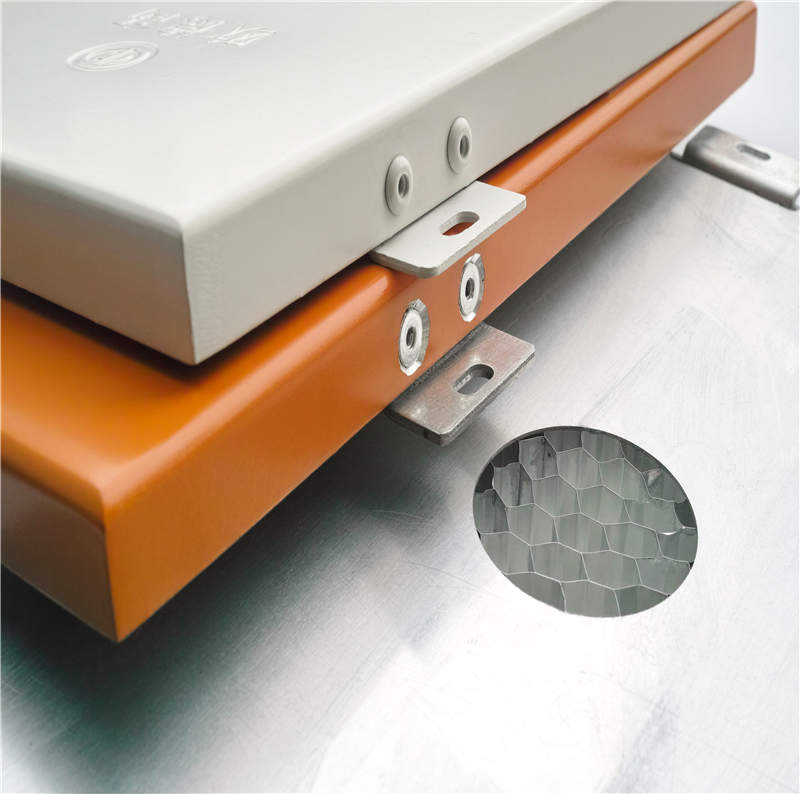

1100 Aluminum Honeycomb Panel

Manufacturers to undertake customized public decoration waterproof aluminum

Product Feature and Application of the Aluminum Honeycomb Core Sandwich Panel

Honeycomb structures are natural or man-made structures that have the geometry of a honeycomb to allow the minimization of the amount of used material to reach minimal weight and minimal material cost. The geometry of honeycomb structures can vary widely but the common feature of all such structures is an array of hollow cells formed between thin vertical walls. The cells are often columnar andhexagonal in shape. A honeycomb shaped structure provides a material with minimal density and relative high out-of-plane compression properties and out-of-plane shear properties.

Man-made honeycomb structural materials are commonly made by layering a honeycomb material between two thin layers that provide strength in tension. This forms a plate-like assembly. Honeycomb materials are widely used where flat or slightly curved surfaces are needed and their high Specific strength is valuable. They are widely used in the aerospace industry for this reason, and honeycomb materials in aluminum, fiberglass and advanced composite materials have been featured in aircraft and rockets since the 1950s. They can also be found in many other fields, from packaging materials in the form of paper-based honeycomb cardboard, to sporting goods like skis and snowboards.

