MFL101 Tank Floor MFL Scanner

Technical Characteristics of MFL101 mfl tank floor inspection

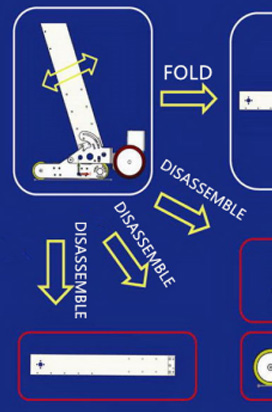

The mfl tank floor scannerhas a unique full modular structure, from the main body of the computer mechanism the handle of MFL101 tank floor scannercan be quickly folded, disassembled. It is easy to transport and access manholes. With humanized operation design, the height of armrest and adjustable angle, suitable for different operators. Precise signal conditioning circuit. The four-layer PCB with mixed power excellent performance. data word signal processing system, supercomputing power, advanced evaluation algorithm.

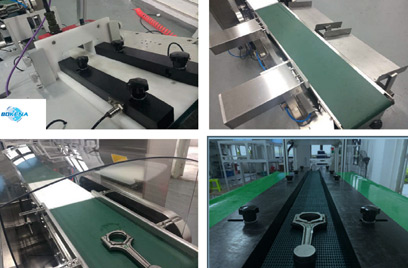

High-performance touch industrial tablet. The operation is very convenient does not require a keyboard and mouse. Unique probe design. It can pick up the magnetic flux leakage signal to overcome the unwanted signal caused by the eddy current effect. The number of physical channels is up to 32. High-performance lithium battery pack, which is at least 50% lighter than the equivalent capacity lead-acid battery Software design that can be operated efficiently.

All scan parameter settings graphical, intuitive, and easy to use, dramatically increasing the speed of operation and avoiding errors. The magnetization is quickly adjustable. By adjusting the ground clearance the magnetic pole, the magnetization of the detection target plate can be quickly changed to meet the requirements of detecting the thickness and minimize the gravity of the instrument and the bottom plate. This design allows the instrument to adapt to a wide range of floor thicknesses and reduce operator effort, increasing battery life.

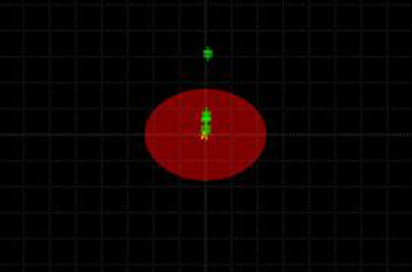

Different degrees of corrosion are represented by non-color blocks. Online analysis of corrosion degree and position, position coordinates can be displayed in a table or on a scan.

MFL101 Tank Floor MFL Scanner Performance Parameters Host:

Industrial tablet computer interface:

Chinese Working principle: Magnetic flux leakage method:

NdFeB permanent magnet Channel number: 32

Scan width: 260mm

Drive mode: DC brushless motor, worm gear reducer, The motor can be raised.

Convert manual and electric drives at any time.

Detection speed: 0 m / s~0.7m /s step-less adjustable

Detection thickness: 8-20mm Penetration coating: non-magnetic

Penetration thickness: <4mm

Sensitivity: can be set (8-12mm thick 20 % material loss of the bottom plate, 40% material loss of the 12-20mm thick bottom plate

Data storage: local hard disk storage, USB disk dumping

Real-time analysis: Yes

Offline software

Battery specification: 14V40AH

BKN is one of professional ultrasonic testing equipment manufacturers. We provide Magnetic Flux Leakage Testing, ndt ultrasonic testing equipment, eddy current testingand so on. Want to know more? Please contact us. Now this mfl scannerprice is very reasonable.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Bolt Eddy Current Sorter BKNFX-11 | Bolt: Mechanical parts, cylindrical threaded fasteners with nuts. A type of fastener consisting of a head and a screw (a cylinder with an external... | |

| Оборудование для вихретокового контроля для труб, проволоки | ECT Eddy current testing is a non-contact testing method, which mainly uses the electromagnetic field and electromagnetic induction between metals ... | |

| Eddy Current Testing Equipment | Automatic EDM Notchis the ideal equipment for processing artificial defects of pipe rod standards in non-destructive testing work. The flaw detecto... | |

| EDM Notch | Nanjing BKN Automation System Co., Ltd., originated from the eddy current testing laboratory of the Nanjing University of Technology. It is an eddy... | |

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | Eddy current testing of welds is the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossle... |