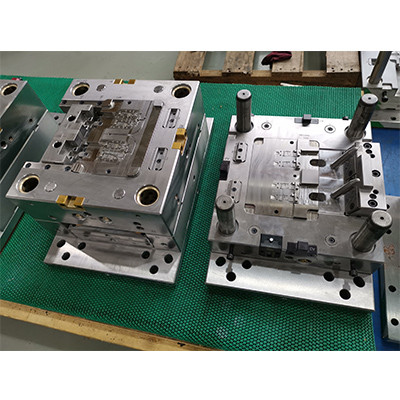

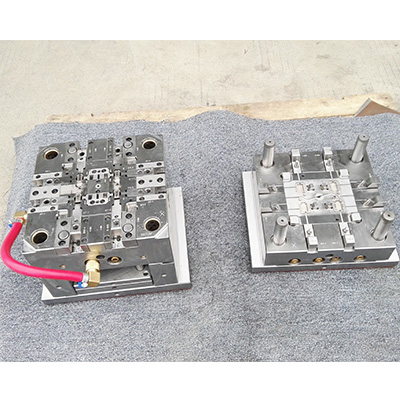

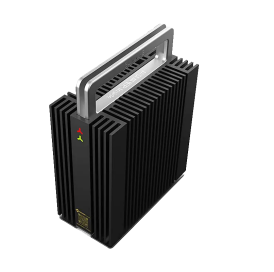

ABS Plastic Injection Mold 49443

Brief Introduction of Hanking ABS molds

Mould Name: Plastic Injection ABS Molds

Part Material: ABS

Product Size: 172*123 mm

Product Description: clear window

Mould Cavity: 1 Cavity

Mould Size: 300*380*250 mm

Mould Cavity Steel: ASSAB 8407

Mould Injection System: hot runner

Mould Ejection System: Round ejector

Mould Cycle Time: 38s

Mould Life Cycle: 500,000

Lead Time: 42 working days

Mold export to: Europe

For ABS plastic part molds, HanKing will make good plastic injection mold design from wall thickness, draft angle, venting, ejector system, balance and a good runner.

Design for ABS Plastic Injection Molds

The wall thickness of the product is related to the flow length of the melt, production efficiency, and use requirements. The ratio of the maximum flow length of the ABS melt to the wall thickness of the product is about 190:1. This value will vary depending on the grade. Therefore, the wall thickness of the ABS product should not be too thin. For products has electroplating requirement, the wall thickness should be slightly thicker to increase the adhesion of the coating to the surface of the article. For this purpose, the wall thickness of the product is preferably between 1.5 and 4.5 mm.

When considering the wall thickness of the product, we should pay attention to the uniformity of the wall thickness, do not make big difference wall thickness. For the products to be electroplated, the surface should be flat without unevenness, because these parts are difficult to remove due to static electricity, which is difficult to remove. The fastness of the coating deteriorates. In addition, the presence of sharp corners should be avoided to prevent stress concentration. Therefore, it is advisable to use arcs for transitions such as corners and thick joints.

The draft angle of the product is directly related to the shrinkage rate. Due to the different grades, the different shapes of the product and the different molding conditions, the molding shrinkage rate has a certain difference, generally 0.3~0.6%, sometimes It is 0.4~0.8%, so its product molding size accuracy is high. For the ABS product, the draft angle is considered as follows: the core portion is 31° in the demolding direction, and the cavity portion is taken 4 (/1° 20' in the stripping direction. For products with complex shapes or letters and patterns, the draft angle should be appropriately increased.

Since the products surface finish has a great influence on the electroplating performance, any slight scratch on the surface will be apparently exposed after electroplating, so that no damage is allowed on the cavity. It is also required a large effective area for ejection, good synchronization of the multiple ejector pins in the ejection process, and uniform ejection force.

In order to prevent the occurrence of poor venting in the process of filling, cause melt burning, the obvious seam line and other problems, it is required to open a vent hole or venting groove in which the depth is not more than 0.04mm, so the gas can be exhausted.

HanKing Mouldis a professional two shot moulding ltd, we provide custom plastic molding china, injection moulding, plastic plate mouldand etc. Want to know abs injection molding processor how to mold abs plastic? Please contact us.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Plastic Insert Mold | Plastic Insert Mold 139-86 Mould Name: Plastic Insert Mold Part Material: PA + Glassfiber Product Size: 11*30*1.3 Product Description: St... | |

| Automotive Mold | Hanking mouldingserves global Automotive & Vehicle products customers, more than 10 years of experience enabling the HanKing team to provide cu... | |

| Insert Molding Technologies for Automotive Industry | Insert Molding Technologiesfor Automotive Industry Mould Type: Automotive Sensor Plastic Injection Mould Production Material: Nylon PA66 No ... | |

| Производство литьевых форм | HanKing Mould имеет такие преимущества, как низкие затраты на рабочую силу, короткое время изготовления пресс-форм, отличное оборудование и возможн... | |

| Precision Mould | How to build a high precision mould? We have been manufacturing plastic precision moulds for more than ten years. With our expertise and experien... |

Похожие товары

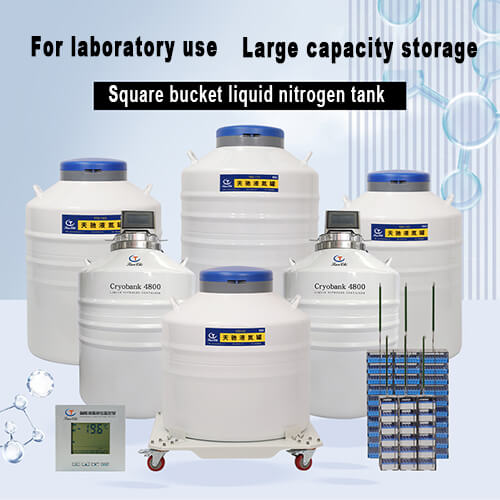

| Резервуар с жидким азотом для Боснии и Герцеговины для лаборатории KGSQ | Продавец: Хэнань Тяньчжидао Биотехнология Лтд. | В лабораториях чаще всего используются резервуары с жидким азотом, имеющие большую вместимость, б... | |

| Хранение сперматозоидов в Танзании Сосуд KGSQ ln2 | Продавец: Henan Tianzhidao Biological Technology Co., Ltd. | В лабораториях чаще всего используются резервуары с жидким азотом, имеющие большую вместимость, б... | |

| Ebike Battery | Продавец: Shenzhen Worldpower Energy Storage Technology Co.,Ltd | Custom Ebike Lithium Battery Manufacturer Elevate your electric biking experience with Worldpowe... | |

| Battery Energy Storage Systems | Продавец: Shenzhen Worldpower Energy Storage Technology Co.,Ltd | Battery Energy Storage Systems (BESS) are cutting-edge technologies that store electrical energy ... | |

| ETH Ethereum Jasminer X4 BRICK ASIC Miner | Продавец: Shenzhen Dovina Electronic Co.,Ltd | Jasminer X4 Brick Review Jasminer x4 brick for salefrom Jasminer mining EtHash algorithm with a ... |