|

ITEM |

DETAILS |

|

Product Name |

Aluminum Honeycomb Panel |

|

Aluminum Alloy |

1100,3003 |

|

Panel thickness |

|

|

Max size |

2000*7000mm |

|

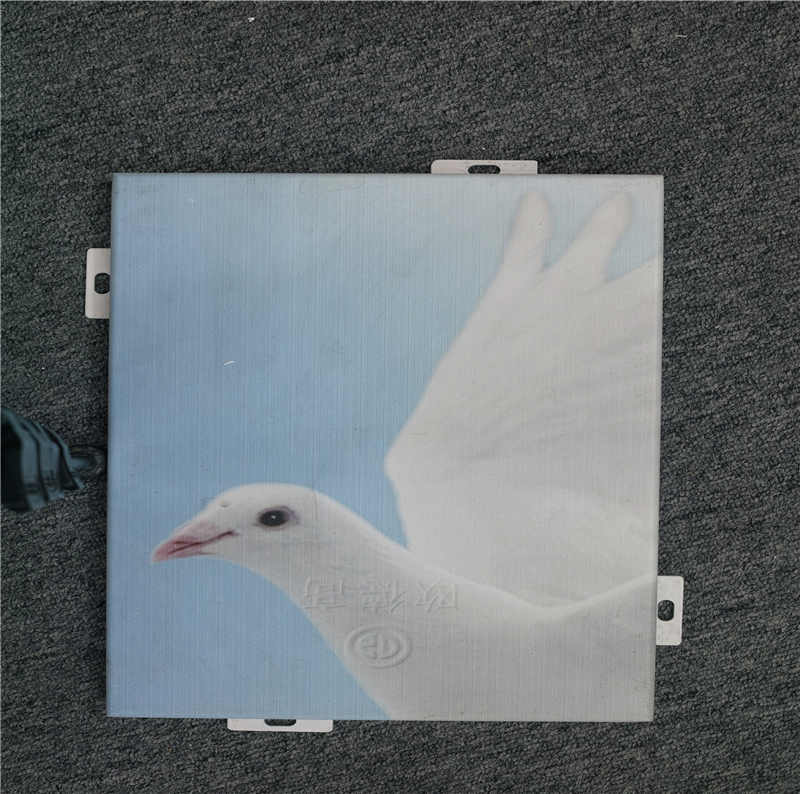

Surface treatment |

PVDF 2/3/4 Layer coating |

|

Powder coating |

|

|

Wood grain (wood grain paper /Therminal transfer printing / wood grain painting) |

|

|

Stone grain (stone grain painting / Therminal transfer) |

|

|

Color |

RAL color, Pantone color |

|

Shape |

Flat, cambered, double curved, triple curved, spherical, customized shaped. |

|

Warranty |

Max 25 years guarantee for ideal application evvironment |

|

Packaging |

Carton package |

|

Leadtime |

15-20 days after receiving the deposit and confirm the details |

Technical Details of Aluminum Honeycomb Core Sandwich Panel

Technical Details of

|

Thickness |

20mm |

25mm |

|

Aluminum surface plate |

||

|

Aluminum reverse plate |

||

|

Weight (kg/m2) |

||

|

Mechanical properties of composite panels and panel |

||

|

Moment of inertia I (cm4) |

||

|

Section modulus W(cm3) |

19 |

19 |

|

Composite plate stiffness E.I(KN cm2) |

139000 |

139000 |

|

Aluminum panel |

AA5754A(ALMg3) |

|

|

Modulus of elasticity (N/mm2) |

70000 |

|

|

Panel tensile strength (N/mm2) |

Rm≥220 |

|

|

Elongation (EN485~2:1194) |

A50≥8 |

|

|

Aluminum linear heat expansion |

||

|

Surface decoration Layer |

PVDF Spray and bake paint |

|

|

Gloss (initial value) |

30-40% |

|

|

Pencil hardness |

HB-F |

|

|

Honeycomb core |

||

|

Cellular size |

1/4''(6.3mm) |

|

|

Lead material capacity |

About 80kg/m3 |

|

|

The compressive strength (MIL-STD-401) |

4N/mm2 |

|

|

Acoustic performance |

||

|

Absorption coefficient AS |

||

|

Sound insulation coefficient (According to ISO717-RW) |

23 |

25 |

|

The thermal performance |

||

|

Coefficient of thermal conductivity (w/m2k) |

||

|

Thermal resistance R(1/m) (m/m2k) |

||

|

Heat transfer coefficient U(K) (M/M2K) |

||

a. Light weight, Good rigidity, high strength and safety

Theweight is only 1/70 of that for bricks and 1/3 of that for stainless steel.

b. Fireproofing Properties

Tested by National Research Center of Testing Techniques For Building Materials, the properties of meet the requirement of non-flammable materials. According to GB-8624-1997 Standard, the aluminum honeycomb panels fireproofing grade is GB-8624-B1 Grade.

c. Super Flatness and Rigidity

The special hexagonal structure of aluminum honeycomb panel is composed of many dense hexagonal cells and these cells are similar to many I shapes, which averagely take the pressure from the panel surface. The property assures the high compression strength and super flatness over a large area.

d. Sound Insulating, Heat Insulation, Heat Preservation

Between the two skins are divided into many closed and independent cells, which to a great extent limit the transmission of sound wave and heat.

e. Moisture resistance , Corrosion Resistant

The surface skins are manufactured through roller-coating techniques, thus anti-anodizing, color-stable and no going moldy and deforming. According to testing, the aluminum honeycomb panel remains intact after immersed in 2% HCL solution or in saturated Ca(OH)2 Solution for 24 hours.

f.Environmentally Friendly

High quality aluminum single solid panel for ceiling could be recycled absolutely which is different with other material. And aluminum honeycomb panels does not emit any hazardous gas and easy to be cleaned and also easily recyclable.

Here is Shunde Goodwill Metal Work which produces Aluminum Wall Cladding, Aluminum Solid Panel, Aluminum Honeycomb Panel.We are professional .

Send product request

Other supplier products

| Aluminum Strip / Linear Ceiling | Metal Ceiling Strip Aluminum Suspended Decorative False Ceiling Design With Building Materials is kind of visible curtain type ceiling. The visu... | |

| Decorative aluminum waterproof ceiling tile perforated metal sheet for Commercial Building | Decorative aluminum waterproof ceiling tileperforated metal sheet for Commercial Building Aluminum Ceiling Tile Product Description ITEM... | |

| Factory Price Customized 3D Printed Solid Aluminum Construction Materials Panel | Factory Price Customized 3D Printed Solid Aluminum Construction Materials Panel ITEM 3D priting Aluminum ceiling panel Pro... | |

| Fashionable Metal Ceiling Serie Aluminum Baffle Ceiling Cladding Design For Interior or exterior decoration | Fashionable Metal Ceiling Serie Aluminum Baffle Ceiling Cladding Design For Interior or exterior decoration Aluminum baffle ceiling is kind of v... | |

| Architectural Aluminium Perforated Facade Panel for Buildings | for Buildings Aluminum Perforated Panel ITEM DETAILS Product Name Aluminum Perforated Panel Aluminum Alloy 1100,3003 Panel th... |

Same products

| Explore For Sale Aluminum Scrap Extrusion 6063-6061, aluminum 6063 scrap supplier | Seller: Ivory Global JP Scrap Co | At our collection center, specializing in the export of diverse aluminum varieties, our inventory... | |

| Aluminum discs for cookware 1050 1060 3003 Aluminum discs for non-stick pans wholesale | Seller: Henan Hongchang Aluminum Co., Ltd. | The lightness and excellent thermal conductivity of aluminum alloy make it a high-quality materia... | |

| Extrusion 6063 scrap aluminum For Sale, Aluminum 6063 | Seller: I Global Scrap Trading Co. | Our collection, which specializes in the exporting of diverse aluminum varieties, consistently co... | |

| 1050 1060 1100 3003 ex-factory price of aluminum discs for non-stick pans | Seller: Henan Hongchang Aluminum Co., Ltd. | Aluminum alloy is the most commonly used cookware material in the world because of its light weig... | |

| 6082 Aluminium Tube | Seller: China Aluminium Industry Supply Chain (Tianjin) Co., Ltd | 6082 Aluminium Tube 6082 aluminium tubeis a medium strength alloy with excellent corrosion resis... |